Airing device for transmission type blade production

A drying device and transmission-type technology, which is applied in the field of drying devices for the production of transmission-type leaves, can solve the problems of affecting the drying efficiency of leaves and the inability to quickly discharge the moisture of leaves in the transparent glass cover, so as to improve the drying efficiency and speed up the drying process of the air. effect of circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

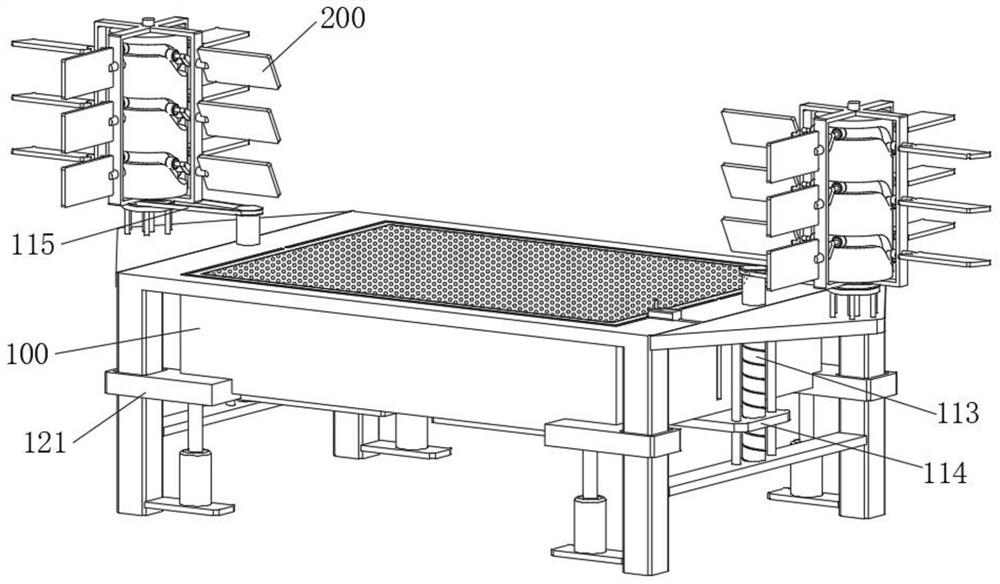

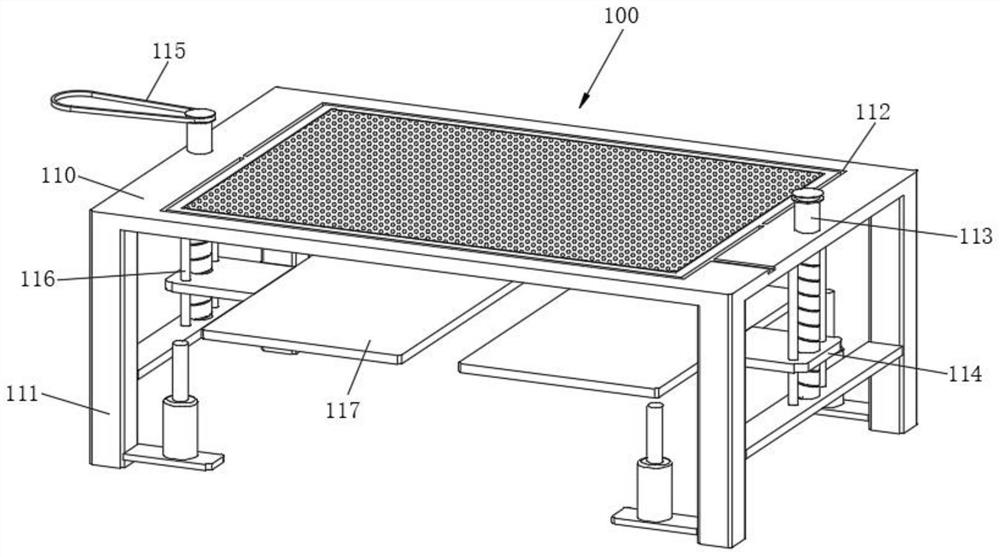

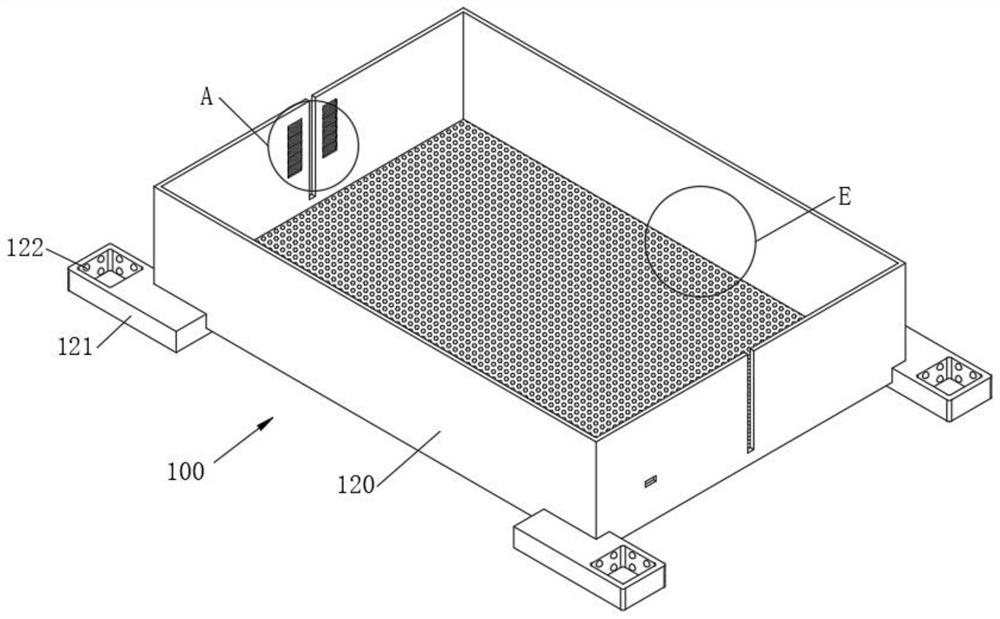

[0049] see Figure 1-Figure 9 As shown, a drying device for driving blade production is provided, including a protection device 100 and a driving device 200 arranged above the protection device 100. The protection device 100 includes a drying platform 110, and the four corners of the bottom of the drying platform 110 are fixedly connected with supports. Rod 111, the surface of the drying platform 110 is provided with a through groove 112, the two ends of the surface of the drying platform 110 are rotatably connected with a screw rod 113, the outer wall of the screw rod 113 is threaded with a transmission plate 114, and the inside of the through groove 112 is slidingly connected with a housing 120 , the top of the housing 120 is provided with an opening, the four corners of the bottom of the housing 120 are fixedly connected with the limit block 121, the limit block 121 is sleeved on the outer wall of the support rod 111 and is slidably connected with it, and the bottom of the h...

Embodiment 2

