Hoop fastening device and method

A technology of fastening devices and clamps, which is applied in the direction of hand-held tools and manufacturing tools, can solve problems such as difficult cable fastening, and achieve the effects of increasing size, extending distance, and extending mileage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

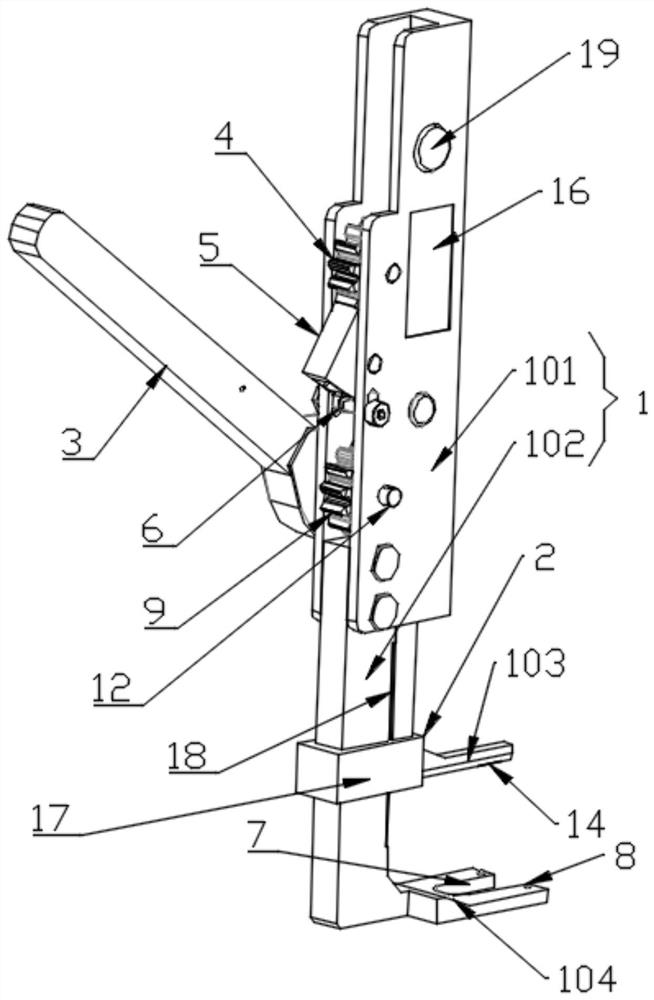

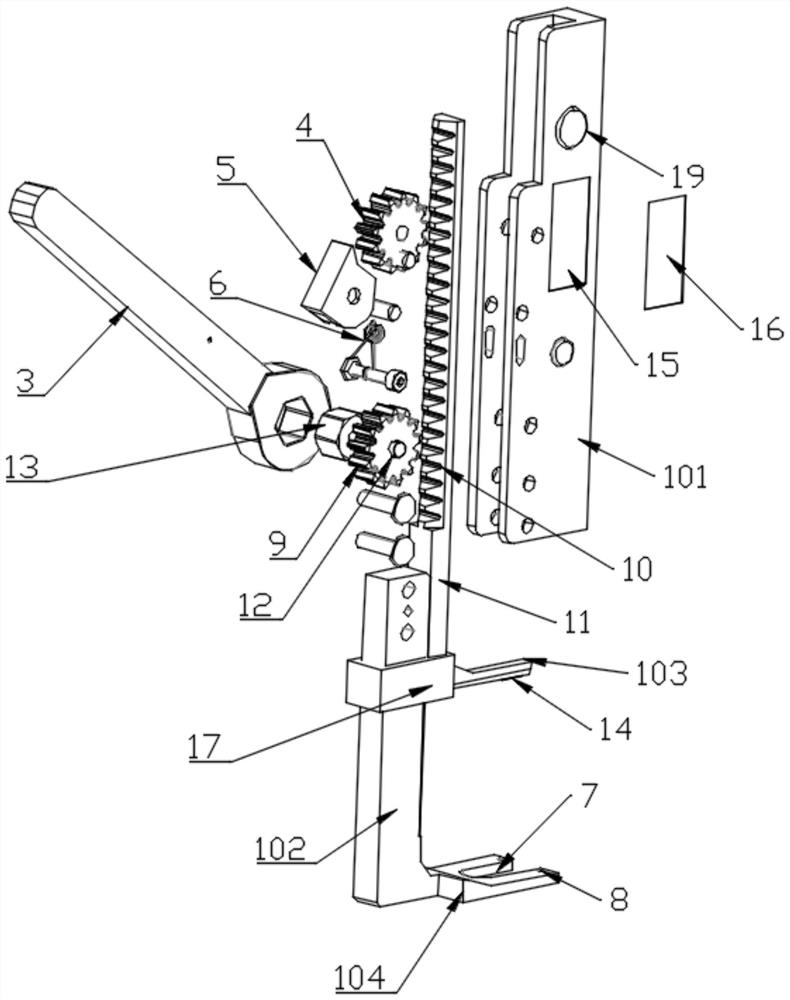

[0042] refer to Figure 1 to Figure 5, the present application discloses a clamp fastening device, including a bracket 1, the bracket 1 includes a housing 101 and a fixing pliers 102, the cross section of the housing 101 is a U-shaped structure, and the fixing pliers 102 are L-shaped structure, its top end is inserted into the housing 101, and is fixedly connected with the housing 101 by bolts, and its bottom is a lower chuck vertically connected to it;

