Production process of high-temperature-resistant porous isolating membrane

A production process and isolation film technology, applied in the field of high temperature resistant perforated isolation film production process, can solve problems such as low work efficiency, reduced service life of the winding roller, and need to stop for replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

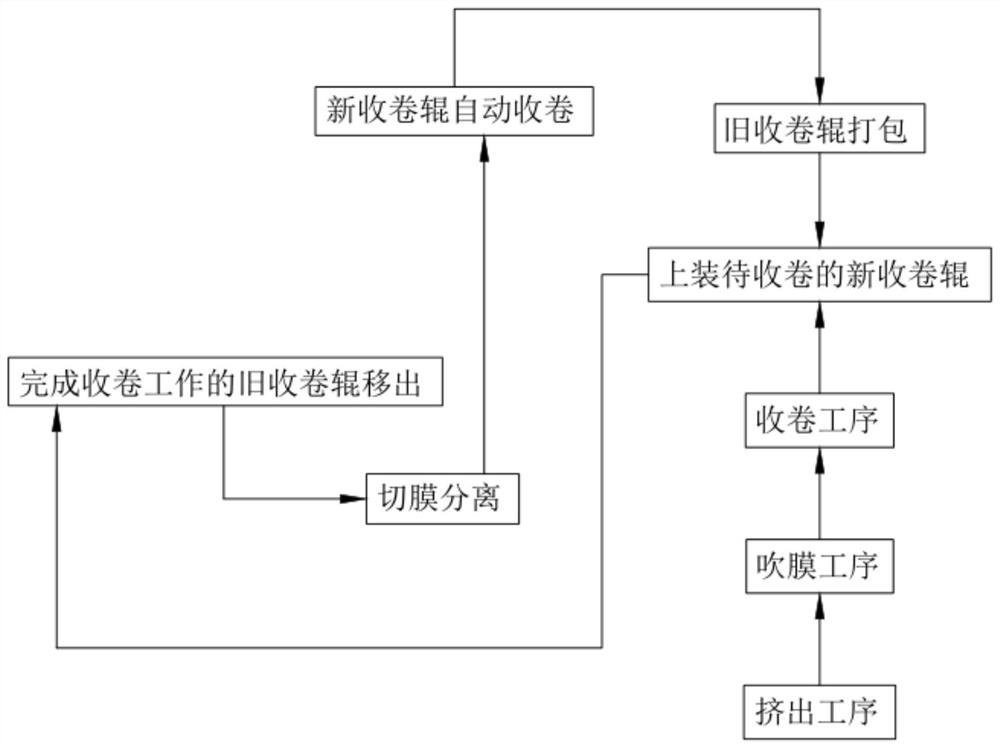

[0105] Such as figure 1 Shown, described a kind of production technology of high temperature resistant porous isolation film, comprises the following steps:

[0106] Step 1, the extrusion process, the extruder extrudes the high-temperature-resistant porous isolation film, and the high-temperature-resistant porous isolation film extruded in the extrusion process includes a three-layer structure arranged from top to bottom and the structure of each layer is the same, Any one layer contains antioxidant content ≤ 1%, synthetic agent content ≤ 1%, HDPE content ≥ 95% and high-territorial content ≥ 3%;

[0107] Step 2, film blowing process. The film blowing process is set at the output end of the extrusion process. The film blowing machine blows the high-temperature-resistant porous isolation film into a cylindrical shape, and flattens it for output after cooling;

[0108] Step 3, a winding process, the winding process is set at the output end of the film blowing process;

[0109] ...

