Fixed mounting bracket of industrial robot

An industrial robot and mounting bracket technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as affecting the accuracy of industrial robot operations, cumbersome lubricating oil replacement process, and unstable rotation of the mounting seat, saving maintenance costs. , saving usage, avoiding the effect of unstable rotation or eccentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

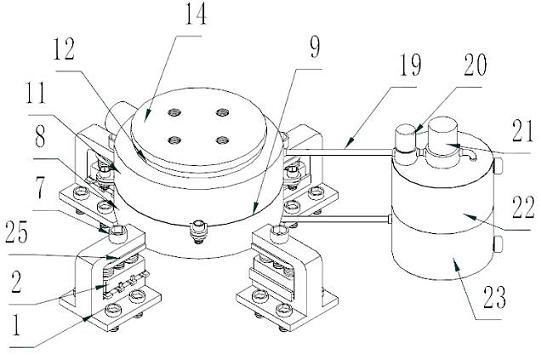

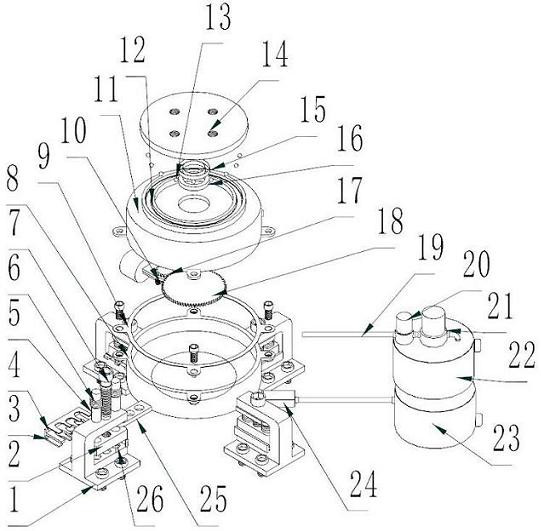

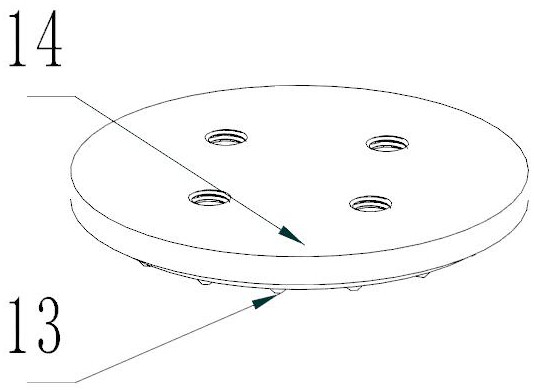

[0042] see Figure 1-6 , the invention discloses a fixed mounting bracket for an industrial robot, comprising a base and an industrial robot mounting base 14, the industrial robot mounting base is disc-shaped, horizontally arranged above the base and connected to the base There is a distance between them, the industrial robot mounting seat is provided with a coaxial vertically extending downward connecting shaft, the base is hollow, and a motor for driving the industrial robot mounting seat to rotate is provided in the inner cavity. , the connecting shaft extends into the cavity of the base from top to bottom and is connected with the motor shaft of the motor, and the connecting shaft and the top wall of the base are in rotation and sealing fit, the industrial An annular rolling guide rail is arranged between the robot mounting seat and the base.

[0043]The top surface of the industrial robot mounting base is preferably provided with a plurality of industrial robot mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com