Spiral dynamic reciprocating scanning optical system

An optical system and reciprocating scanning technology, which is applied in the field of laser scanning optical systems, can solve the problems of missed scanning, inability to completely cover the surface to be scanned, and non-coincident translation directions, so as to increase adaptability, avoid missing scanning problems, and improve scanning quality and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

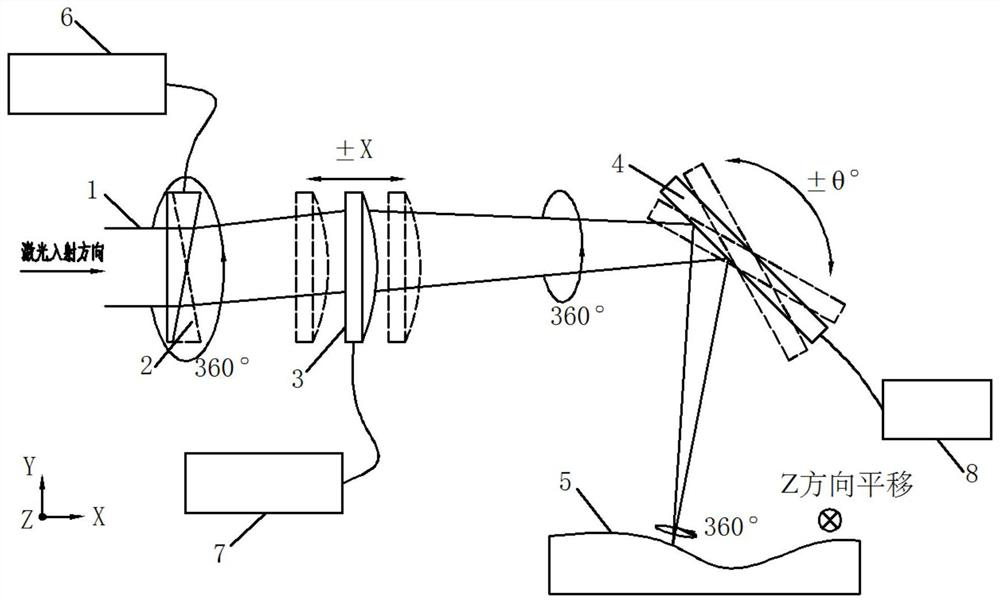

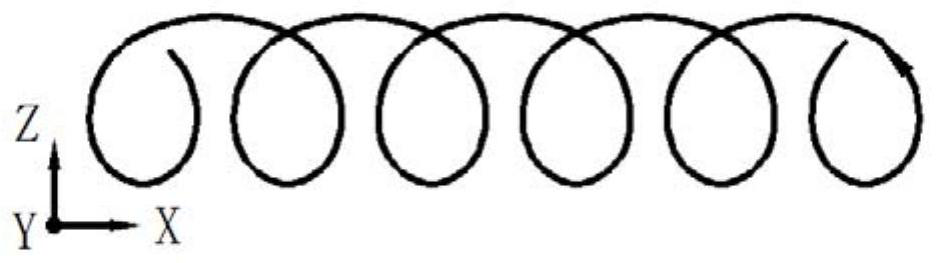

[0017] See figure 1 , a helical dynamic reciprocating scanning optical system, comprising a vibrating mirror scanning device and a workpiece 5 to be scanned, the vibrating mirror scanning device sequentially includes a deflecting prism 2, a dynamic focusing mirror 3, and a swinging vibrating mirror 4 according to the optical path , wherein, the deflection prism 2 is a prism whose one side is inclined to the optical axis and the other side is perpendicular to the optical axis, and the deflection prism 2 is controlled by a rotation controller 6 to rotate 360° uninterruptedly around its optical axis; The dynamic focusing mirror 3 is controlled by a reciprocating linear motion controller 7, and performs a reciprocating linear motion along the X-axis direction; the oscillating vibrating mirror 4 is controlled by a reciprocating swing controller 8, and performs a reciprocating swing motion in the X-Y plane around its central axis; The workpiece 5 makes a reciprocating linear motion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com