Corpse incineration system

A corpse and cremator technology, applied in the field of corpse incineration systems, can solve the problems of inconvenience in cleaning the inner wall of the cremator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following is attached Figure 1-11 The application is described in further detail.

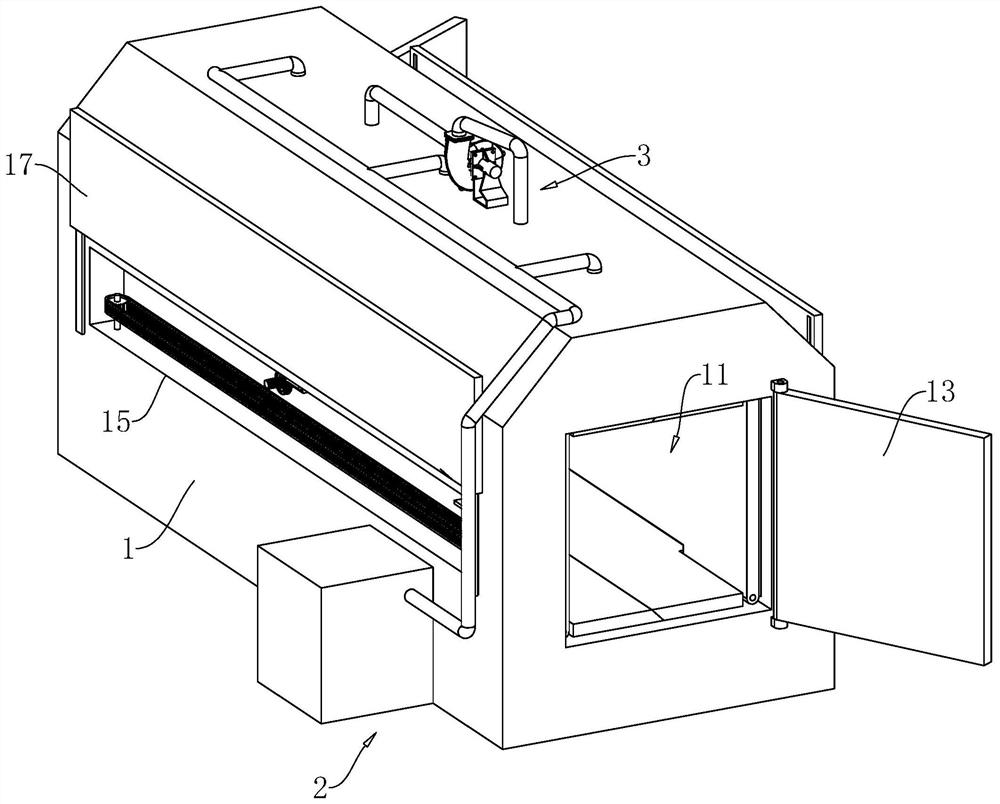

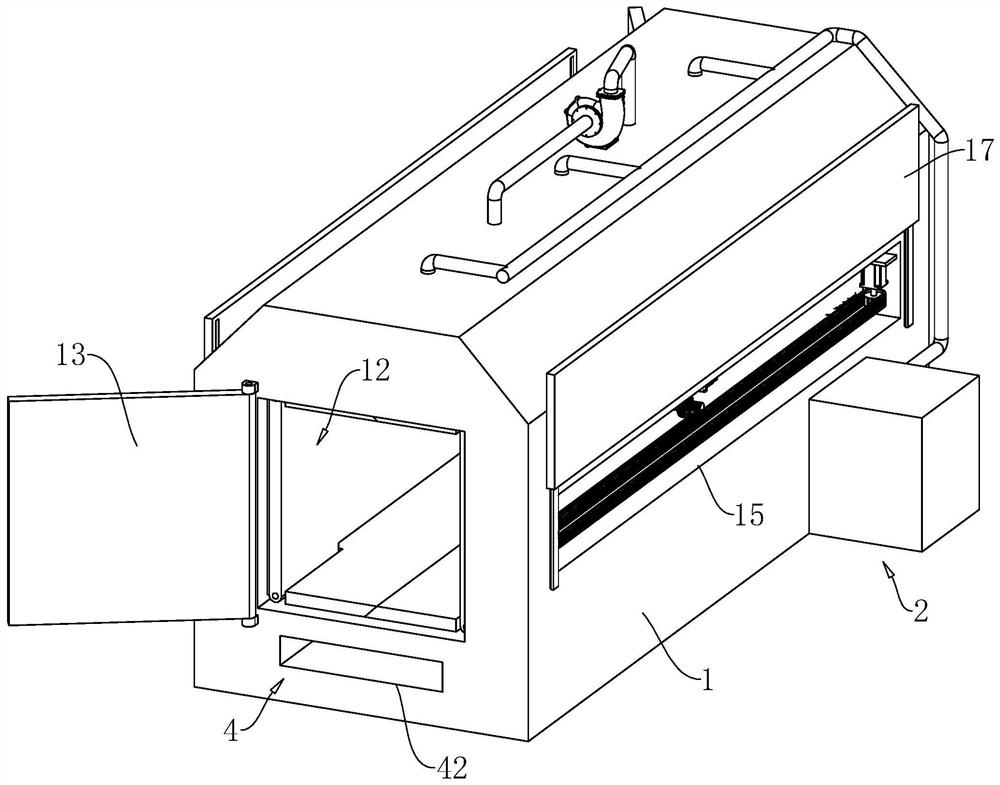

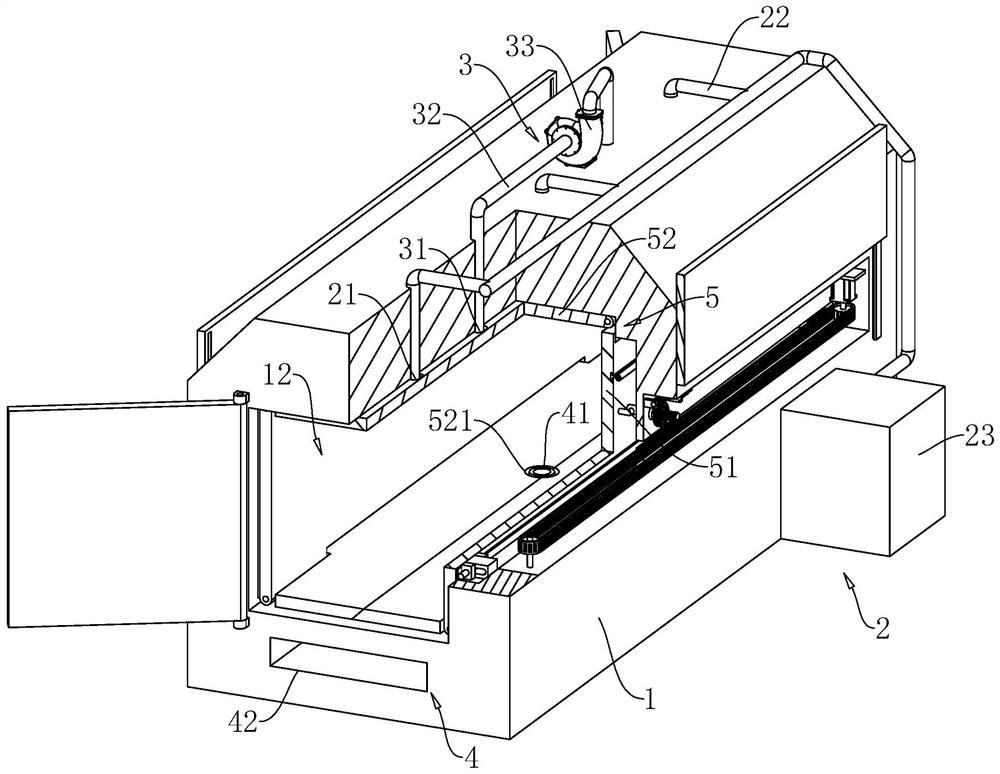

[0043] The embodiment of the present application discloses a corpse incineration system. refer to figure 1 with figure 2 , The incineration system includes a cremation furnace 1 , a combustion module 2 , an air supply module 3 and a smoke exhaust module 4 .

[0044] refer to figure 1 with image 3 One end of the cremation furnace 1 is provided with an entrance 11, and the body is sent into the cremation furnace 1 through the entrance 11. The combustion module 2 includes an oil tank 23 located on one side of the cremation furnace 1 for storing fuel oil. The inner top wall of the cremation furnace 1 is provided with a flame nozzle 21, and an oil pipe 22 is connected between the flame nozzle 21 and the oil tank 23. The fire head 21 is ejected and forms a flame to cremate the remains.

[0045] refer to image 3 , the air supply module 3 includes a blower 33 located on one side ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap