Anti-breaking auxiliary device for building construction and facilitating large glass unloading

A technology for building construction and auxiliary devices, which is used in transportation and packaging, load hanging components, cranes, etc., can solve the problems of inconvenient steering adjustment of glass, and achieve the effects of convenient docking, increased stability, and enhanced stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

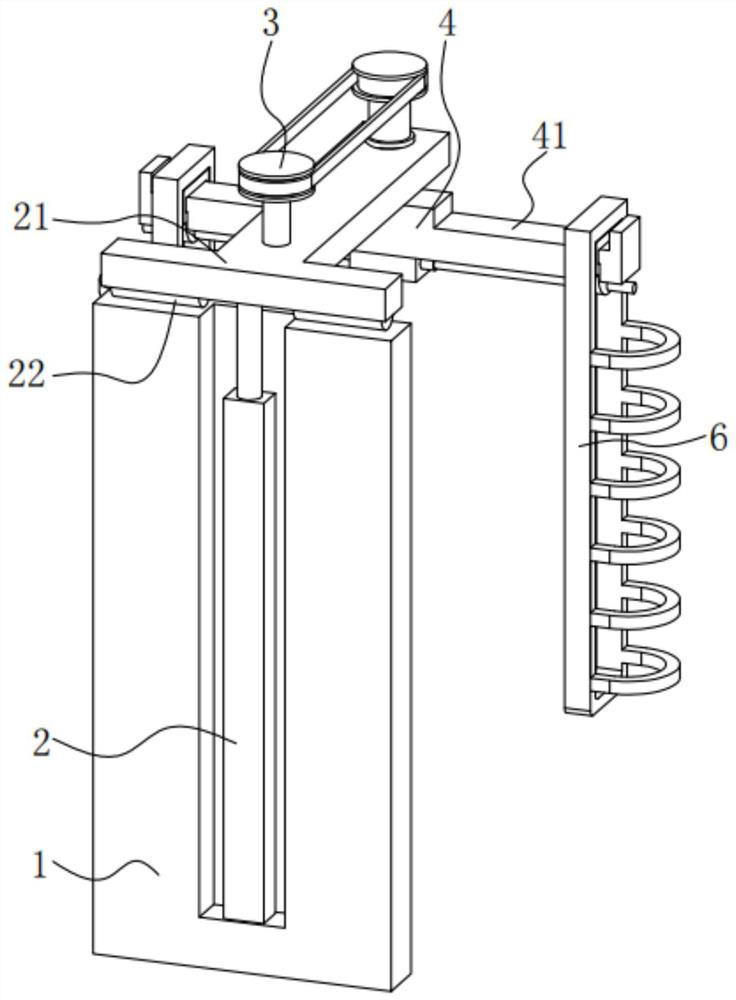

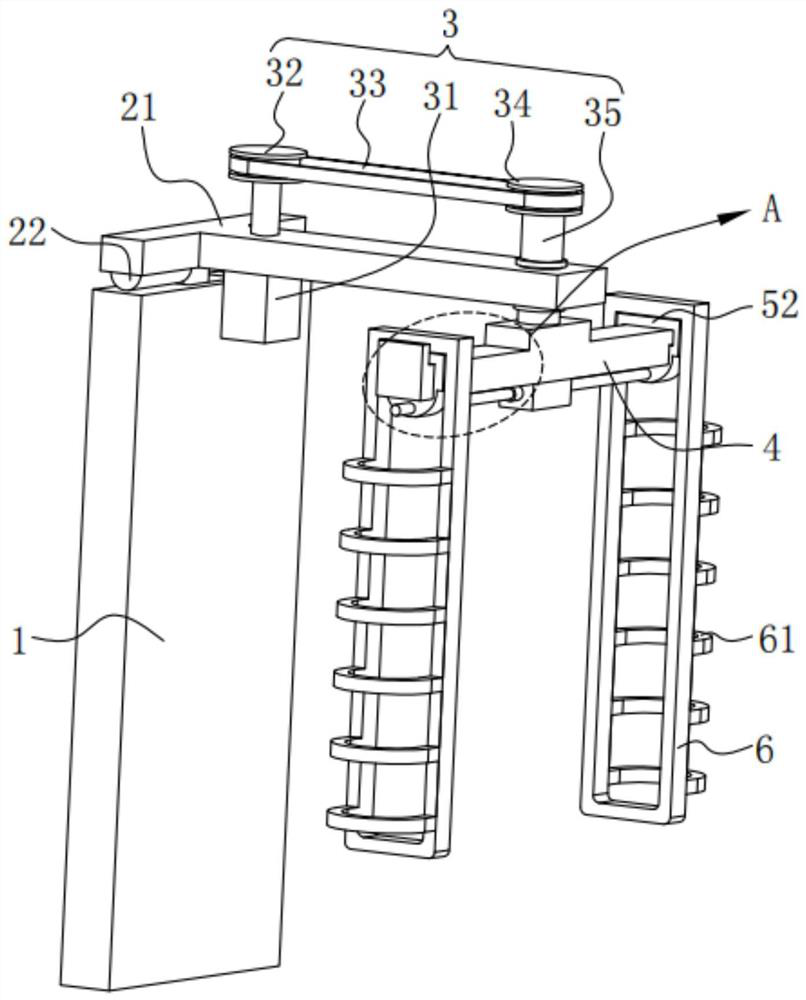

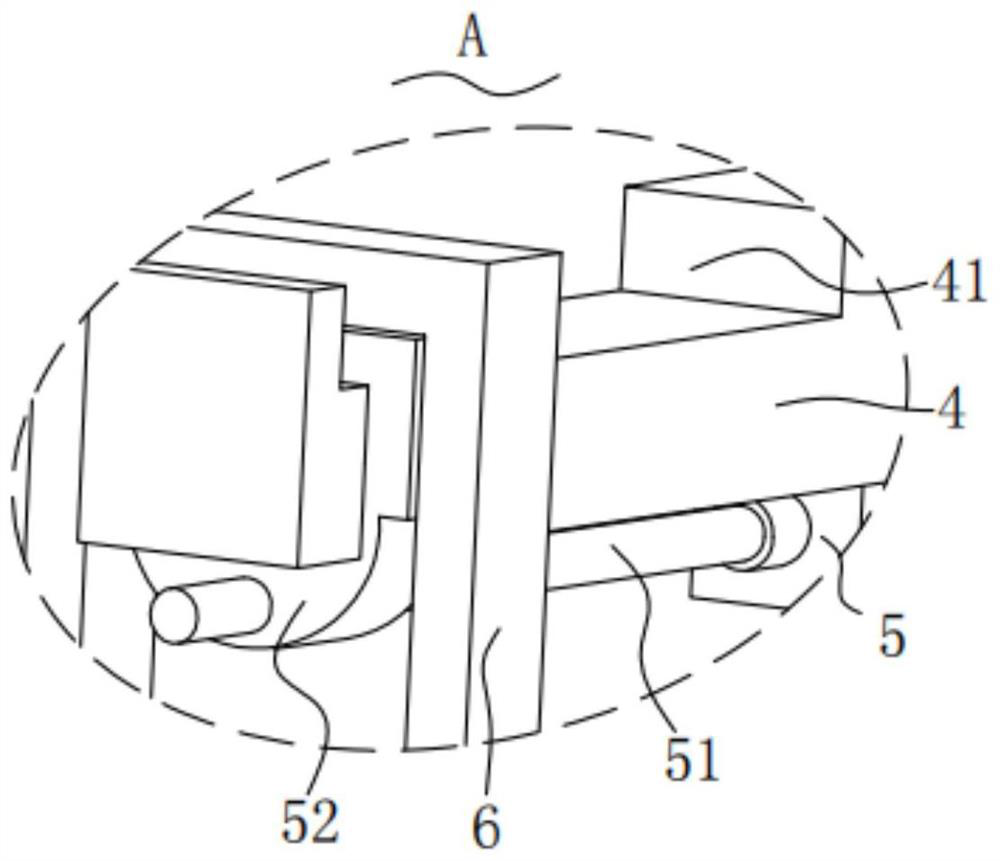

[0040] Please refer to figure 1 , figure 2 and image 3 ,in, figure 1 A three-dimensional view of the first embodiment of the anti-shattering auxiliary device for large-scale glass unloading provided by the present invention; figure 2 for figure 1 The overall structural schematic diagram shown; image 3 for figure 2 The enlarged schematic diagram of part A is shown.

[0041] An anti-shattering auxiliary device for building construction that is convenient for unloading large glass includes: a connecting frame 1; There is a support frame 21; a rotating assembly 3, the rotating assembly 3 is installed on the supporting frame 21, and the rotating assembly 3 includes a drive motor 31, a first pulley 32, a belt 33, a second pulley 34 and a linkage shaft 35; Linkage frame 4, the surface of described linkage frame 4 is installed on the output end of described rotating assembly 3, and limit chute 41 is offered on described linkage frame 4; Adjustment motor 5, the surface of d...

no. 2 example

[0069] see Figure 4 , Figure 5 , Figure 6 and Figure 7 , based on the anti-shattering auxiliary device for large-scale glass unloading provided by the first embodiment of the application, the second embodiment of the application proposes another anti-shattering auxiliary device for large-scale glass unloading for construction device. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment. Specifically, the difference between the anti-shattering and facilitating large-scale glass unloading auxiliary device for building construction provided in the second embodiment of the present application is that the anti-shattering and facilitating large-scale glass unloading auxiliary device for building construction also includes:

[0070] One side of the connecting frame 1 is rotatably installed with a telescopic member 7, and the output end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com