Photocuring 3D printer base heat dissipation structure

A technology for 3D printers and heat dissipation structures, applied in 3D object support structures, additive manufacturing, manufacturing tools, etc., can solve the problems of shortening the service life of 3D printers, low heat dissipation efficiency of fan rotation, and high temperature conditions, so as to reduce heat dissipation sources, Reduce the effect of increasing and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is attached Figure 1-5 The present invention is described in further detail.

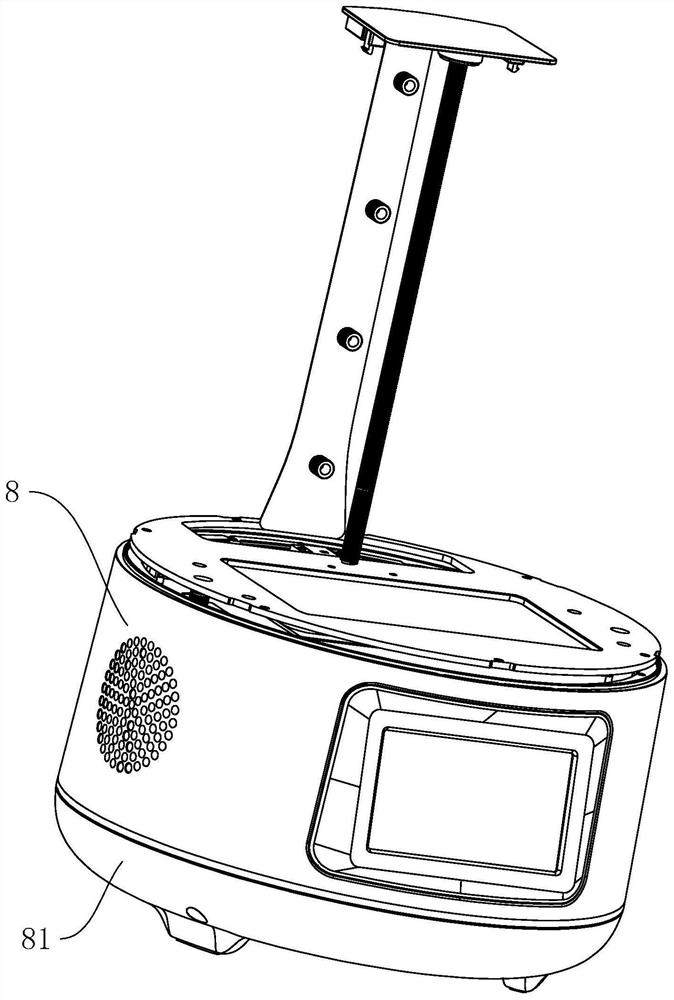

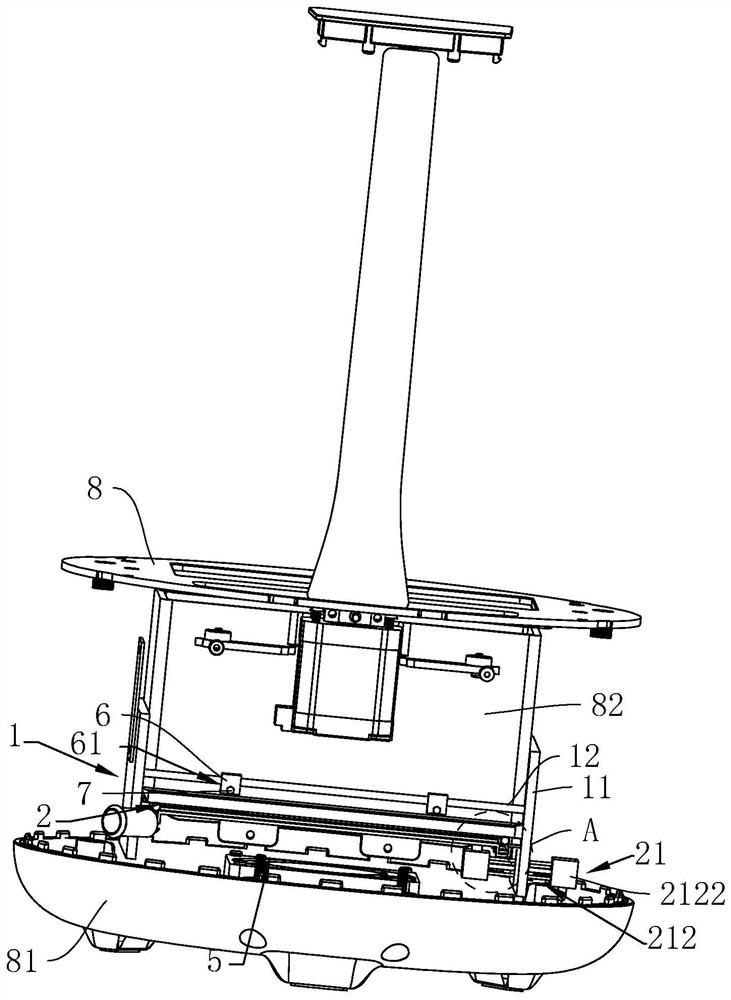

[0040] The embodiment of the present invention discloses a light-curing 3D printer base heat dissipation structure. refer to figure 1The heat dissipation structure