Multi-layer breeding frame for whole-age factory silkworm breeding

A multi-layer and framework technology, applied in animal husbandry, etc., can solve the problems affecting silkworm breeding effect, low annual output of silkworm cocoons, and poor breeding environment, so as to facilitate ventilation and silkworm activities, and improve breeding effect , Increase the effect of breeding space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

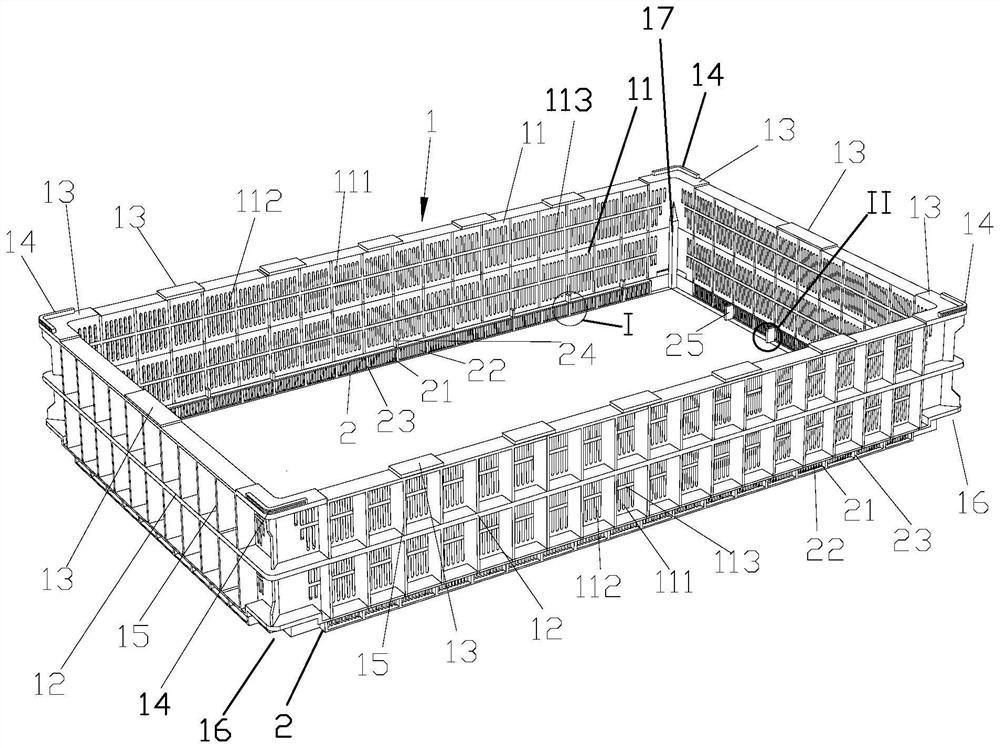

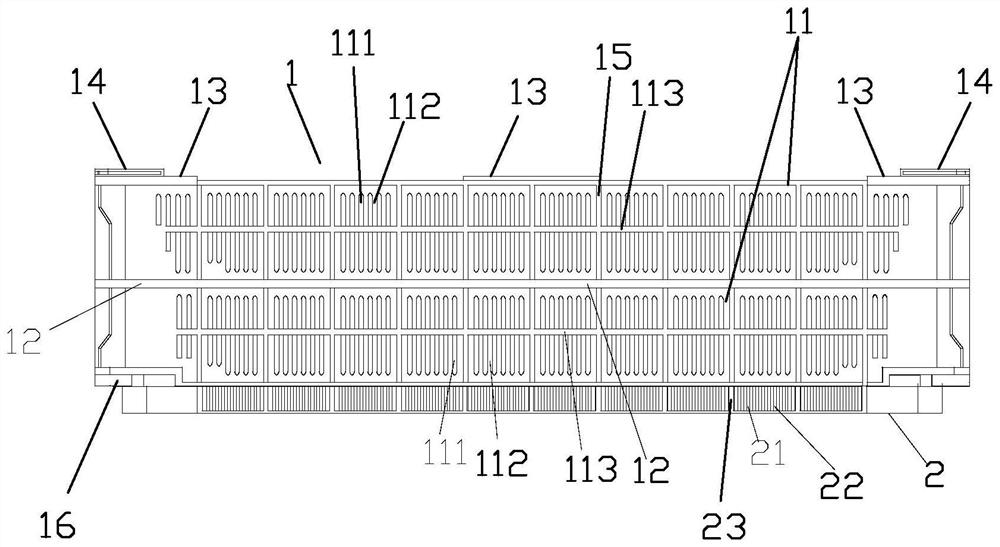

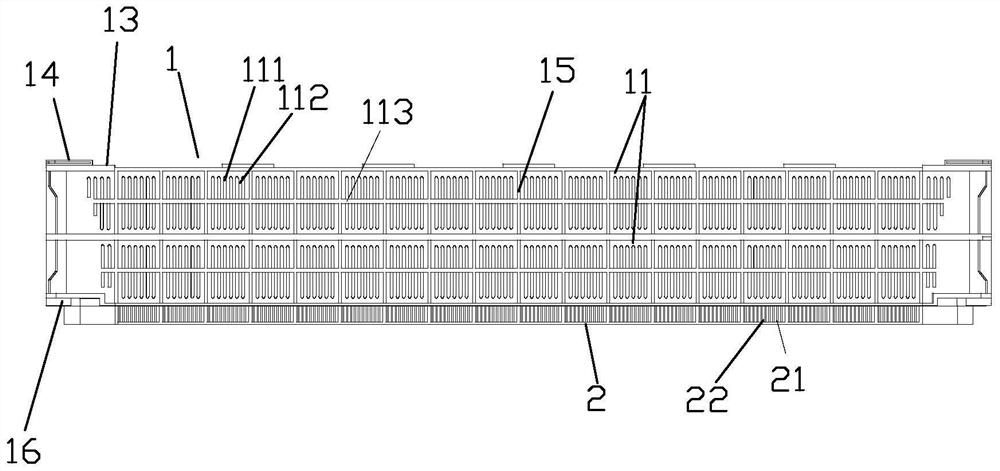

[0035] like Figure 1 to Figure 5 As shown, a multi-layer breeding frame for full-age industrial sericulture includes a frame body 1, and the top and bottom of the frame body 1 are connected. The culture frame is designed based on the culture frame, and its top and bottom are connected. Based on the structural characteristics of the connection, the silkworm excrement and impurities produced during the breeding process can fall, avoiding the problem of bacterial growth in the frame; maintaining the breeding environment in the breeding frame is conducive to silkworm breeding and improves the breeding effect.

[0036] The inner side of the frame body 1 is provided with a supporting and positioning member, and the breeding apparatus is supported and positioned by the supporting and positioning member. The present invention positions and supports the cocoon cages placed in the breeding frame through the supporting and positioning member, so that the cocoon cages can be placed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com