Cutter clamping cutter for part machining

A technology for clamping tools and parts processing, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of easily damaged tools, increased space for storage and inventory, and reduced durability of clamping jaws, so as to protect the tools. , The effect of increasing exhaust resistance and buffering impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

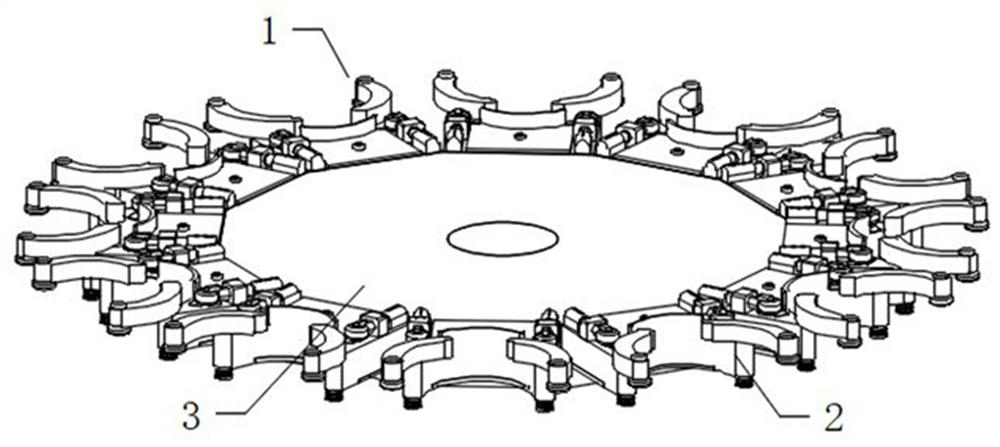

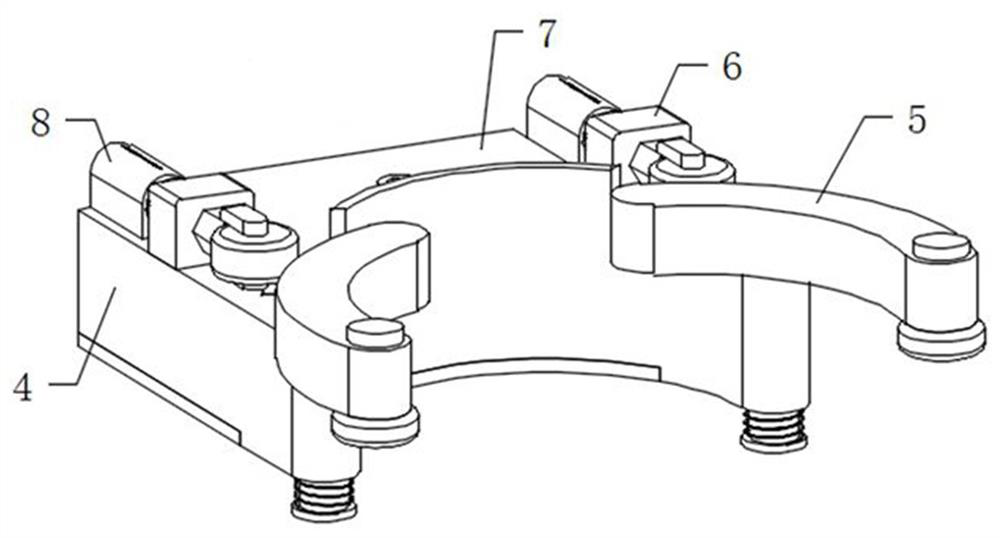

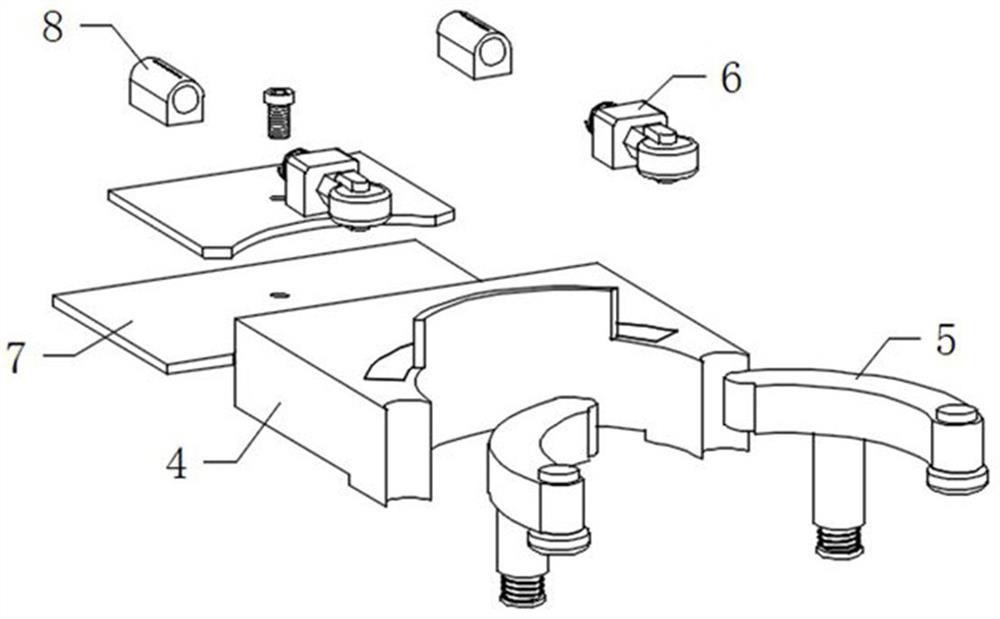

[0028] Example: such as Figures 1 to 8 As shown, a tool clamping tool for part processing includes a tool storage tray structure 1, the tool storage tray structure 1 includes a disc body 3, and a plurality of grippers 2 are fixedly connected to the outer side of the disc body 3. The two grippers 2 are evenly distributed on the outer side of the disc body 3, and the grippers 2 include a fixed seat 4, one end of the fixed seat 4 is rotatably connected with two fingers 5, and the upper surface of the fixed seat 4 is fixedly connected with a The deceleration main body 8, the buffer main body 6 is connected to the output end of the deceleration main body 8, the buffer main body 6 is movably connected with the clamp finger 5, the fixed seat 4 includes a fixed block 10, and the fixed block 10 is fixedly connected with the disc body 3 , the fixing block 10 is connected with the installation main body 7 , the fixing block 10 is fixedly connected with the blocking piece 9 , and the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com