Full-automatic typesetting and blanking machine for rubber sealing gaskets

A rubber gasket, fully automatic technology, applied in metal processing and other directions, can solve problems such as low processing efficiency, achieve high blanking efficiency, avoid random falling, and speed up cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

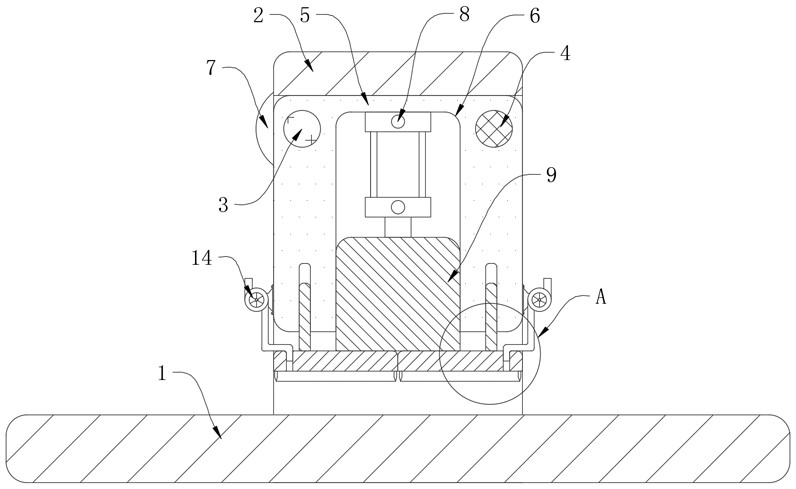

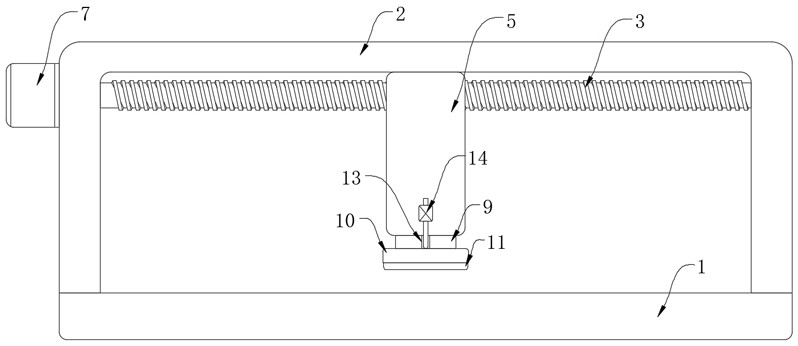

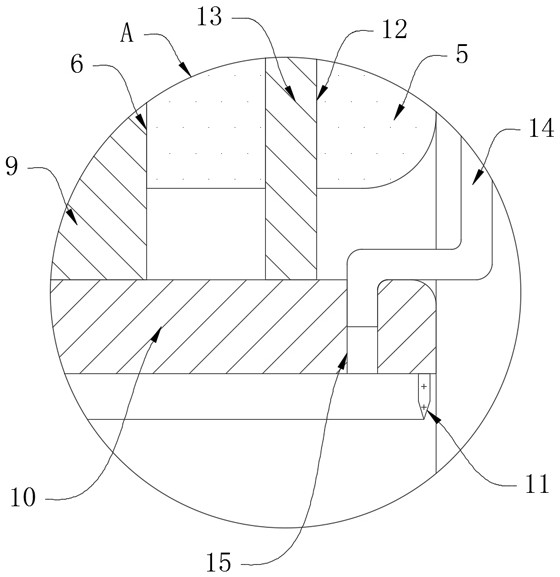

[0014] refer to Figure 1-3 , a rubber gasket automatic typesetting blanking machine, including a base 1, the upper end of the base 1 is fixed with a support frame 2, the inner walls on both sides of the support frame 2 are connected with an adjustment rod 3 through bearing rotation, the adjustment rod 3 is a screw rod, The circumferential side wall of the adjustment rod 3 is threadedly connected with a sliding block 5, the inner walls at both ends of the support frame 2 are jointly fixed with a guide rod 4, the bottom of the sliding block 5 is provided with a vertical groove 6, and one side end of the support frame 2 A motor 7 is fixed, and the motor 7 can be reversed. The main shaft of the motor 7 runs through the support frame 2 and is fixed with the end of the adjustment r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com