Expansion joint and pipe section arrangement and control method thereof

A technology for expansion joints and pipe sections, which is applied in the field of expansion joints and their pipe section layout and control, can solve the problems of easy damage of stainless steel corrugated pipes, affecting the life of the piping system, and the influence of pipe stress, etc., to achieve long service life, prolong service life, alleviate The effect of pipe section vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

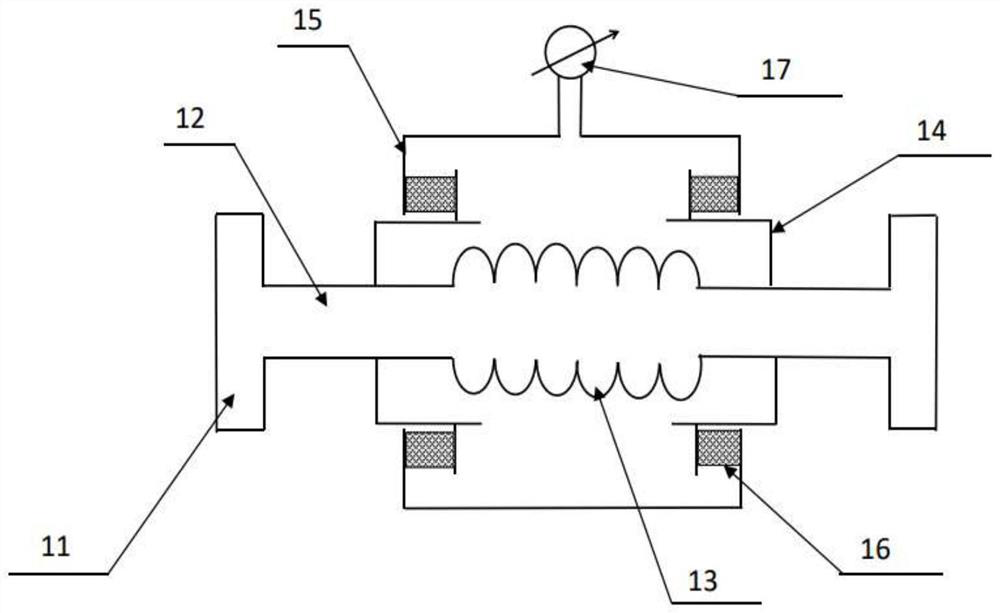

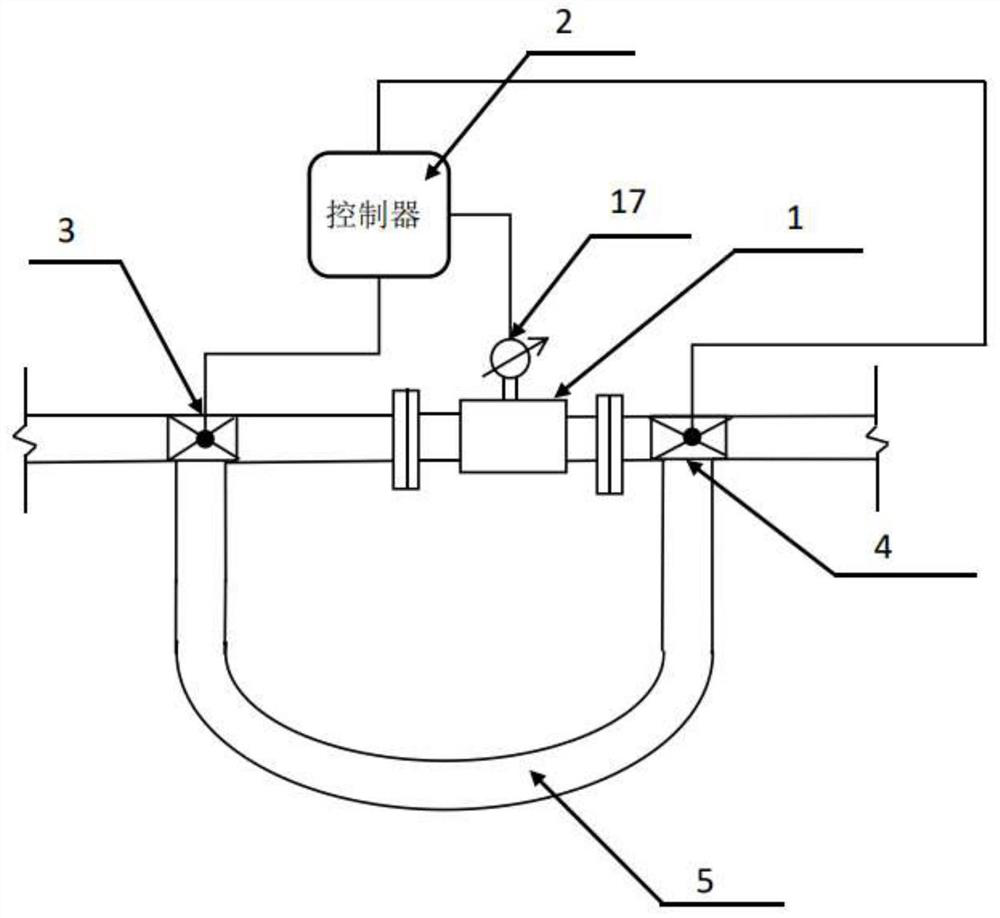

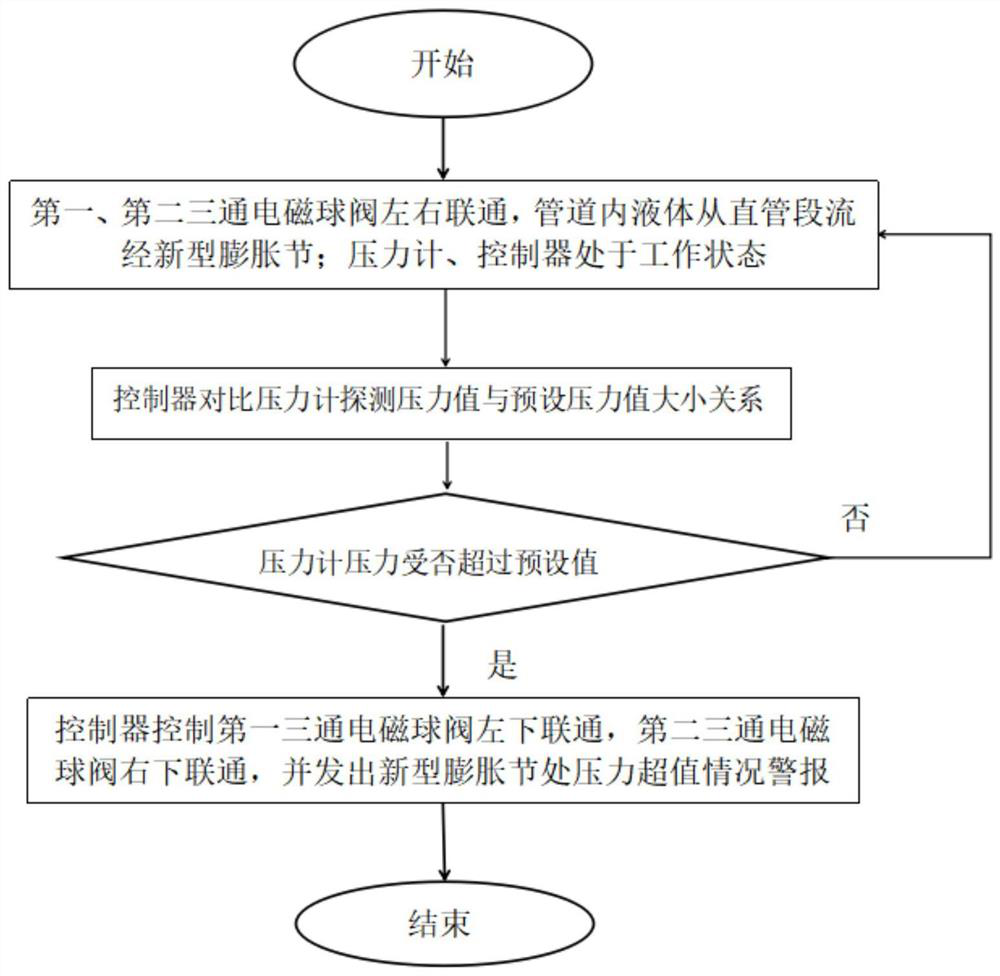

[0027] Such as figure 1 As shown, the expansion joint 1 of the present invention includes a flange 11, a connecting pipe 12, a bellows 13, a first cavity shell 14, a second cavity shell 15, a gasket block 16, and a pressure gauge 17, wherein the bellows The two ends of 13 are symmetrically welded with a connecting pipe 12, and the end of the connecting pipe 12 is welded with a flange 11, which is used for the connection between the expansion joint 1 and the pipe section. Welded with the bellows 13, on the one hand, it acts as a connection, and on the other hand, it is also the main supporting frame of the expansion joint 1.

[0028] The outer side of the bellows 13 is covered with a first cavity shell 14, the two ends of the first cavity shell 14 are respectively welded with the connecting pipe 12, the outer side of the first cavity shell 14 is set with a second cavity she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com