Combined adapter for blowdown of air bag

An adapter and combined technology, which is applied in the direction of drainage, mine/tunnel ventilation, safety devices, etc., can solve the problems of sewage valve installation, etc., and achieve the effect of saving processing costs, reducing the risk of damage, and reducing the number of openings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

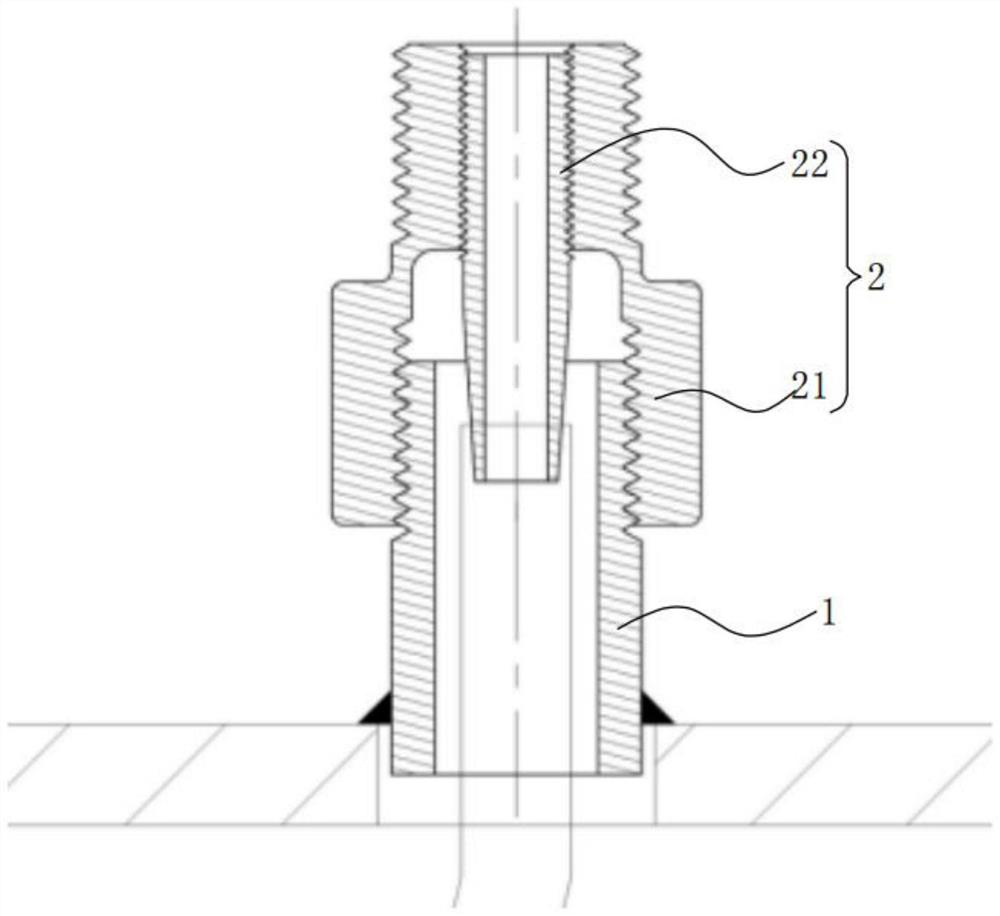

[0034] Please refer to figure 1 ,in, figure 1 It is a schematic structural diagram of the first embodiment of the combined adapter for blowdown of the wind bag provided by the present invention. The combined adapter for wind bag sewage discharge includes: an outer wire joint 1 arranged on the air bag and an adapter 2 for connecting with the outer wire joint 1, and the adapter 2 includes an inner and outer wire conversion joint 21 and an outer wire discharge core Pipe 22, the top of the inner surface of the inner and outer wire conversion joint 21 is provided with threads, and the outer wire discharge core tube 22 is provided with threads corresponding to the inner and outer wire conversion joint 21, and the outer wire discharge core tube 22 can be Screw the outside of the inner and outer wire conversion joint 21 by thread.

[0035] Outer wire connector 1 is positioned on the wind bag, and there are a plurality of outer wire connectors 1 on the air bag, and the tapered end at...