[0043] The fastening device also includes a closing pliers 2, the two ends of the closing pliers 2 are respectively integrally connected with an upper chuck 103 and a connecting sleeve 17, the connecting sleeve 17 is a ring structure, and the sliding sleeve is placed on the fixed pliers 102, and The cross-section of the fixed clamp 102 is preferably square or rectangular, so as to avoid the rotation of the closed clamp 2, ensure that the upper clamp 103 and the lower clamp are always in a position facing each other, and impro...

Embodiment approach 2

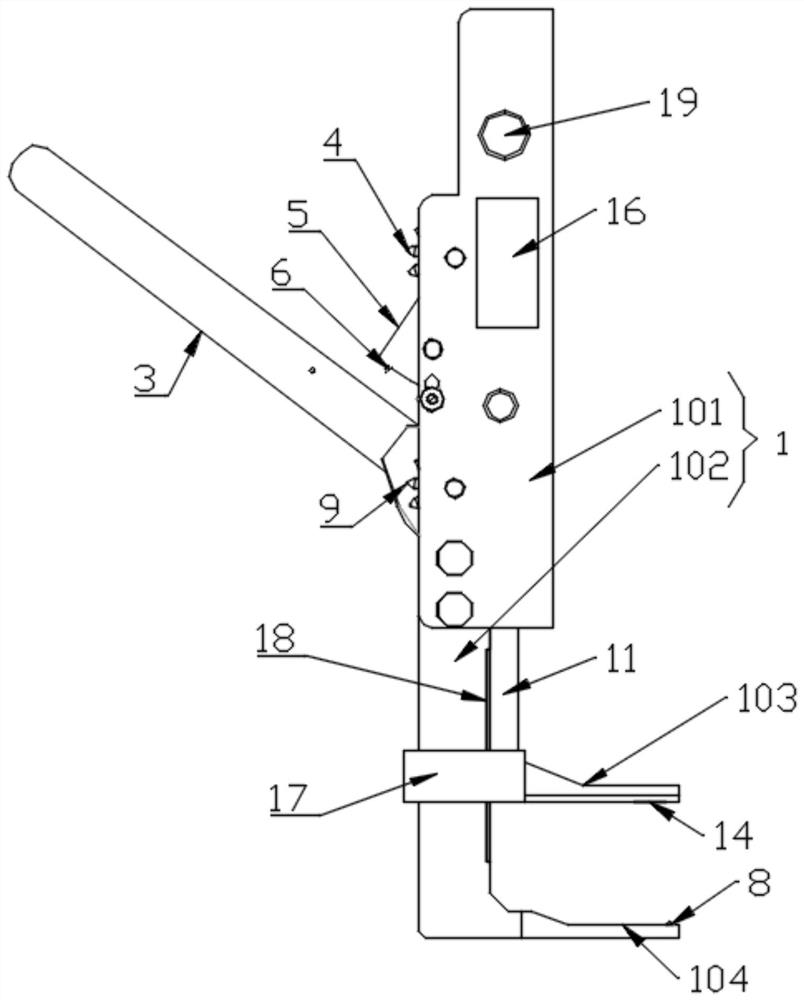

[0054] refer to Figure 1 to Figure 5 , this embodiment is an optional embodiment of the present invention, which discloses a clamp fastening device on the basis of Embodiment 1, including a bracket 1, and the bracket 1 includes a fixedly connected housing 101 and a fixed clamp 102, the housing 101 has a U-shaped cross-section, and a PCB control board 15 is fixedly arranged in its side wall, and at the same time, a display screen 16 connected to the PCB control board 15 is also provided on the surface of the housing 101;

[0055] The fixed clamp 102 is also provided with a distance sensor 18 connected to the PCB control board 15. The distance sensor 18 is preferably a capacitive ranging sensor, which has small size, simple structure, high resolution and accuracy, fast measurement speed, and high performance. Low power consumption, low cost, and low requirements for the use environment; it is fixedly arranged on the back or side of the fixed pliers 102, and at the same time, wh...

Embodiment approach 3

[0061] refer to Image 6 , this embodiment is another optional embodiment of the present invention, which discloses a fastening method based on the clamp fastening device described in Embodiment 1, including the following steps:

[0062] S1. Place the open end of the clamp to be fastened directly under the closing pliers;

[0063] First lay the cable and the clamp to be installed, and then insert the end of the fastening device provided with the closing clamp and the fixed clamp into the installation station of the clamp to be installed, and at the same time snap into the bottom hole of the structure on the installation station In the installation groove, the connecting ear plate on the lower side of the opening end of the clamp to be installed is placed on the lower chuck, and it is limited by the limit bump; the upper chuck is snapped into the upper connecting ear plate The connection with the clamp body to be installed, so as to realize the connection between the clamp to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com