A method and system for self-adaptive regulation and control of crystal growth power supply parameters

An adaptive regulation and crystal growth technology, applied in crystal growth, chemical instruments and methods, furnace control devices, etc., can solve problems such as low flexibility, increased sintering failure, and failure to consider temperature differences, etc., to improve flexibility and intelligent effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

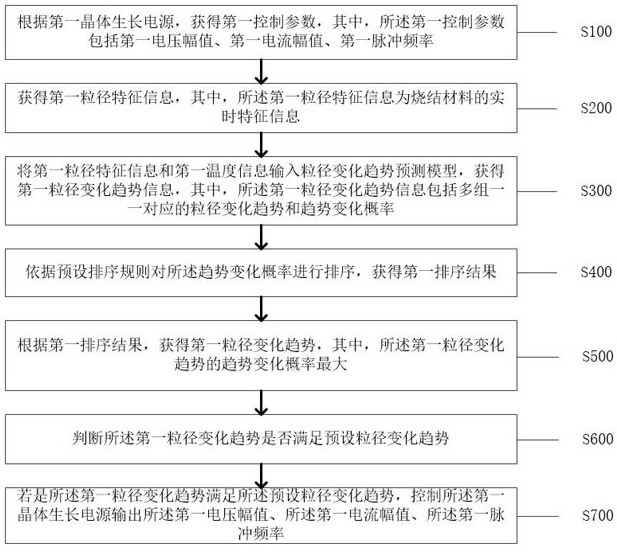

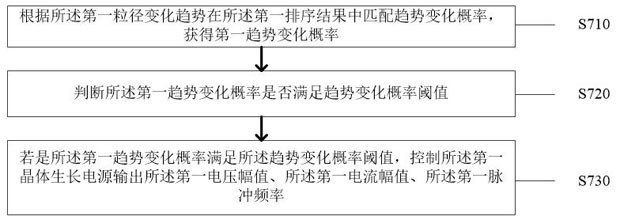

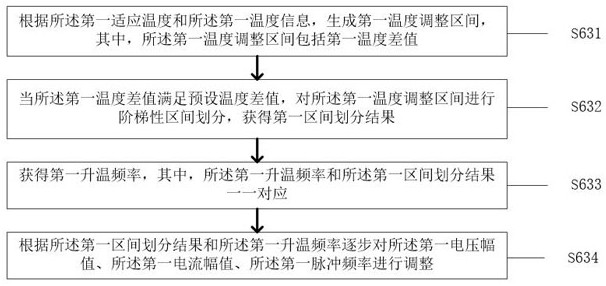

[0029] Such as figure 1 As shown, the embodiment of the present application provides an adaptive regulation method of crystal growth power supply parameters, the method is applied to an adaptive regulation system of crystal growth power supply parameters, and the method includes:

[0030] Step S100: Obtain first control parameters according to the first crystal growth power supply, wherein the first control parameters include a first voltage amplitude, a first current amplitude, and a first pulse frequency;

[0031] Specifically, the first crystal growth power supply is the control power supply of the crystal furnace for manufacturing crystals. Since the manufacture of crystals generally needs to control the parameters of the power supply, and the power supply is a device that provides power to the crystal furnace, it directly affects the work of the crystal furnace. Therefore, by obtaining the first voltage amplitude, the first current amplitude, and the first pulse frequency...

Embodiment 2

[0088] Based on the same inventive idea as an adaptive control method for crystal growth power parameters in the foregoing embodiments, the present invention also provides an adaptive control system for crystal growth power parameters, such as Figure 6 As shown, the system includes:

[0089] The first obtaining unit 11, the first obtaining unit 11 is used to obtain the first control parameter according to the first crystal growth power supply, wherein the first control parameter includes the first voltage amplitude, the first current amplitude, the first a pulse frequency;

[0090] A second obtaining unit 12, the second obtaining unit 12 is configured to obtain first particle size characteristic information, wherein the first particle size characteristic information is real-time characteristic information of the sintered material;

[0091] The first input unit 13, the first input unit 13 is used to input the first particle size feature information and the first temperature i...

Embodiment 3

[0125] Refer below Figure 7 An electronic device according to an embodiment of the present application will be described.

[0126] Figure 7 A schematic structural diagram of an electronic device according to an embodiment of the present application is shown.

[0127] Based on the inventive concept of an adaptive control method for crystal growth power supply parameters in the aforementioned examples, the present invention also provides an adaptive control system for crystal growth power supply parameters, on which a computer program is stored, and the program is executed by a processor When realizing the steps of any method of an adaptive control system for crystal growth power supply parameters described above.

[0128] Among them, in Figure 7 In, bus architecture (represented by bus 300), bus 300 may include any number of interconnected buses and bridges, bus 300 will include one or more processors represented by processor 302 and various types of memory represented by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com