no. 2 example

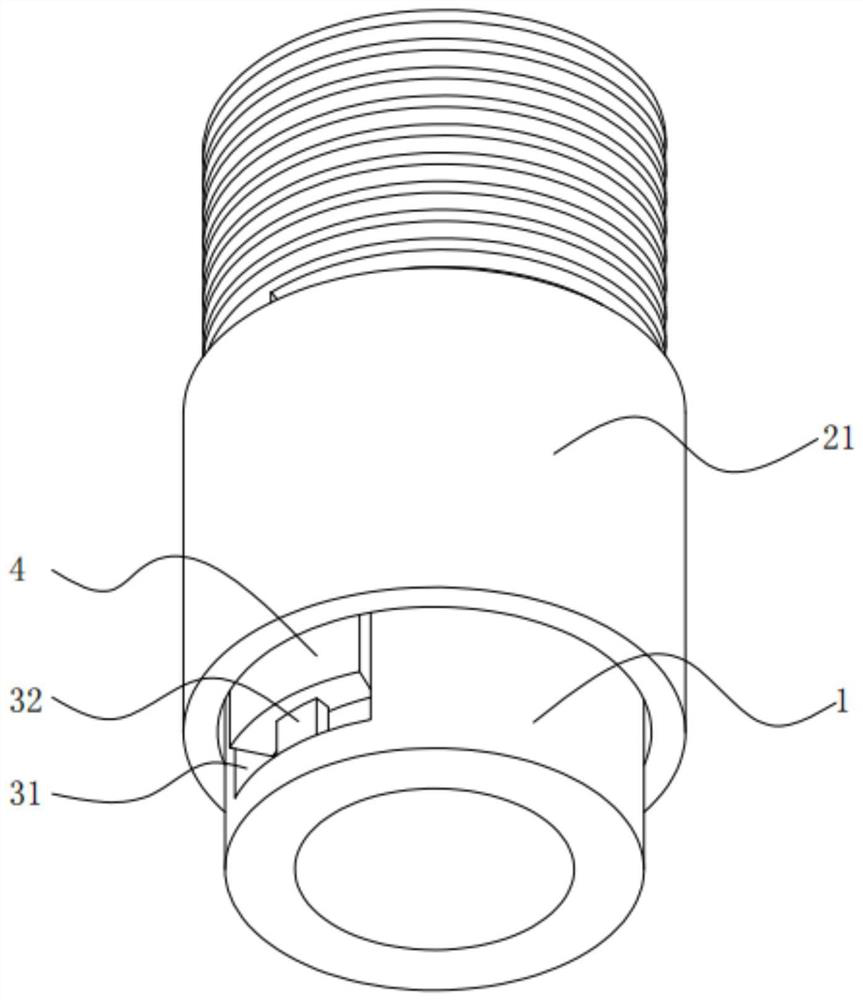

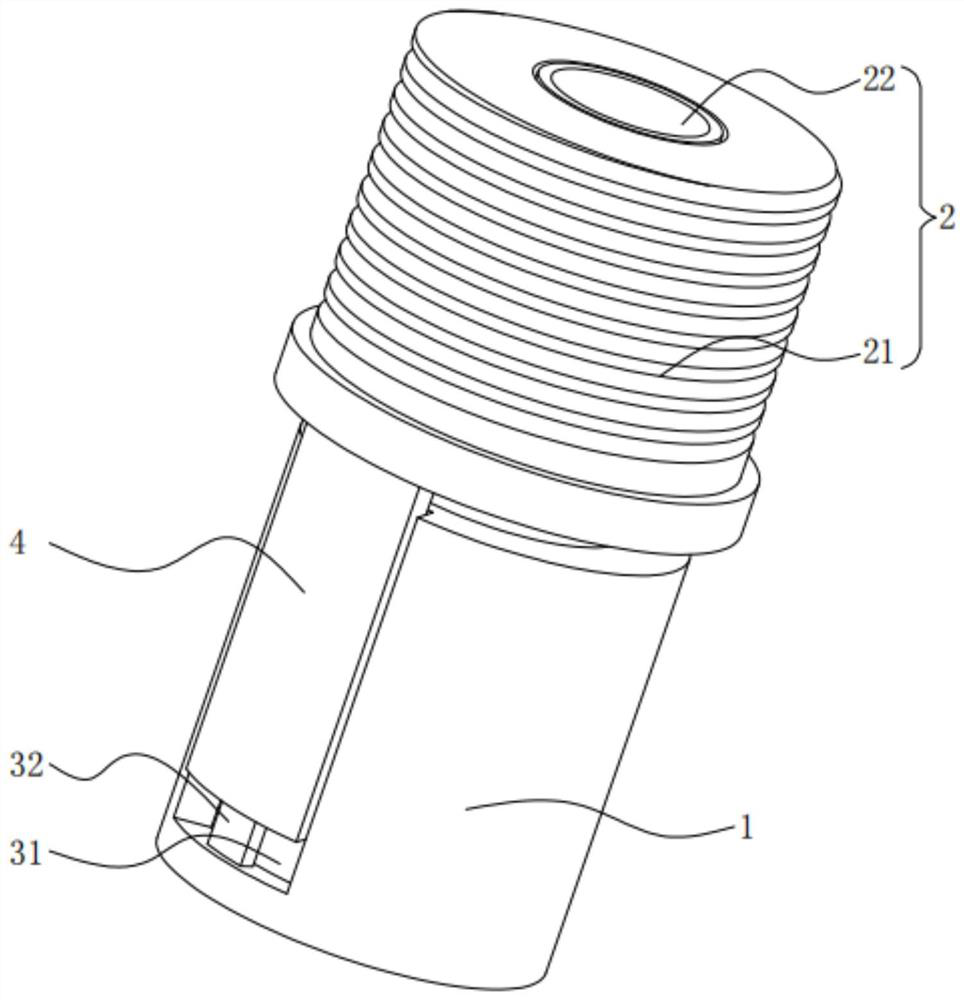

[0043] Please refer to Figure 2-5 According to the first embodiment of the present application, which provides a combined adapter for blowing out air based on the air bag, the second embodiment of the present application proposes another combined adapter for blowing down the air based on the wind bag. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0044] Concretely, the difference of the combined adapter for blowdown based on air bag provided in the second embodiment of the present application is that the combined adapter for blowdown based on wind bag also includes:

[0045] The connection assembly 3 is set on the outer surface of the outer wire joint 1, the connection assembly 3 includes a limit card slot 31, and the bottom of the inner wall of the limit card slot 31 is fixedly connected with a limit card plate 32 , the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com