Battery compartment

A technology for battery compartments and batteries, which is applied in the field of battery compartments and can solve problems such as long replacement time and battery shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

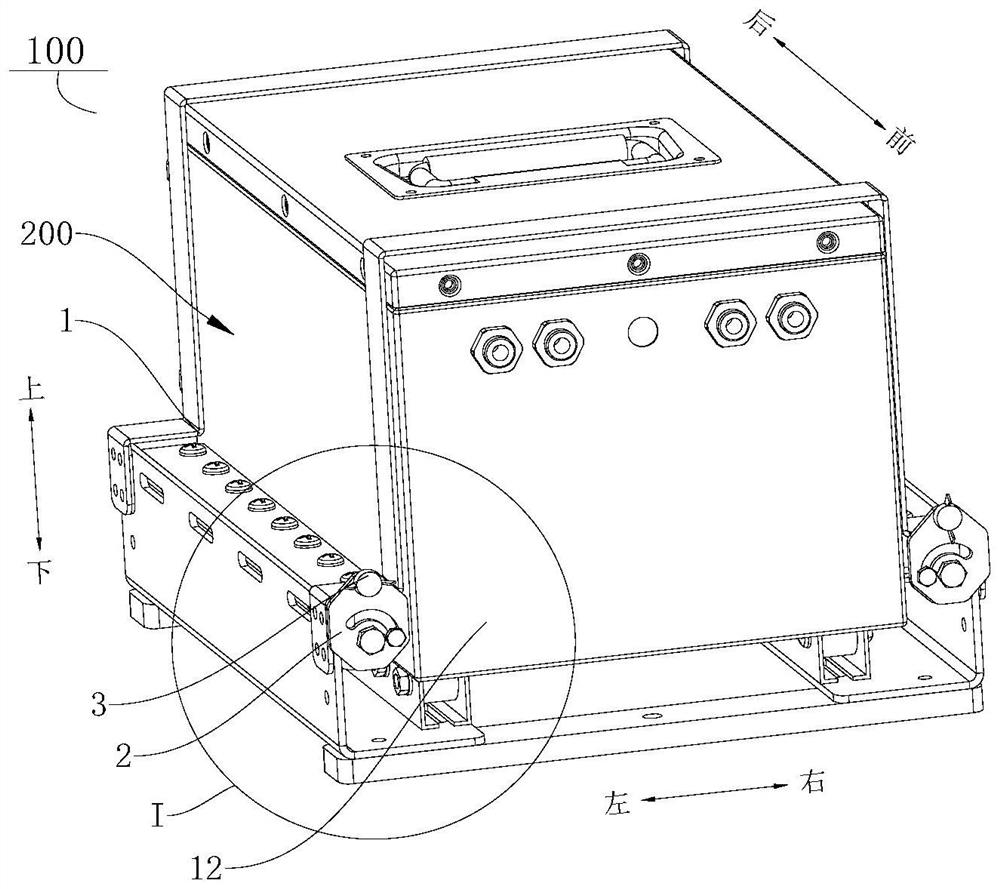

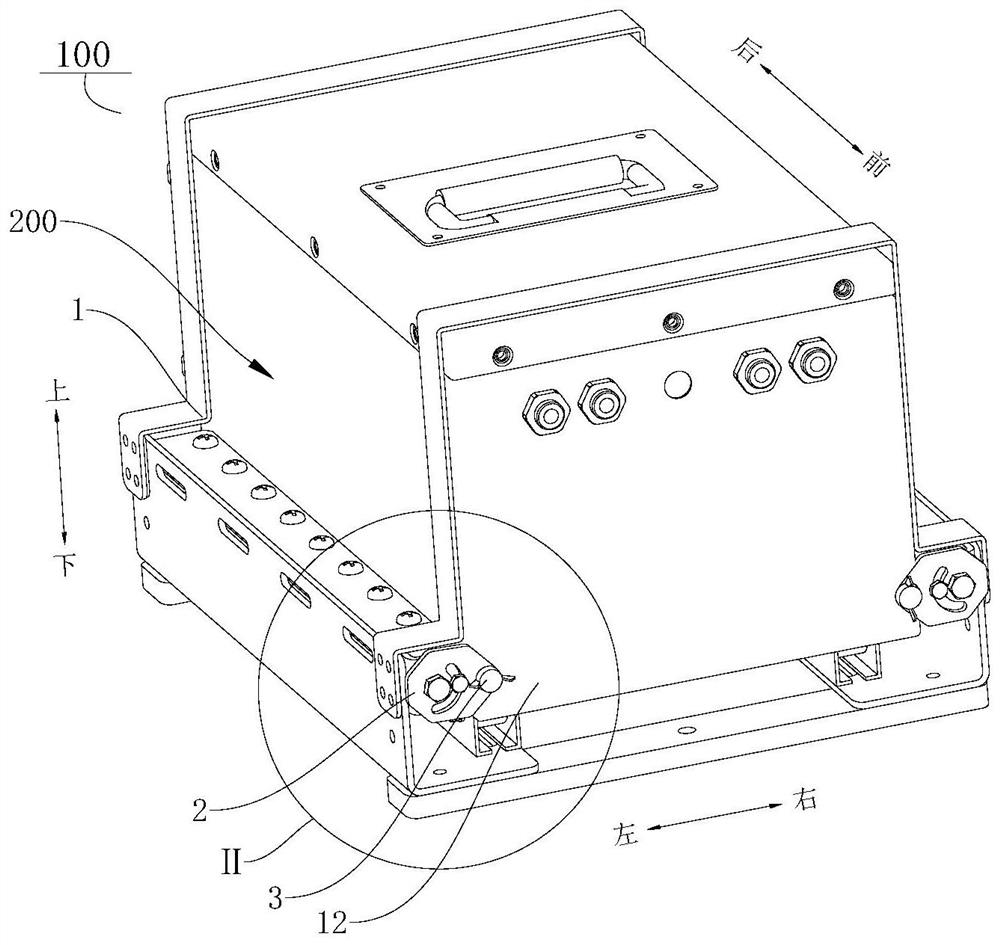

[0081] A battery compartment 100, such as figure 1 and figure 2 As shown, it includes: a warehouse body 1 , a first limiting member 2 and a second limiting member 3 .

