Gas-liquid linkage device

A gas-liquid linkage and air return pipe technology, applied in safety devices, engine components, engine lubrication, etc., can solve the problems of inability to lubricate the joints of the drilling rig, poor atomization effect, etc., to achieve strong functionality, improve efficiency, expand The effect of the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

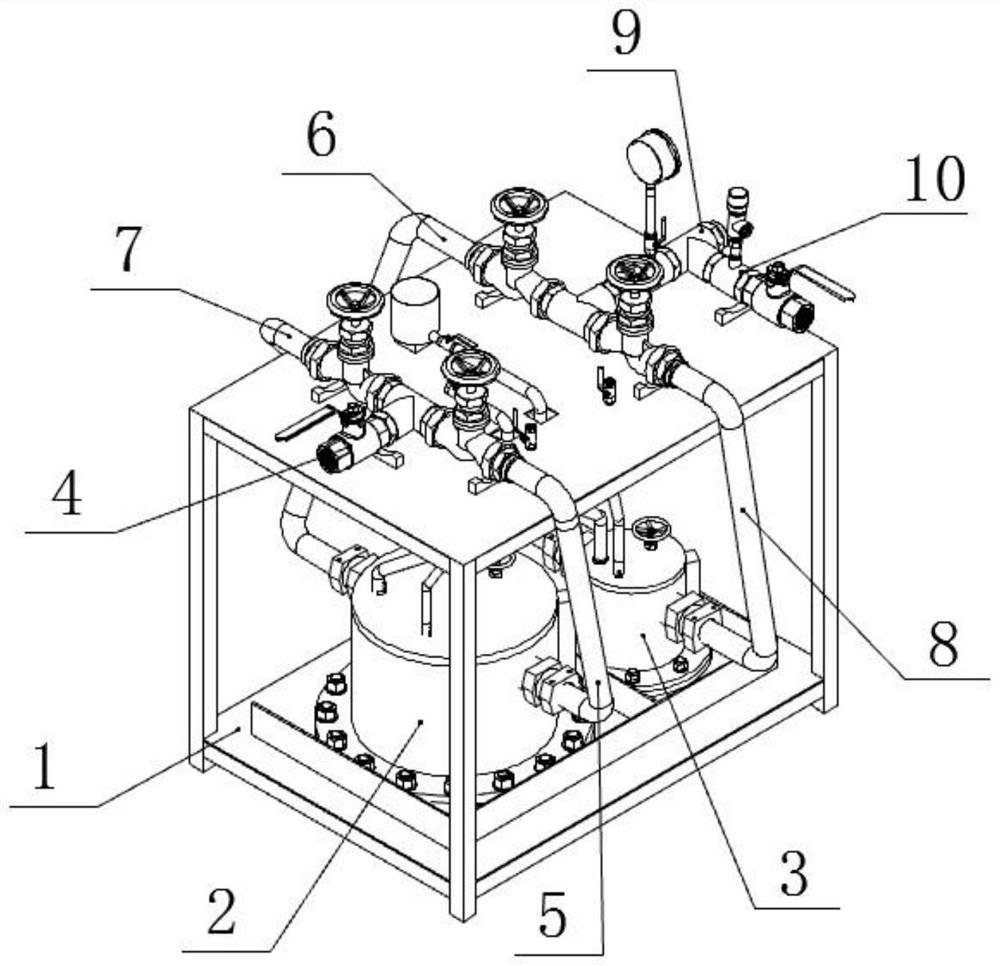

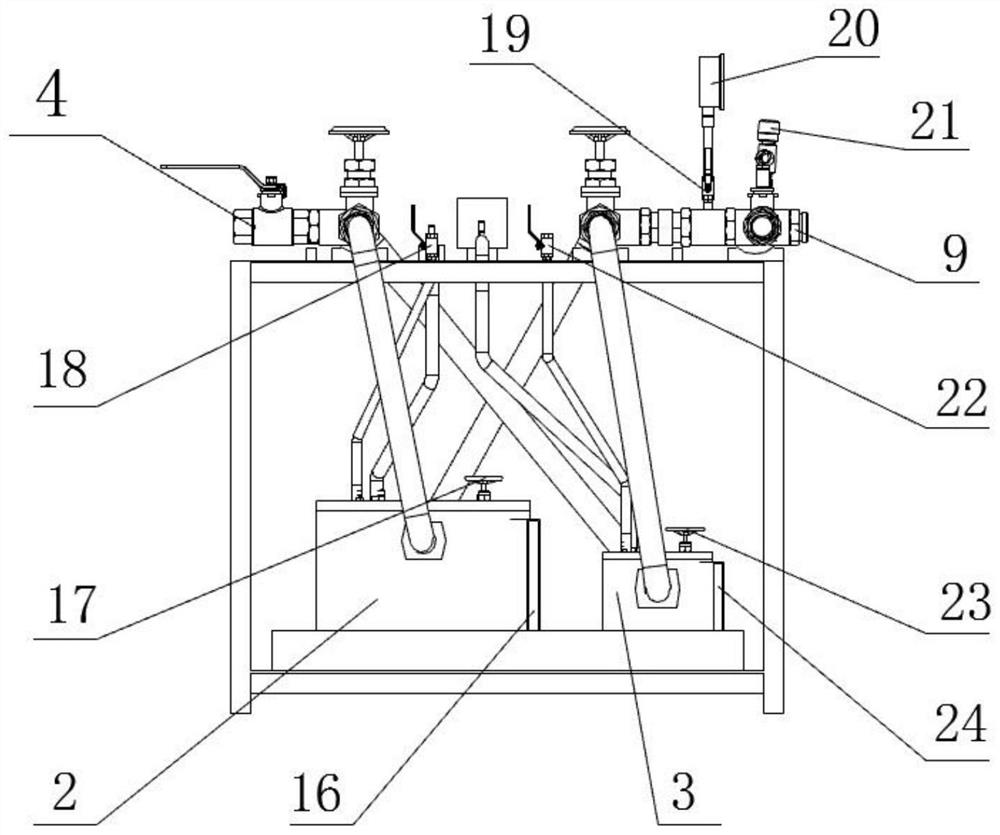

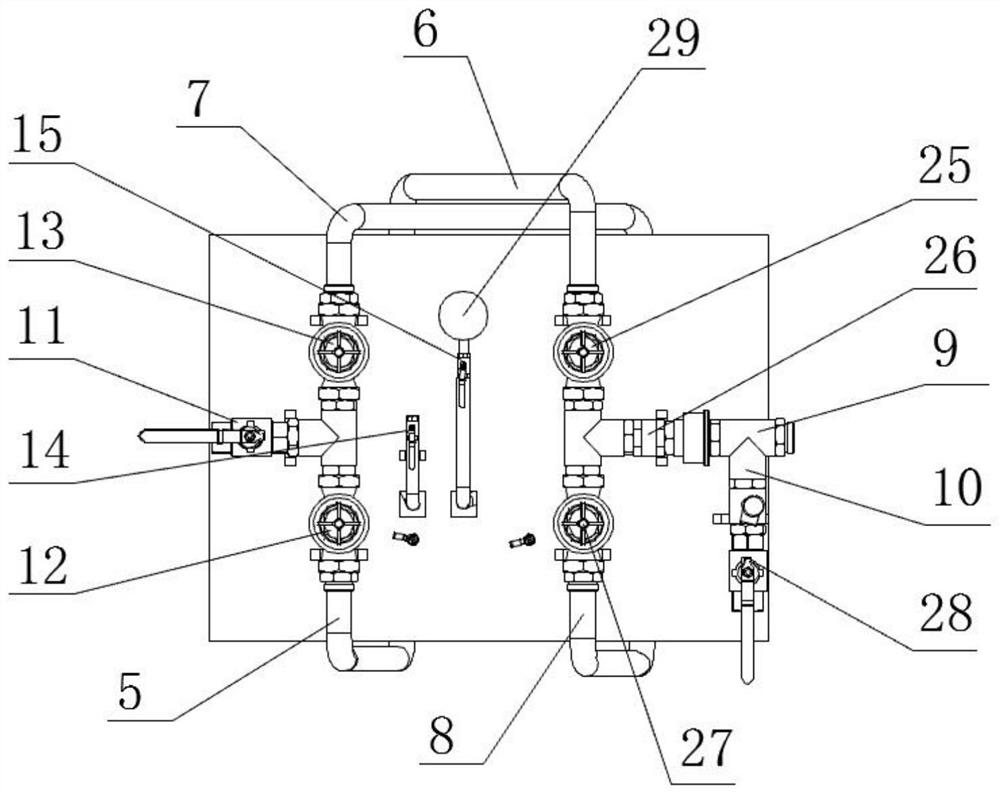

[0029] Such as Figure 1 to Figure 3 As shown, a gas-hydraulic linkage device includes a base frame 1, a total air intake pipe 4 and a total air outlet pipe 9. The base frame 1 includes an upper layer and a lower layer. The lower layer of the base frame 1 is connected with a water tank 2 and an oil tank 3 through bolts. The water tank 2 is connected with the water inlet pipe 5, the water return pipe 6, the water filling valve 14, the water level gauge 16, the water level regulating valve 17 and the water release valve 18, and the fuel tank 3 is connected with the oil inlet pipe 7, the oil return pipe 8, and the fuel tank 3. Valve 15, oil release valve 22, oil level regulating valve 23 and oil level gauge 24, the upper side of refueling valve 15 is connected with a refueling cup 29, the upper end of the water inlet pipe 5 and the upper end of the oil inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com