Embodiment 2

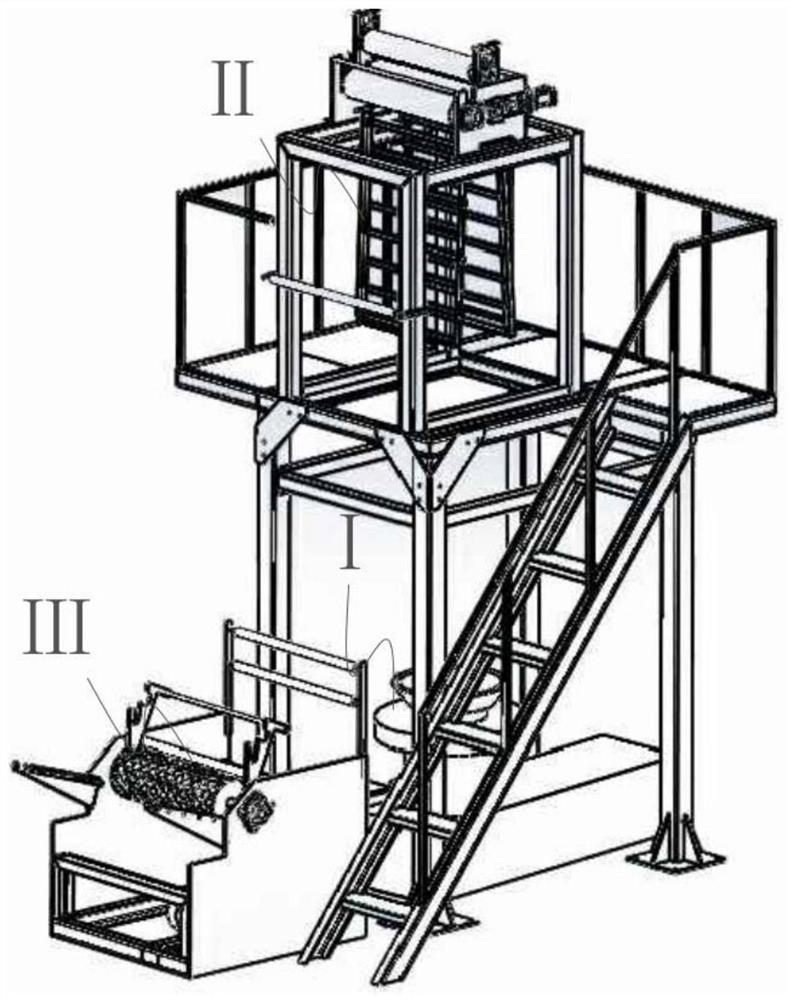

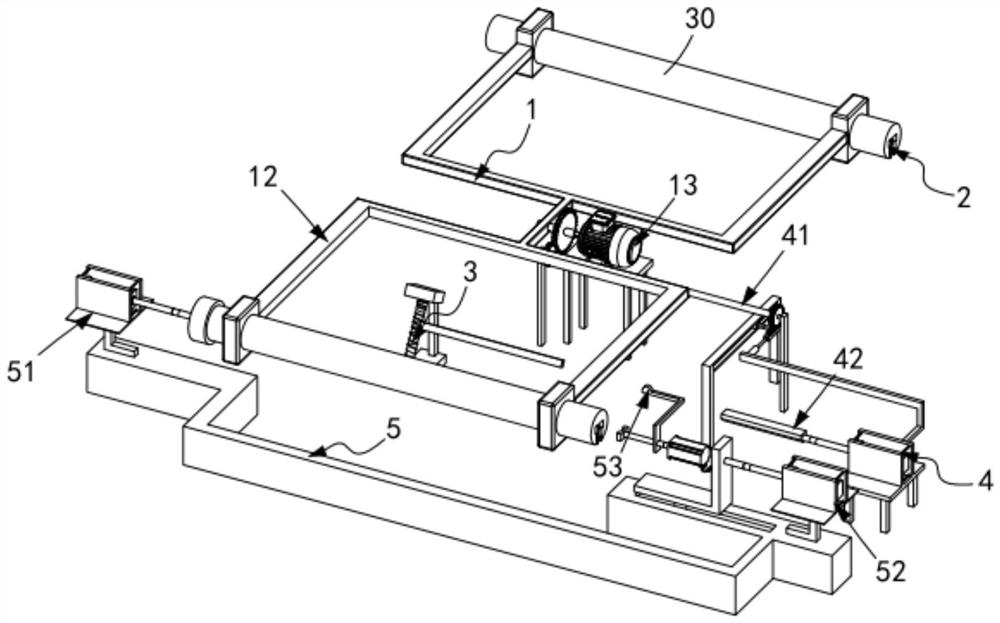

[0136] Such as Figure 4 , figure 2 and image 3 As shown, a high-temperature-resistant porous isolation film production system includes an extruder I, a film blowing machine II arranged on one side of the extruder, and a winder arranged on one side of the extruder I Ⅲ, the winder Ⅲ includes:

[0137] Switching mechanism 1, the switching mechanism 1 includes a translation assembly 12 and a first drive assembly 13 for driving the translation assembly 12 to rotate, one end of the translation assembly 12 is a winding station 10 and the other One end is the transmission station 20, the winding roller 30 is rotatably arranged on the translational assembly 12 and the compensating assembly 2 is arranged in it, and the lower end of the winding roller 30 is provided with a fastening groove 2a;

[0138] A pressing mechanism 3, the pressing mechanism 3 is located above the winding station 10;

[0139] The cutter mechanism 4, which is located between the winding station 10 and the tr...

Embodiment 3

[0182] Such as Figure 15 , Figure 16 , Figure 18 and Figure 21 As shown, the parts that are the same as or corresponding to those in the second embodiment are marked with the corresponding reference numerals in the second embodiment. For the sake of simplicity, only the differences from the second embodiment will be described below. The difference between this embodiment three and embodiment two is:

[0183] further, such as Figure 16 to Figure 15 As shown, the second drive assembly 52 includes a second flat-push cylinder 521 installed on the frame e520 with its telescopic end horizontally arranged, fixedly connected with the telescopic end of the second flat-push cylinder 521 and slidingly arranged at the lower end The motor frame 522 in the limit slot of the frame e520, the second drive motor 523 installed on the motor frame 522 and the plug block 524 arranged at the output end of the second drive motor 523, the plug block 524 is set There are chamfers and the cham...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com