Centrifugal separation cup and continuous separation method

A technology of centrifugal separation and centrifugal chamber, which is applied in the field of separation, can solve problems such as the difficulty of material particles, the lack of a method for continuous separation of material particles, and the destruction of the stability of the rotating fluid, so as to achieve optimized separation conditions, large centrifugal kinetic energy, and improved separation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

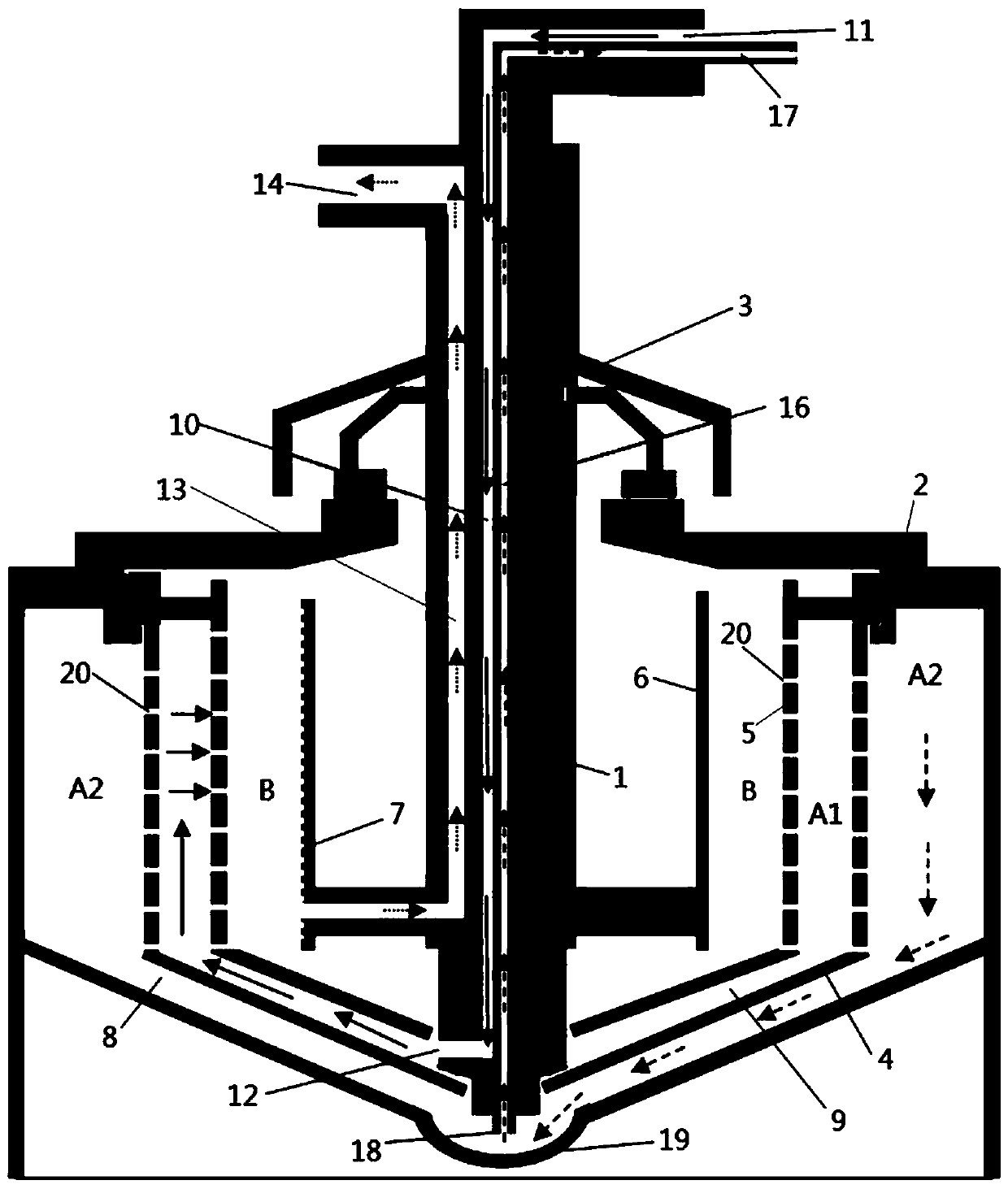

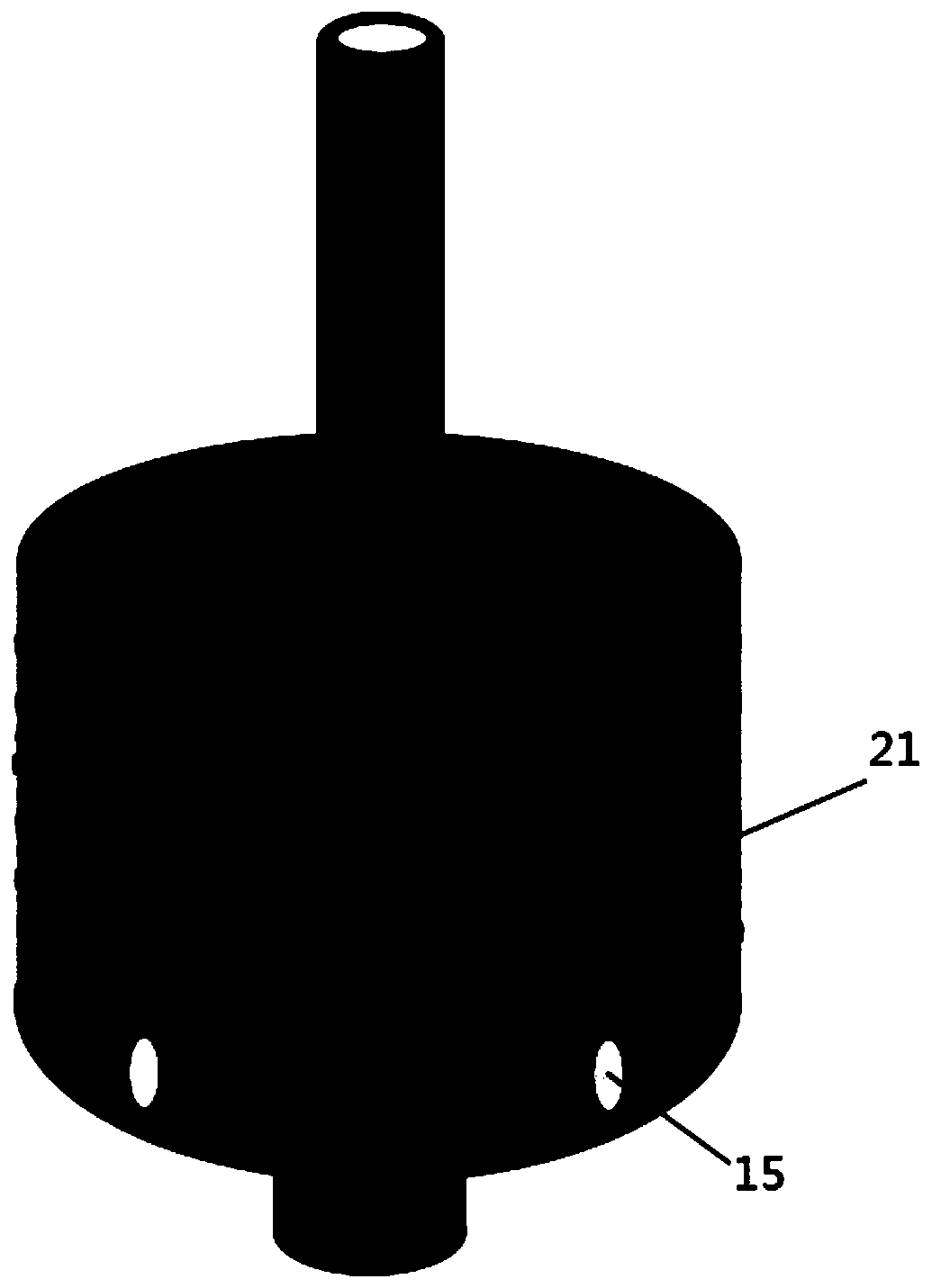

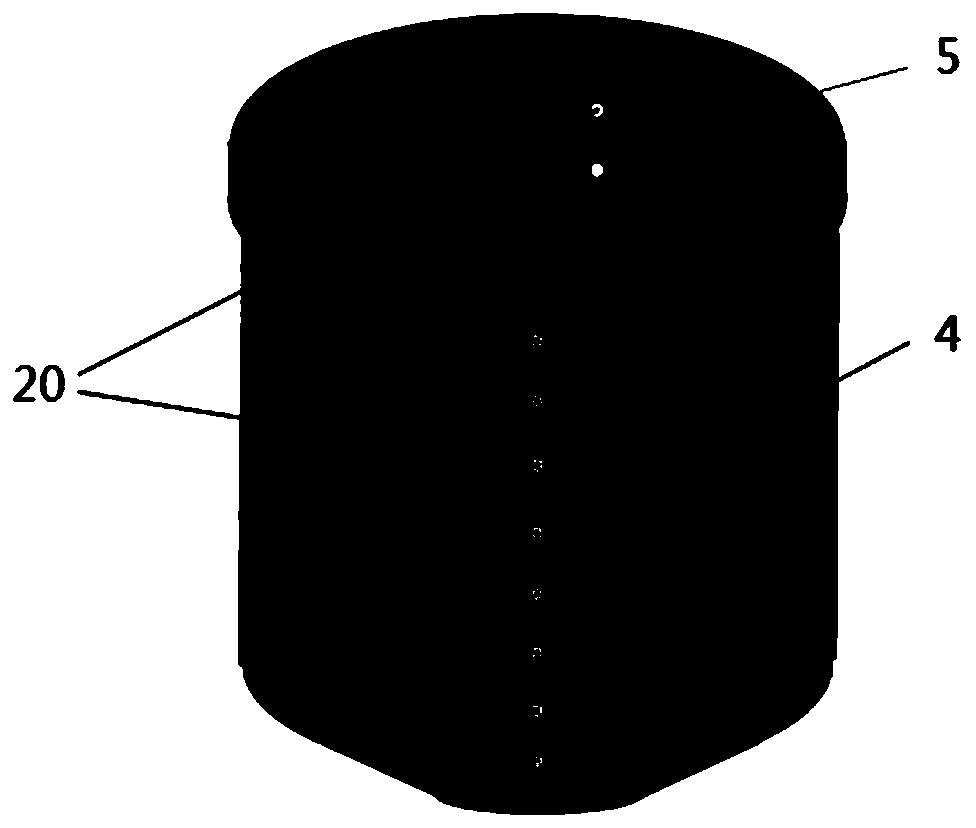

[0044] A centrifugal separation cup, comprising: a filter core tube, a centrifugal chamber, a fixed cover, a stabilizing sleeve and a flow guide sleeve.

[0045] The filter core tube is arranged inside the centrifuge cabin, the upper end is connected with the fixed cover, and the lower end is suspended in the cone bowl at the bottom of the centrifuge cabin. The filter core tube includes a filter bed and a core tube. A diversion groove is arranged on the filter bed, and a filter membrane is arranged outside the filter bed. The diversion grooves are collected into the filtrate inlet; the filtrate inlet is set at the lowest end of the filter bed.

