Direct-acting oxygen production valve

A direct-acting, intake valve technology, applied in oxygen preparation, oxygen/ozone/oxide/hydroxide, inorganic chemistry, etc., can solve the problems of unable to adjust the pressure demand of the oxygen machine, lack of convenience, etc. Achieve the effects of good oxygen production capacity, good airtightness, and smooth air intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

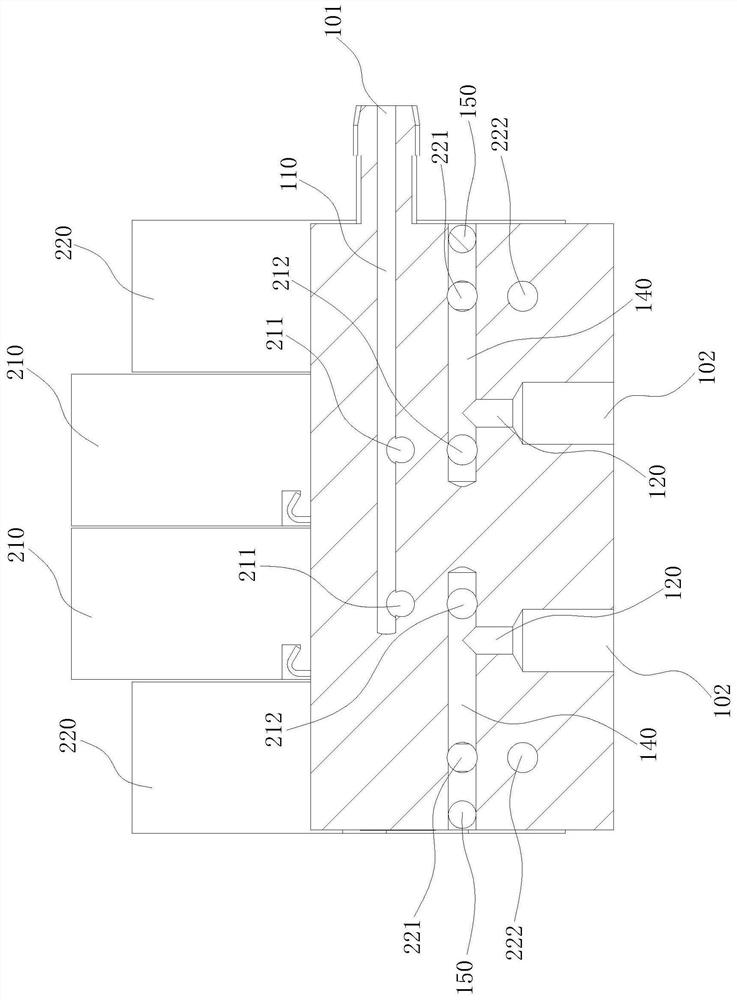

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical method of the present invention is further described, but the present invention is not limited to these embodiments.

