Novel induction motor rotor

An induction motor and rotor technology, applied in asynchronous induction motors, electromechanical devices, electrical components, etc., can solve the problems of uneven axial distribution of the magnetic field, affecting the mechanical strength of the rotor, large torsional torque, etc., to eliminate torsional and axial forces , reduce vibration and noise, reduce the effect of radial electromagnetic force waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

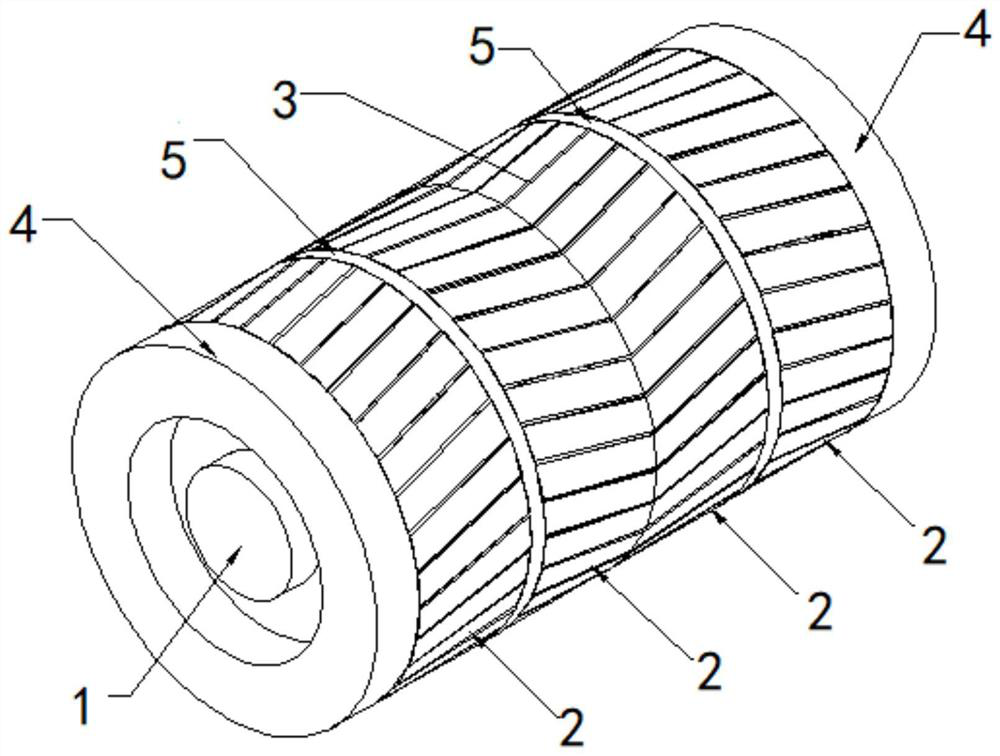

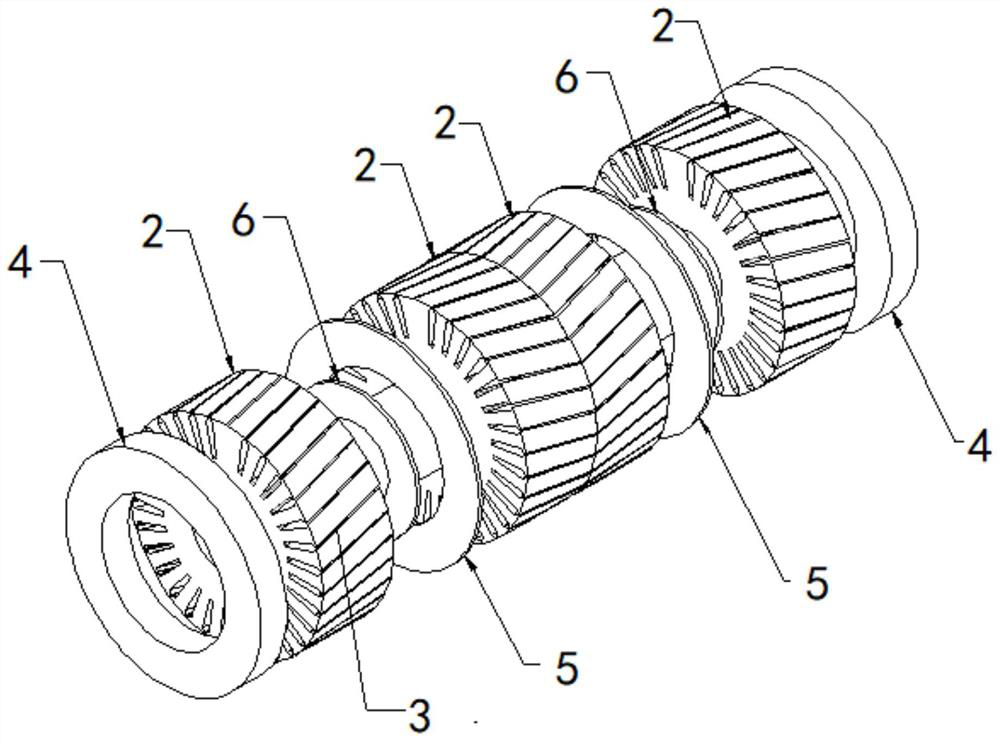

[0022] In order to reduce electromagnetic vibration and noise, according to figure 1 , figure 2 As shown, the present invention provides a new type of induction motor rotor, including: a motor shaft 1 and four rotors 2 that are sleeved on the motor shaft 1 and connected in sequence, and the inclined slots opened on the adjacent rotors 2 3. The directions are opposite, and their opposite endpoints coincide;

[0023] More specifically, there are squirrel cage guide bars inside the inclined groove 3 on the rotor 2 .

[0024] In a specific technical solution, the skewed slots 3 on the rotor 2 are evenly distributed along its axial direction. And preferably, the incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com