[0046] The upper part of the centrifugal chamber is open, the middle part is cylindrical, the bottom is dish-shaped, and the center of the bottom is a bullet-shaped cone bowl; the bottom of the centrifugal chamber plays the role of gathering and separating the material particles. A stabilizing sleeve and a diversion sleeve are arrang...

example 2

[0060] In this example, a centrifuge cup is used for harvesting and washing cells during large-scale cell culture.

[0061] In this embodiment, the centrifuge cup is used to harvest and wash the cells, and a filter membrane with a pore size smaller than the cell diameter is used. The culture fluid line is connected to the liquid inlet, the waste liquid line is connected to the filtrate outlet, and the cells are harvested in the centrifuge chamber. After the liquid is fed in, switch the cleaning liquid pipeline to the liquid inlet for cell cleaning. After washing, the cells are collected through the concentrate outlet.

[0062] The pump provides positive pressure or / and negative pressure to form a pressure drop on both sides of the filter membrane as the driving force for the liquid flow in the centrifuge chamber. On the basis of considering the sensitivity of cells to centrifugal shear force, the relationship between centrifugal speed and filtration pressure was determined. ...

example 3

[0065] In this embodiment, a centrifuge cup is used for plasma separation.

[0066] Currently, the method of plasma collection is to use a centrifugal separation cup. In the existing separation cup structure, there is only a blood inlet and a plasma collection outlet, and there is no return path for blood cells. During the process of plasma collection, blood cells gradually gather in the separation cup, and the effective separation space of centrifugal separation is gradually occupied by cells, the separation effect becomes worse and worse, and finally loses the separation effect. At this time, the blood cells in the separation cup must be returned to After the infusion is emptied, the work of collecting plasma can be started again. Therefore, it collects plasma intermittently and does not have the function of continuous collection.

[0067] In this embodiment, a centrifuge cup is used for plasma separation. Connect the arterial line to the inlet, the venous line to the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com