A high-precision automatic flash removal device and method for rubber sealing rings

A rubber sealing ring, high-precision technology, applied in household appliances, other household appliances, household components, etc., can solve the problems of limited flash removal accuracy, limited automation, process influence, etc., to achieve stable flash removal effect, The effect of high degree of automation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

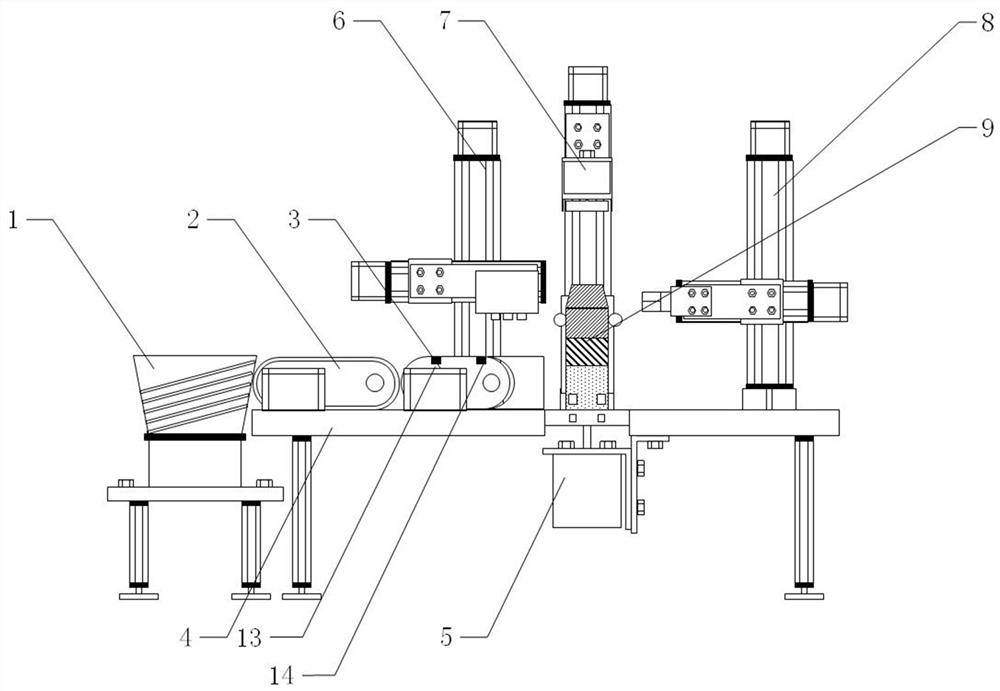

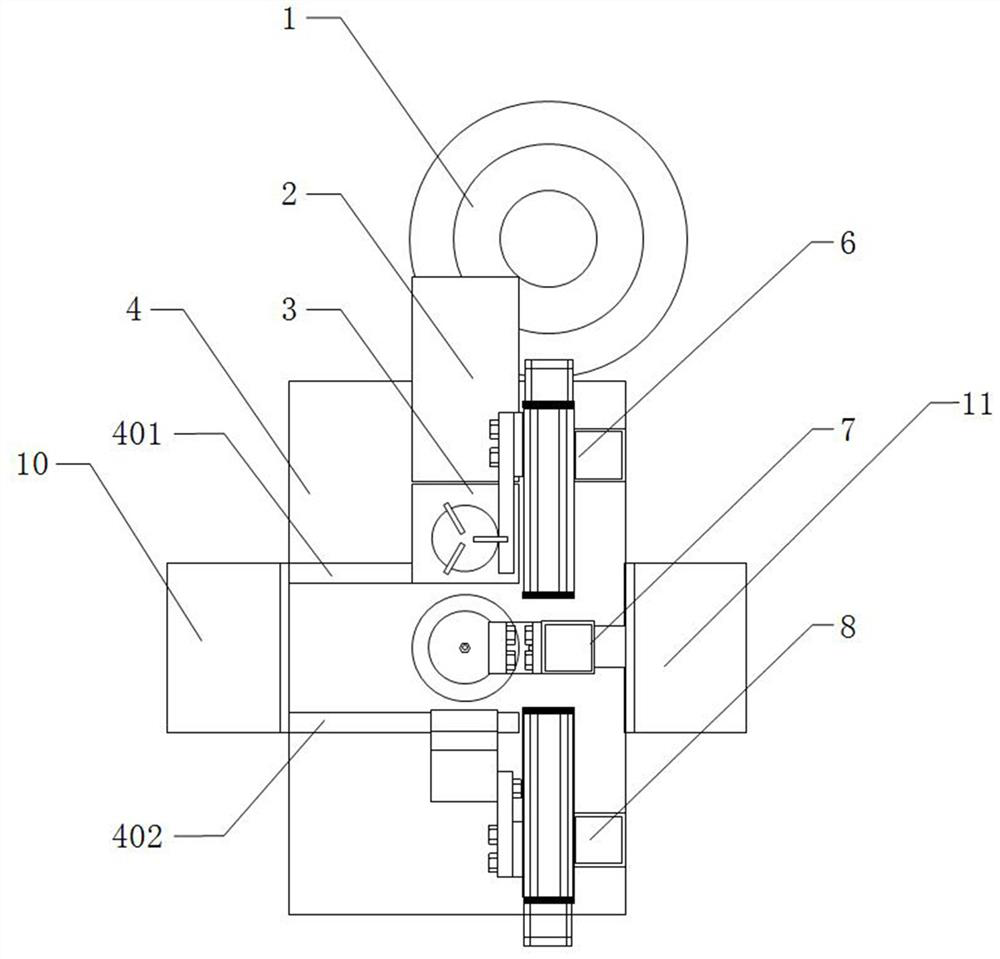

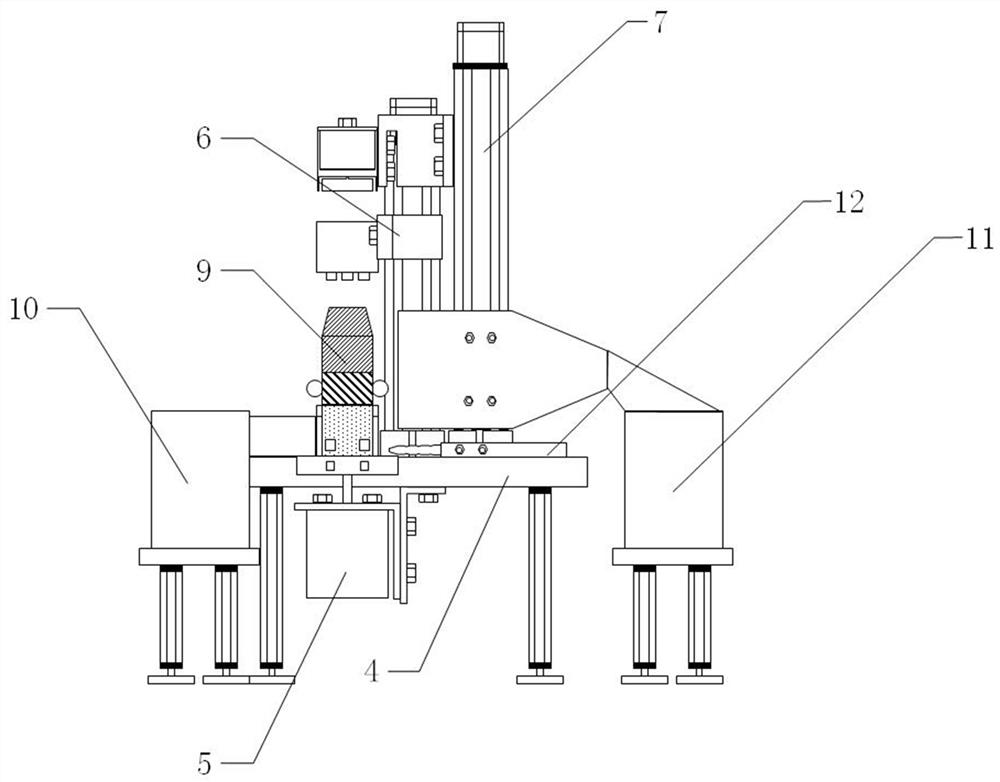

[0071] Such as Figure 1-Figure 10 Shown:

[0072] The present invention provides a high-precision automatic flash removal device for rubber sealing rings, which includes a vibration plate 1, a device platform 4, a motor assembly 5 and a mandrel 9, wherein:

[0073] The vibrating plate 1 and the device platform 4 are closely connected on the ground;

[0074] The motor assembly 5 is arranged at the bottom of the device platform 4;

[0075] The mandrel 9 is arranged above the motor assembly 5; the mandrel 9 is a metal rod with a taper at the top;

[0076] A clamping device 6, an auxiliary device 7 and a flash removal device 8 are arranged beside the mandrel 9;

[0077] Both the clamping device 6 and the flash removal device 8 are linear slide mechanisms with two degrees of freedom in the X-axis and the Z-axis;

[0078] The auxiliary device 7 is a Z-axis linear slide mechanism;

[0079] The device platform 4 is also provided with a product conveyor belt 2 and a buffer convey...

Embodiment 2

[0121] In this embodiment, a high-precision automatic flash removal device for rubber sealing rings is provided. Compared with Embodiment 1, the difference is that:

[0122] In this embodiment, the four corners of the device platform 4 are provided with support columns, further, the bottom of the support columns is provided with height-adjustable foot cups, and further, the support columns are 4040 aluminum profiles.

[0123] In this embodiment, the middle part of the device platform 4 is provided with an opening for matching with the motor platform 501 .

[0124] In this embodiment, the device platform 4 is provided with a plurality of threaded mounting holes; the product conveyor belt 2, the buffer conveyor belt 3, the clamping device 6, the auxiliary device 7 and the flash removal device 8 are all screwed on the device platform 4 superior.

[0125] In this embodiment, the motor body 504 is an adjustable variable speed brushless motor, and one end of its output shaft is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com