Electrode for electrolysis

An electrode and coating technology, applied in the direction of electrodes, electrolysis components, electrolysis process, etc., can solve problems such as overvoltage and reverse current deterioration, and achieve the effects of excellent overvoltage, excellent alkaline durability, and excellent conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

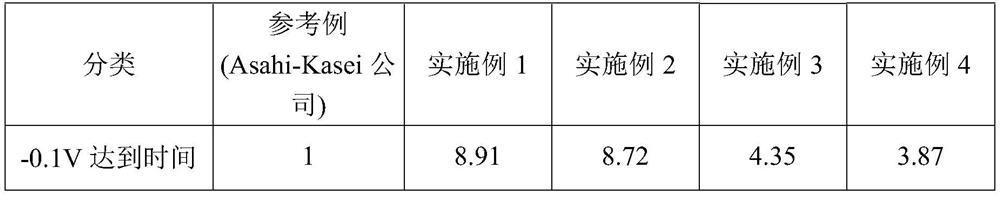

Examples

preparation example Construction

[0041] In the method for producing an electrode for electrolysis of the present invention, the metal base may be the same as that of the electrode for electrolysis described previously.

[0042] In the method of preparing an electrode for electrolysis of the present invention, the coating composition may contain a ruthenium precursor, a cerium precursor, and a nickel precursor. After coating, the precursors are converted to oxides by being oxidized in a heat treatment step.

[0043] The use of the ruthenium precursor may not be particularly limited as long as it is a compound capable of forming a ruthenium oxide, which may be, for example, a hydrate, hydroxide, halide or oxide of ruthenium, and may be specifically selected from Ruthenium hexafluoride (RuF 6 ), ruthenium(III) chloride (RuCl 3 ), ruthenium(III) chloride hydrate (RuCl 3 ·xH 2 O), ruthenium(III) bromide (RuBr 3 ), ruthenium(III) bromide hydrate (RuBr 3 ·xH 2 O), ruthenium iodide (RuI 3 ) and at least one o...

Embodiment 1

[0068] Mix 1g of ruthenium precursor, 0.3135g of cerium precursor, 0.057g of nickel precursor and 0.1625g of platinum group precursor in 10ml of the mixed solvent of the above materials at a molar ratio of 5:0.75:0.25:0.5, so that the concentration of ruthenium is 100g After / L, 0.181 g of urea was added at a molar ratio of 3.13 as an amine additive. The mixed solution was stirred overnight at 50° C. to prepare a coating composition. The coating composition is coated on the pretreated nickel substrate, and the coated nickel substrate is placed in a convection drying oven at 180°C for 10 minutes to dry, and then placed in an electric heating furnace at 500°C for heat treatment for 10 minutes. After the above coating, drying and heat treatment process was repeated 9 times, the final electrode for electrolysis was finally prepared by performing heat treatment at 500° C. for 1 hour in an electric heating furnace.

Embodiment 2

[0070] An electrode for electrolysis was prepared in the same manner except that the molar ratio of the ruthenium precursor, the cerium precursor, the nickel precursor and the platinum group precursor in Example 1 was 5:0.5:0.5:0.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com