Ultrasonic-assisted high-pressure water jet mixed abrasive sprayer and heading machine

A high-pressure water jet and ultrasonic technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of low impact speed and low efficiency, and achieve the effects of reducing difficulty, facilitating maintenance, and facilitating wire access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

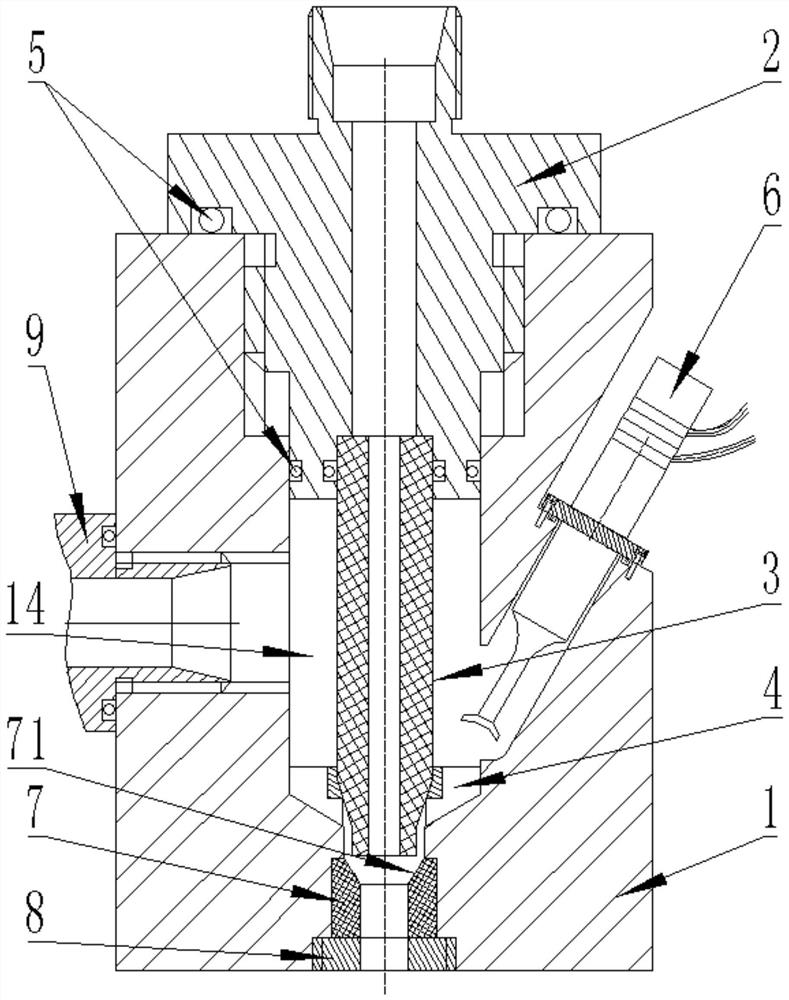

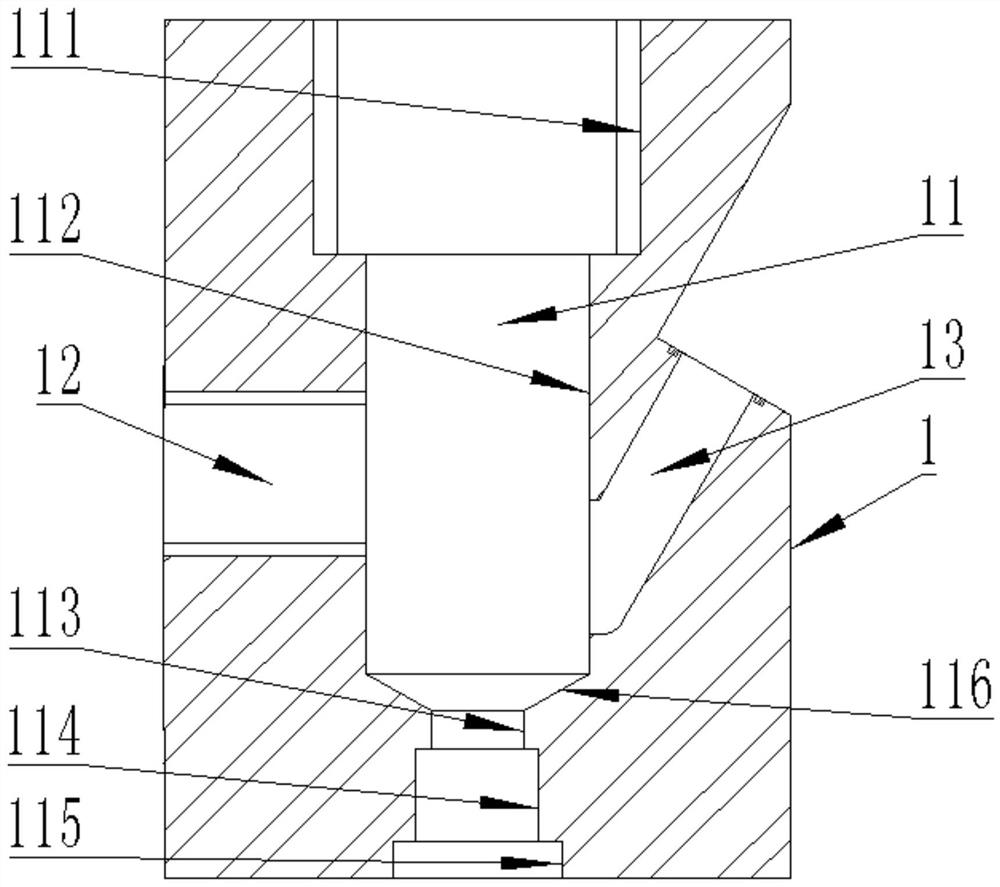

[0038] An ultrasonic-assisted high-pressure water jet mixed abrasive spray head, comprising an outer shell 1 and an ultrasonic vibrator 6, the outer shell 1 contains a main channel 11 and a side channel 12, the main channel 11 runs through the outer shell 1, and one end of the main channel 11 is a first The medium inlet, the other end of the main channel 11 is a mixing outlet, the outside of the outer casing 1 communicates with the main channel 11 through the side channel 12, the ultrasonic vibrator 6 can emit ultrasonic waves into the main channel 11, and the emission direction of the ultrasonic vibrator 6 faces the main channel 11. The other end of channel 11, such as figure 1 shown.

[0039] In this embodiment, the main channel 11 is in an upright state, and the side channel 12 is in a horizontal state. The main channel 11 runs through the upper and lower ends of the outer shell 1. The upper end of the main channel 11 is the first medium inlet of the outer shell 1. The main...

Embodiment 2

[0067] This embodiment is a modification of Embodiment 1, and the main difference between this embodiment and Embodiment 1 is that

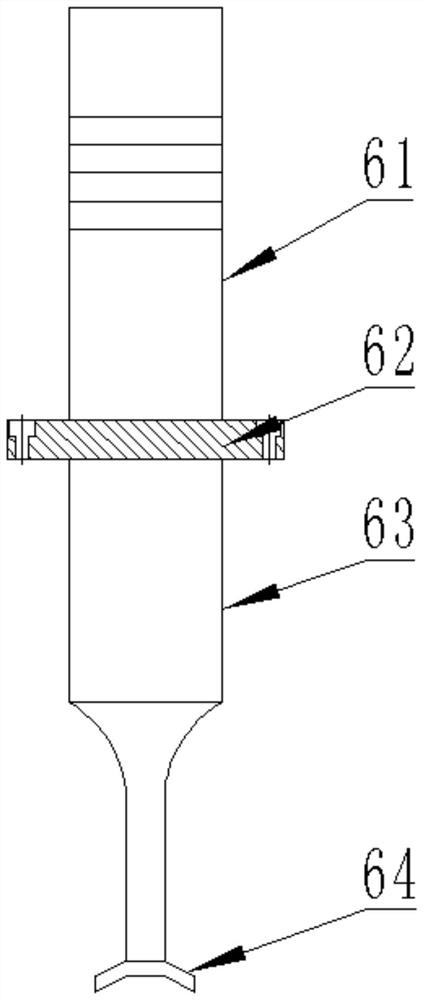

