Annular electrothermal film capable of avoiding film burning

An electric heating film and ring-shaped technology, applied in the direction of electric heating devices, ohmic resistance heating, ohmic resistance heating parts, etc., can solve the problems of film layer power attenuation, poor contact, money and material waste, etc., to reduce material waste and money loss , Good and stable contact, not easy to burn the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention will be described below in conjunction with the accompanying drawings and related embodiments. The embodiments of the present invention are not limited to the following embodiments, and the present invention relates to relevant necessary components in the technical field, which are regarded as well-known in the technical field Technology is known and mastered by those skilled in the art.

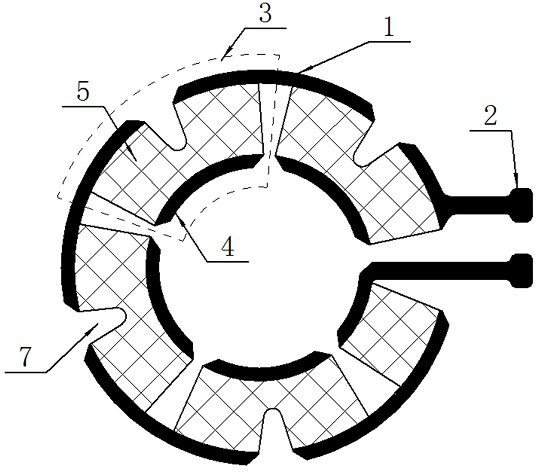

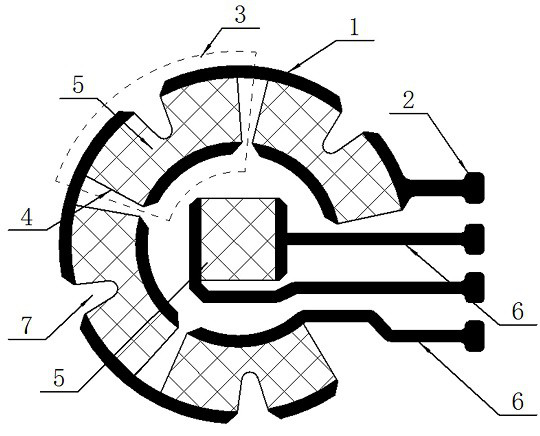

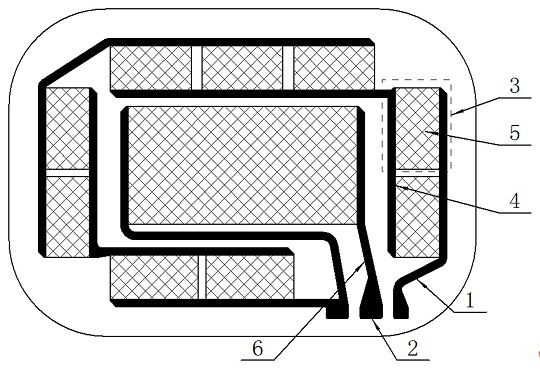

[0019] combine Figure 1 to Figure 3 As shown, a ring-shaped electric heating film that can avoid film burning is provided with a main electrode 1 that tends to be ring-shaped and is open, and a wire welding point 2 connected to the beginning and end of the main electrode 1. The main electrode 1 Several sections of heating regions 3 are connected in series, and the heating regions 3 are composed of sub-electrodes 4 connected in parallel to the main electrodes 1 and electrothermal films 5 connected between the main electrodes 1 and sub-electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com