Melt-blown cloth electrostatic attenuation treatment device and test method

A technology for electrostatic attenuation and processing devices, which is applied in the direction of measuring devices, suspension and porous material analysis, instruments, etc., and can solve the problems of inconvenient electrostatic attenuation testing of melt-blown cloth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

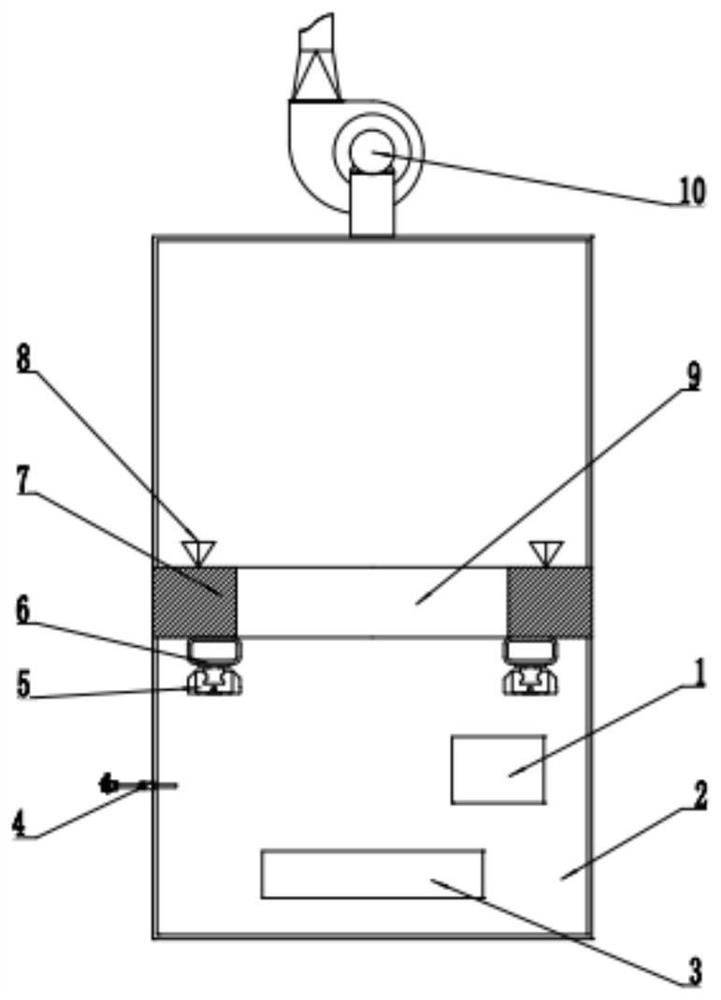

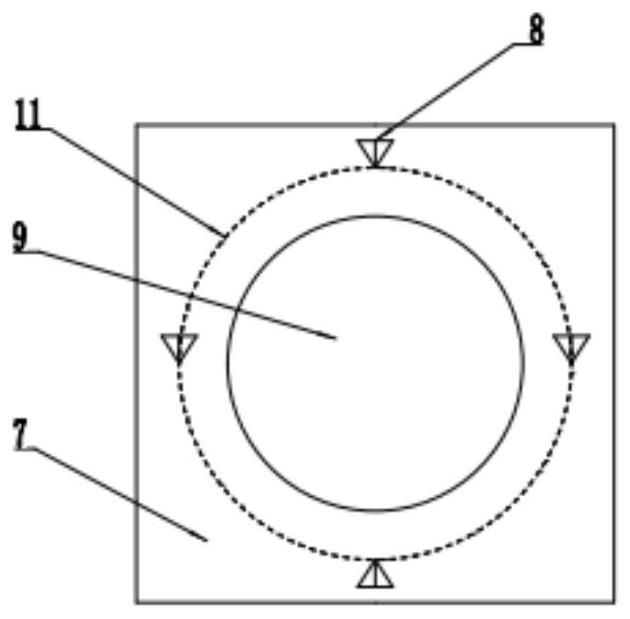

[0028] Such as Figure 1-2 As shown, a melt-blown cloth electrostatic attenuation processing device includes a box body 2, an intelligent control unit 1, a humidification unit, an exhaust unit and a sample placement unit, and the humidification unit, the exhaust unit and the sample placement unit are all connected to the intelligent control unit. The unit is electrically connected; the humidification unit is located at the bottom of the box, including a humidifier 3 and a humidity sensor 4; the sample placement unit is located in the middle of the box, and includes a sample placement platform 7, and the middle of the sample placement platform 7 is provided with Hollowed out sample processing area 9, sample fixing fixtures 8 are uniformly arranged along the circumference of the sample processing area, the lower surface of the sample placement table is connected to sliders 6, and the sliders 6 are arranged on the guide rails 5 on both sides of the box body Above, the slider can ...

Embodiment 2

[0037] A method for testing the electrostatic decay of melt-blown cloth, using the processing device described in the above-mentioned embodiment 1 to test, comprising the following steps:

[0038] (1) Sample preparation: cut the sample to be tested so that the sample size can completely cover the sample processing area;

[0039] (2) Parameter setting: set the humidity and wind speed parameters of the processing device, wait for balance, and place the sample when the humidity display reaches the set value;

[0040] (3) Place the sample: Under the action of the servo motor, the sample placing platform slides out of the box along the guide rail, and the cut sample is placed on the sample placing platform, which is placed flat and without wrinkles, and the center of the sample is aligned with the center of the sample processing area. Then use the sample fixing fixture to fix the sample, and then start the servo motor to drive the sample placement table into the box after placing i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com