[0068] The ultrasonic-assisted high-pressure water jet mixed abrasive spray head includes a plurality of ultrasonic vibrators 6, and the plurality of ultrasonic vibrators 6 are located in the annular cavity 14, and the plurality of ultrasonic vibrators 6 are arranged at intervals along the circumferential direction of the annular cavity 14. 6 is connected and fixed to the abrasive material input wear-resistant nozzle pressure head 2. The ultrasonic vibrator 6 includes a piezoelectric ceramic transducer 61, a horn 63 and a water wave enhancement cover 64 connected in sequence. The cross section of the water wave enhancement cover 64 is arc-shaped. The arc-shaped opening faces the mixing outlet; along the axial direction of the outer casing 1, the ultrasonic vibrators 6 correspond to the communication gaps 43 one-to-one, and the side channel 12 is l...

Embodiment 3

[0082] This embodiment is a modification of Embodiment 1, and the main difference between this embodiment and Embodiment 1 is that

[0083] The abrasive material input wear-resistant nozzle head 2 and the abrasive material input wear-resistant nozzle 3 have an integral structure, and can become an integrated abrasive material input wear-resistant nozzle 3 . Abrasive input wear-resistant nozzle pressure head 2 and abrasive material input wear-resistant nozzle 3 are made of the same material, the inner diameter of abrasive material input wear-resistant nozzle pressure head 2 is the same as the inner diameter of abrasive input wear-resistant nozzle 3, and the abrasive nozzle positioning backing ring 4 can be omitted. A plurality of jet grooves 34 are arranged outside the outlet end of the abrasive input wear-resistant nozzle 3, and the plurality of jet grooves 34 are arranged at even intervals along the circumferential direction of the abrasive input wear-resistant nozzle 3, as ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap