One-time pouring system for U-shaped bottom plate of cable trench and construction method of one-time pouring system

A cable trench and U-shaped technology, which is applied to the one-time pouring system of the cable trench U-shaped bottom plate and its construction field, can solve problems such as impermeability, construction methods that cannot meet construction requirements, and difficulties, so as to improve stability and save production costs , Improve the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

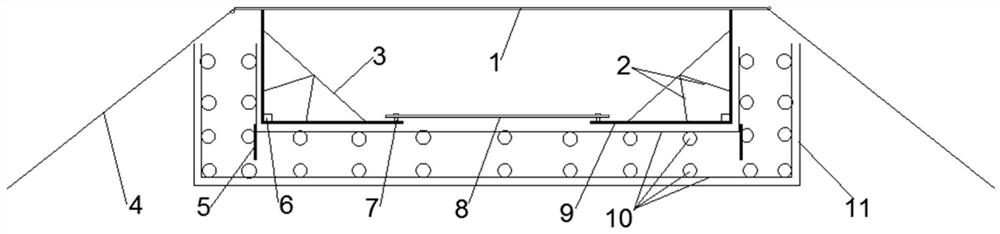

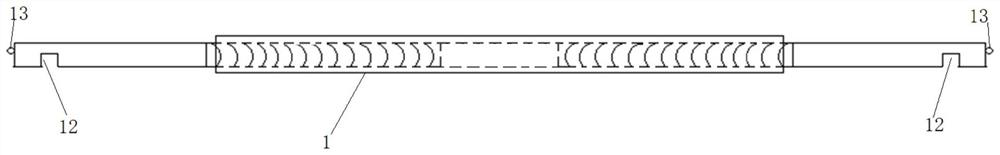

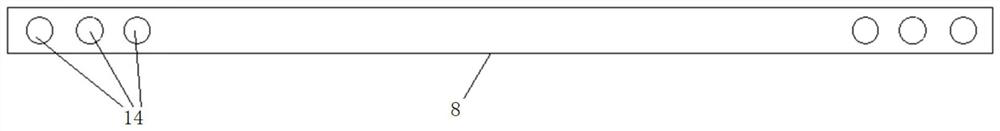

[0018] Such as Figure 1 to Figure 3 As shown, a cable trench U-shaped bottom plate one-time pouring system includes a U-shaped outer mold 11, a U-shaped steel mesh 10 laid in the U-shaped outer mold 11, and a bottom plate installed on the U-shaped steel mesh 10 at the junction of the side walls on both sides. The vertical wire mesh 5 at the place, the right-angled inner mold 9 that is matched at the yin corners on both sides of the U-shaped steel mesh 10, the U-shaped outer mold 11, the U-shaped steel mesh 10, the vertical steel wire mesh 5 and the right-angled inner mold 9 are all along the longitudinal direction. The length is set, there is an interval between the bottom edges of the inner mold 9 at right angles on both sides and is connected by the lower rod 8 along the line, and the top edge is connected by the upper rod 1 along the line, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com