Anti-typhoon wind power generation equipment fixing base

A technology for wind power generation equipment and fixed bases, which is applied in the direction of wind power generation, installation/support of wind turbine configuration, etc., can solve problems such as broken brackets of wind power generation, uprooting of wind power generation equipment, etc. The typhoon effect is good and the effect of improving the stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

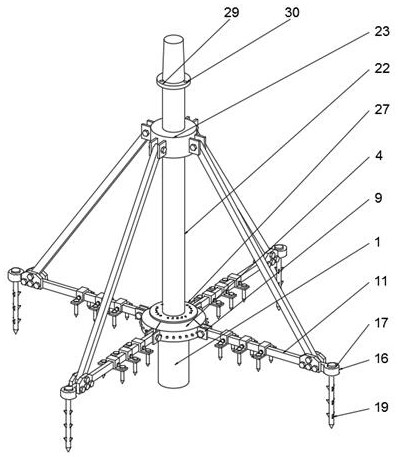

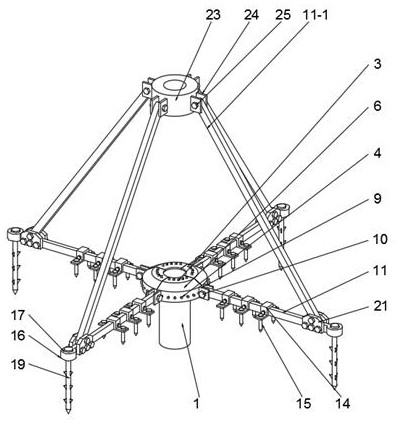

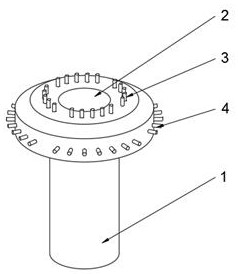

[0033] Refer to the attached Figure 1-8 , a fixed base for anti-typhoon wind power generation equipment, including a base main body 1, a strengthening mechanism, four support columns 11, a support rod 22 and a support ring 23, and a mounting hole 2 is opened on one side of the top outer wall of the base main body 1 for installation The inner wall of the bottom of the hole 2 is fixedly provided with a limit column 5, and the top side of the base body 1 is fixedly provided with the first thread positioning column 3 which is equidistantly distributed with the central axis of the mounting hole 2 as the center of the circle, and the side wall of the base body 1 The second thread positioning column 4 is fixedly arranged with the central axis of the mounting hole 2 as the center of the circle, and the reinforcement mechanism is covered with four base shells 6, and the top sides of the four base shells 6 are equidistantly distributed. The first fixing holes 7 of the four base shells ...

Embodiment 2

[0035]Based on the first embodiment, the reinforcement mechanism is covered on the outer wall of the base body 1, the four support columns 11 are located on the four sides of the reinforcement mechanism, the support rod 22 is located on the top of the base body 1, and the support ring 23 is located on the support rod 22 One side of the outer wall of the four supporting columns 11 is provided with three through holes 13 equidistantly distributed, and the top outer walls of the four supporting columns 11 are clamped with a reinforcing block 14 in a "bow"-shaped structure. The reinforcing block 14 The inner walls on both sides of the inner wall pass through the inner wall of the through hole 13 through the fixing rods, the bottom two ends of the reinforcement block 14 have sockets, the inner walls of the sockets are provided with reinforcement piles 15, and one end of the four support columns 11 is fixedly provided with a positioning block 16, positioning One end of piece 16 tops ...

Embodiment 3

[0037] On the basis of Embodiment 1, the outer walls of the two sides of the four base shells 6 are fixed with a first fixed piece 9, and one side of the first fixed piece 9 is provided with a first movable opening 10, and one end of the four support columns 11 The outer wall is provided with a second movable opening 12, and one side of the outer wall of the support column 11 passes through the second movable opening 12 and the inner wall of the first movable opening 10 through a rotating rod and is movably connected with the reinforcing mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com