A kind of iron and steel industry nitrogen-containing wastewater treatment method

A waste water treatment, industry technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of low degree of automation, low utilization rate of carbon sources, and the impact of pollution in waste water To reduce investment and operating costs, accurately control the amount of carbon source dosage, save space and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

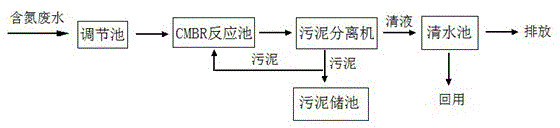

[0015] Example 1 The method of the present invention was used to treat high-concentration nitrogen-containing wastewater discharged from a cold rolling section of a steel plant.

[0016] (1) The waste water discharged from the cold rolling section of a steel plant is introduced into the regulating tank, and the average concentration of total nitrogen in the incoming water is 600 mg / L, the average concentration of COD is 40 mg / L, and the pH is between 6-9.

[0017] (2) Introduce nitrogen-containing wastewater into the CMBR reaction tank, the dosage of methanol is 1600mg / L, the dosage of potassium dihydrogen phosphate is 24mg / L; the denitrification rate is 0.06kgNO3-N∕(kgMLSS·d); sludge load 15g / L; there is a submersible mixer in the tank for mixing and mixing, with a residence time of 16h;

[0018] (3) Introduce the mixed liquid discharged from the CMBR reaction tank into the sludge separator. In this embodiment, the activated sludge separator is a vibrating membrane separator, using ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com