of the light curing 3D printer base includes a support 1, a first heat dissipation member 2 and a second heat dissipation member 5, the first heat dissipation member 2 is located on the support 1, the second heat dissipation member 5 is located on the base 81, and the first heat dissipation member 2 and the second heat dissipation member 5 are convenient to accelerate the heat dissipation efficiency of the light source 82 and prolong the service life of the 3D printer 8 .

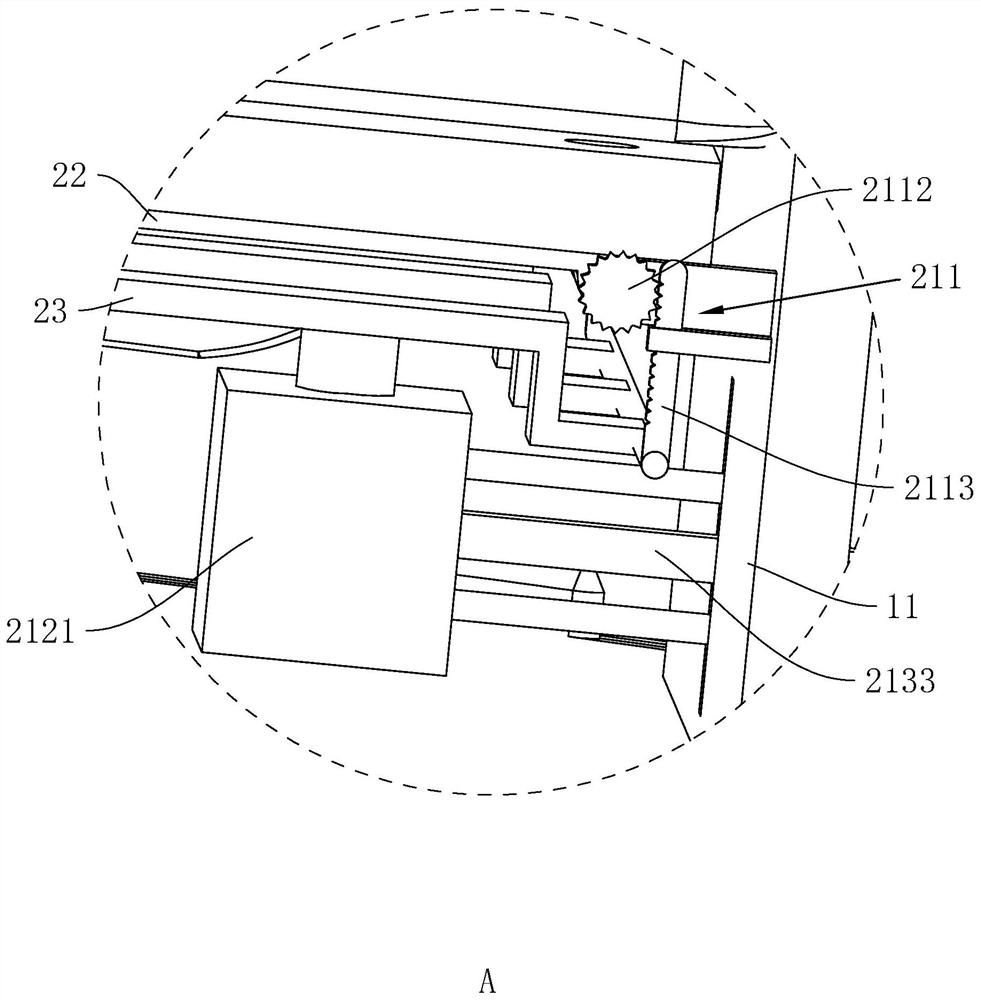

[0041] refer to figure 1 and figure 2 , the support member 1 includes two connecting plates 11 and two connecting rods 12, the two connecting plates 11 are respectively welded to the two ends of the connecting rod 12, and the two connecting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com