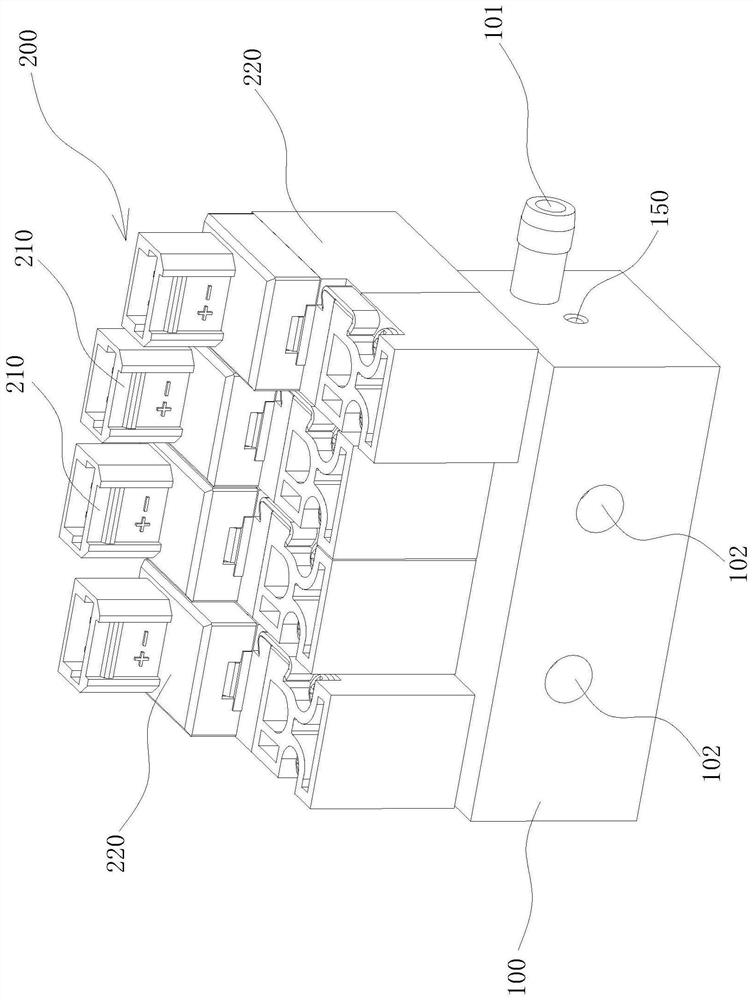

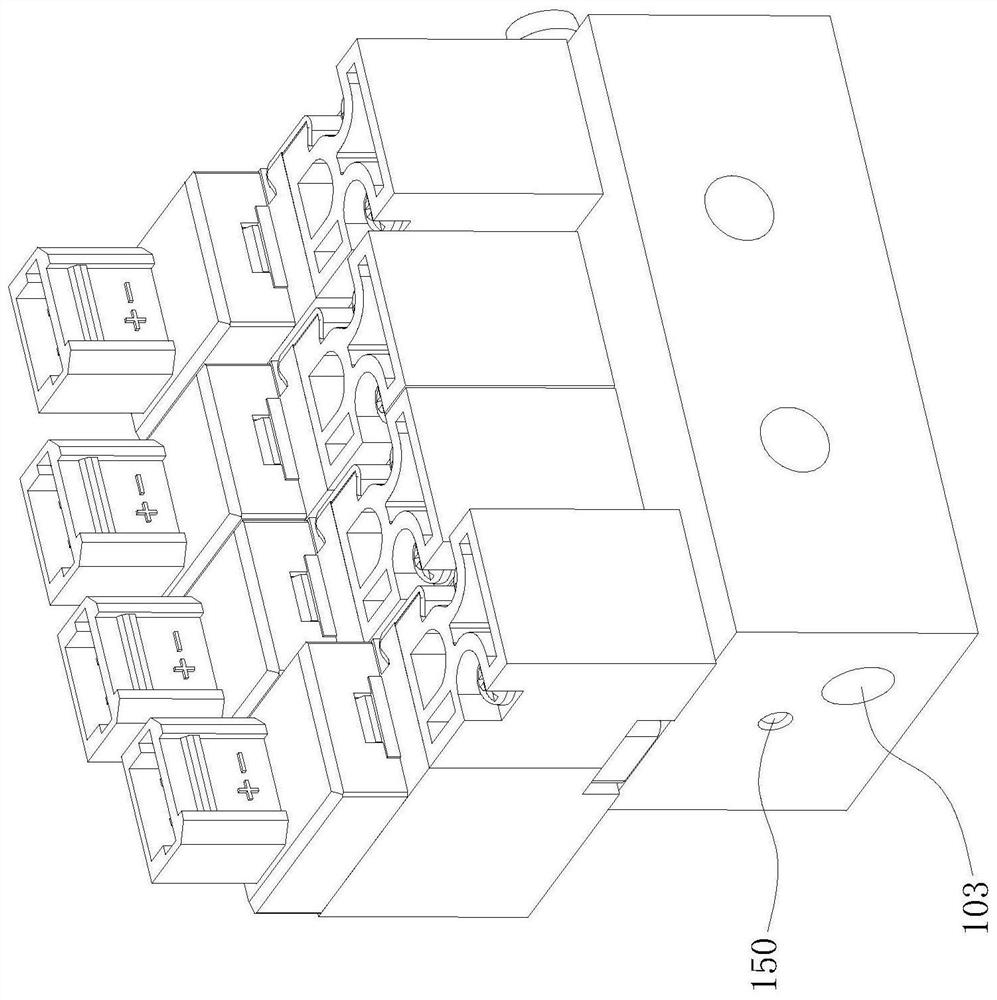

[0029] Such as Figure 1-5 As shown, the present invention provides a direct-acting oxygen generator valve, comprising:

[0030] Manifold 100, it is provided with inlet passage 110, outlet passage 120, exhaust passage 130 and connecting passage 140, and inlet passage 110 is connected with the external compressor (not shown in the figure), and outlet passage 120 is connected with the external compressor. The oxygen generator molecular sieve (not shown in the figure) is connected, and the compressor sends the gas inwardly from the intake passage 110 and outputs it to the oxygen generator molecular sieve outward, while the gas in the manifold 100 can pass through the exhaust passage 130 Exhaust outward.

[0031] There is at lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com