Circuit board and hole forming method thereof

A circuit board and hole technology, which is applied to the formation of electrical connections of printed components, printed circuits, printed circuits, etc., can solve the problems of reduced reliability of circuit boards, limited capacity of conductive materials, cracks, etc., to reduce the probability of cracks and improve reliability. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

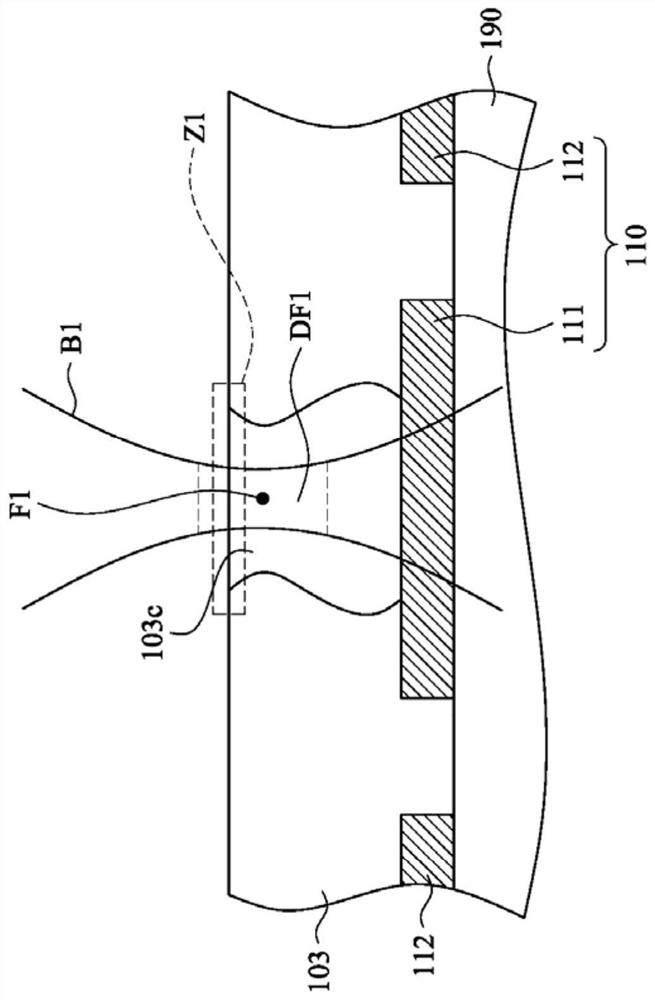

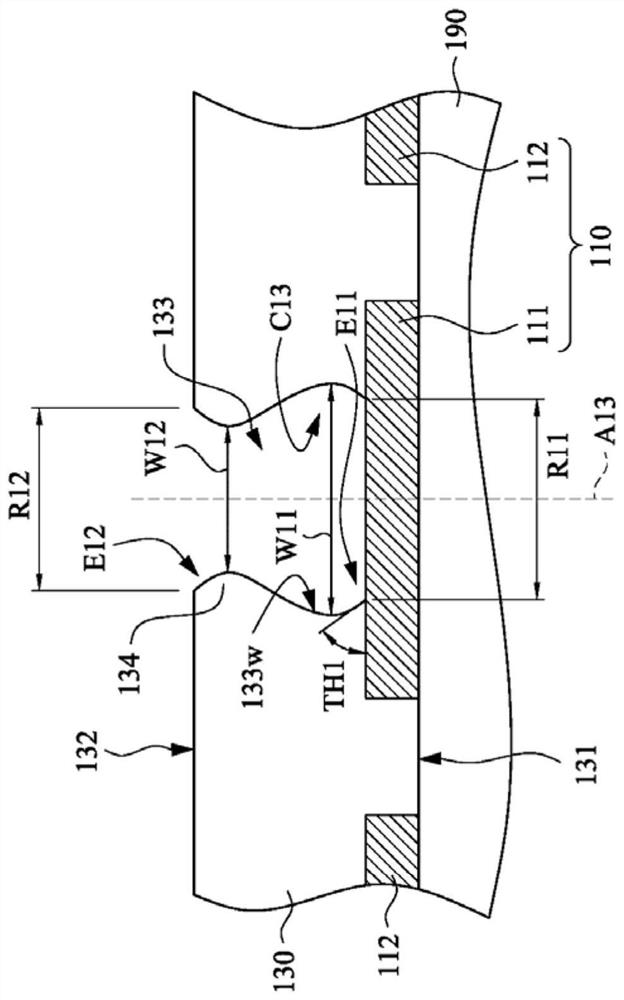

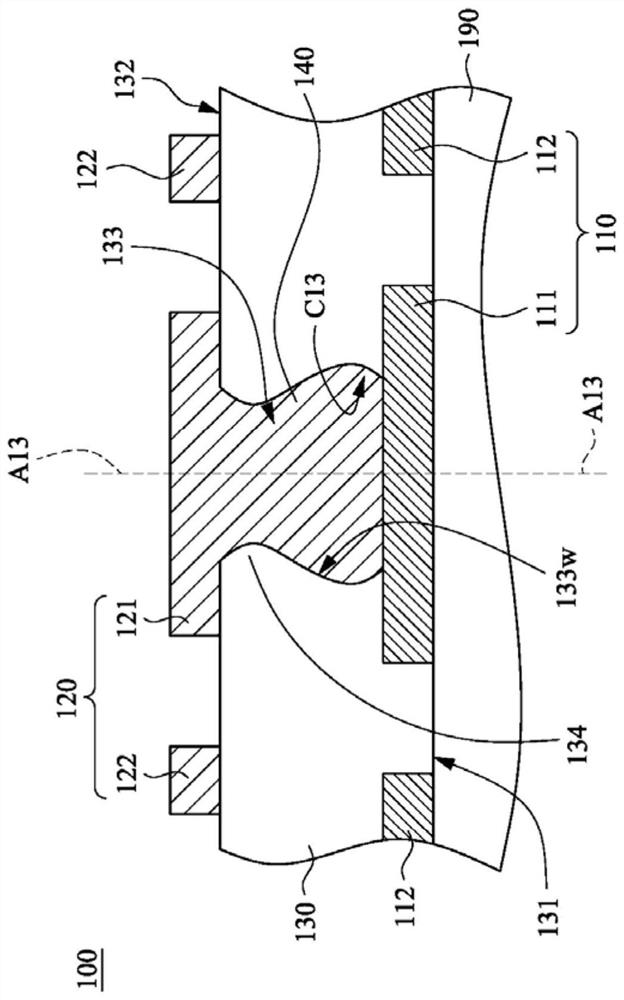

[0044] In the following text, in order to clearly present the technical features of this application, the dimensions (such as length, width, thickness, and depth) of elements (such as layers, films, substrates, and regions) in the drawings will be enlarged in a non-proportional manner . Therefore, the description and explanation of the following embodiments are not limited to the size and shape of the elements in the drawings, but should cover the deviations in size, shape and both caused by actual manufacturing process and / or tolerances. For example, a planar surface shown in the drawings may have rough and / or non-linear features, while acute angles shown in the drawings may be rounded. Therefore, the components shown in the drawings of this case are mainly for illustration, and are not intended to accurately depict the actual shape of the components, nor are they used to limit the scope of the patent application of this case.

[0045] Secondly, words such as "about", "appro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com