[0058] In order to improve the airing efficiency to blade, carry out following improvement on the basis of embodiment 1:

[0059] see Figure 10 As shown, wherein, the surface of the drying platform 110 is provided with an empty groove 130, and a drying plate 131 is arranged in the empty groove 130. The surface of the drying plate 131 is provided with a filter hole, and the breeze can be blown from the airing platform 110 through the filter hole. The lower part flows to the top of the drying platform 110. During this process, the breeze contacts the leaves and takes away the evaporated gas in the leaves, so as to speed up the circulation of the air, so as to improve the drying efficiency of the leaves.

Embodiment 3

[0061] In order to realize that the dust in the blade is removed, the following improvements are made on the basis of Embodiment 2:

[0062] see Figure 11-Figure 14 As shown, wherein, the side wall of the empty slot 130 is fixedly connected with a support plate 132, the surface of the support plate 132 is provided with a connecting spring 133, the top of the connecting spring 133 is fixedly connected with the bottom of the drying plate 131, and the drying plate 131 and the empty slot 130 There is a gap between them, the bottom of the drying plate 131 is fixedly connected with a clamping plate 134, the clamping plate 134 is in an “L” shape, one end of the clamping plate 134 is in a triangular structure, and the side wall of the housing 120 has a The matching card slot 135, when the housing 120 rises, the housing 120 drives the card slot 135 to rise, and the card slot 135 rises to contact with one end of the card plate 134, because one end of the card plate 134 and the triangul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com