[0082] Wherein, the bin body 1 is provided with an installation cavity, and the installation cavity is suitable for storing the battery 200 , and the bin body 1 is formed with an entrance 12 communicating with the installation cavity. The two first limiting members 2 are respectively arranged at the entrance and exit 12, and each first limiting member 2 can be switched between the first position and the second position, such as figure 1 As shown, in the first position, the first limiting member 2 is located outside the entrance and exit 12; as figure 2 As shown, in the second position, the second limiting member 3 blocks the entrance and exit 12 .

[0083] like figure 1 and figure 2 As shown, the second limiting member 3 is installed on the first limiting member 2, and when the first limiting member 2 m...

Embodiment 2

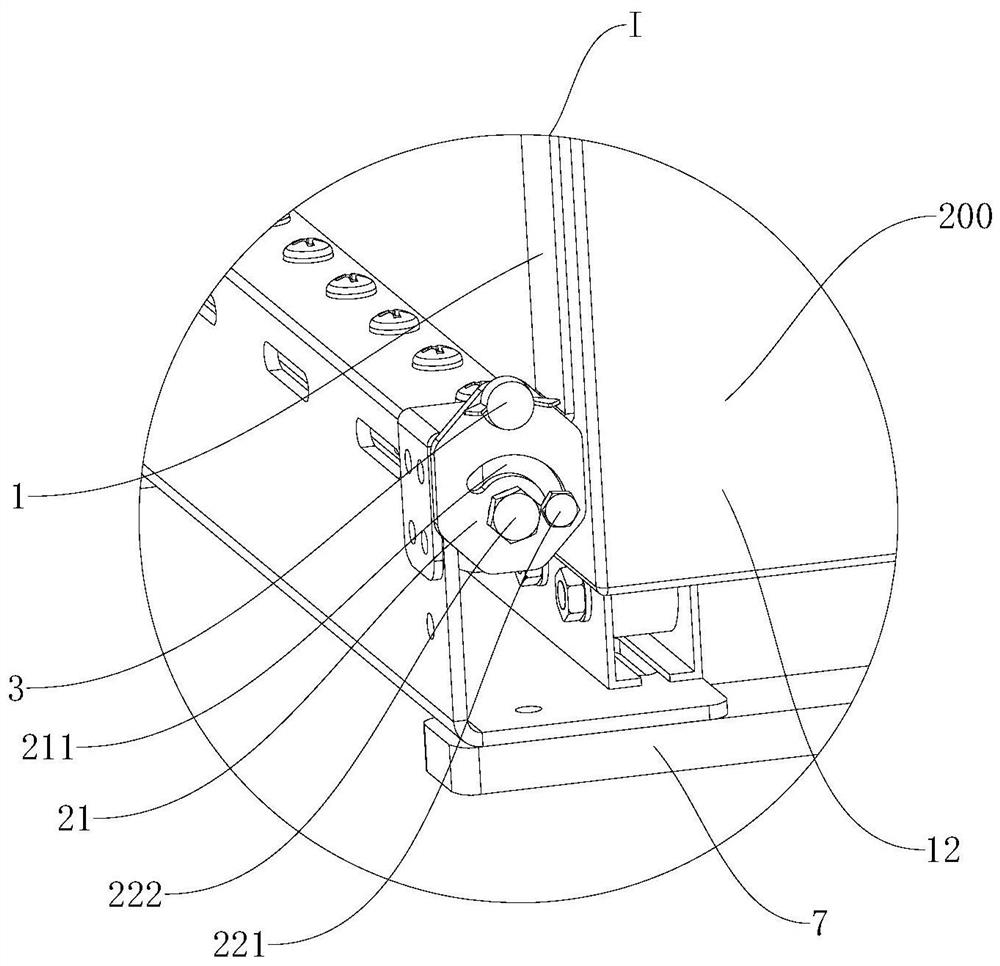

[0085] A battery compartment 100, different from Embodiment 1, on the basis of Embodiment 1, such as Figure 5 As shown, the first limiting member 2 includes: a baffle plate 21 and a matching plate 22 , the matching plate 22 is connected to the bin body 1 near the entrance 12 , and the baffle plate 21 is eccentrically rotatably connected to the matching plate 22 through a rotating shaft 222 . like image 3 As shown, one end of the baffle plate 21 protrudes to form a stop plate 212 , and the second limiting member 3 is arranged on the stop plate 212 . like image 3 and Figure 4 As shown, the baffle plate 21 is provided with an arc-shaped limiting groove 211 , and the matching plate 22 is provided with a guiding connector 221 , and the guiding connecting member 221 is slidably arranged in the arc-shaped limiting groove 211 .

[0086] When the baffle plate 21 on the left is switched from the first position to the second position, the baffle plate 21 rotates clockwise along th...

Embodiment 3

[0088] A battery compartment 100. The difference from Embodiment 2 is that on the basis of Embodiment 2, the second limiting member 3 is a butterfly valve, and the first limiting member 2 is provided with a through bolt hole 213. The butterfly valve The valve is threaded with the bolt hole 213, such as Figure 4 As shown, when the first limiting member 2 is in the second position, the butterfly valve stops against the battery 200 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com