Multi-stage efficient sand washing device

A high-efficiency and sand-washing technology, which is applied in the cleaning method using liquid, solid separation, wet separation, etc. problem, to achieve the effect of improving the cleaning efficiency, washing the sand completely and thoroughly, and increasing the contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

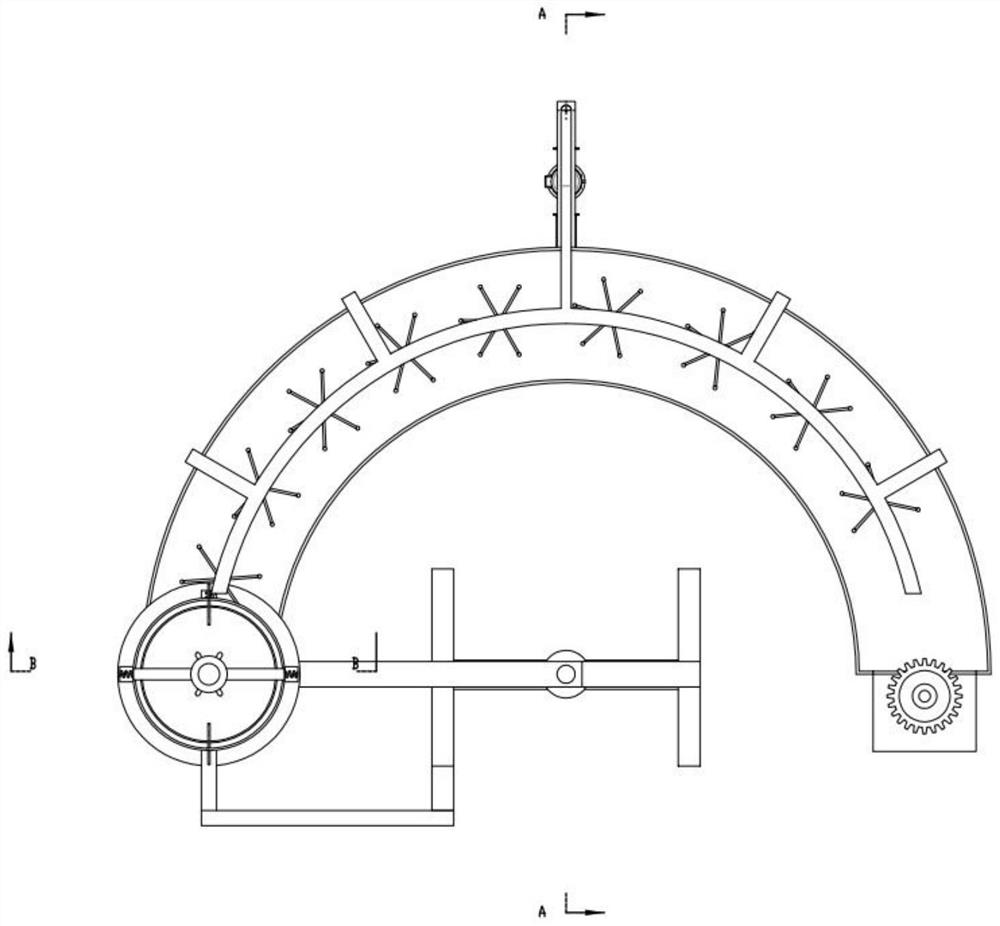

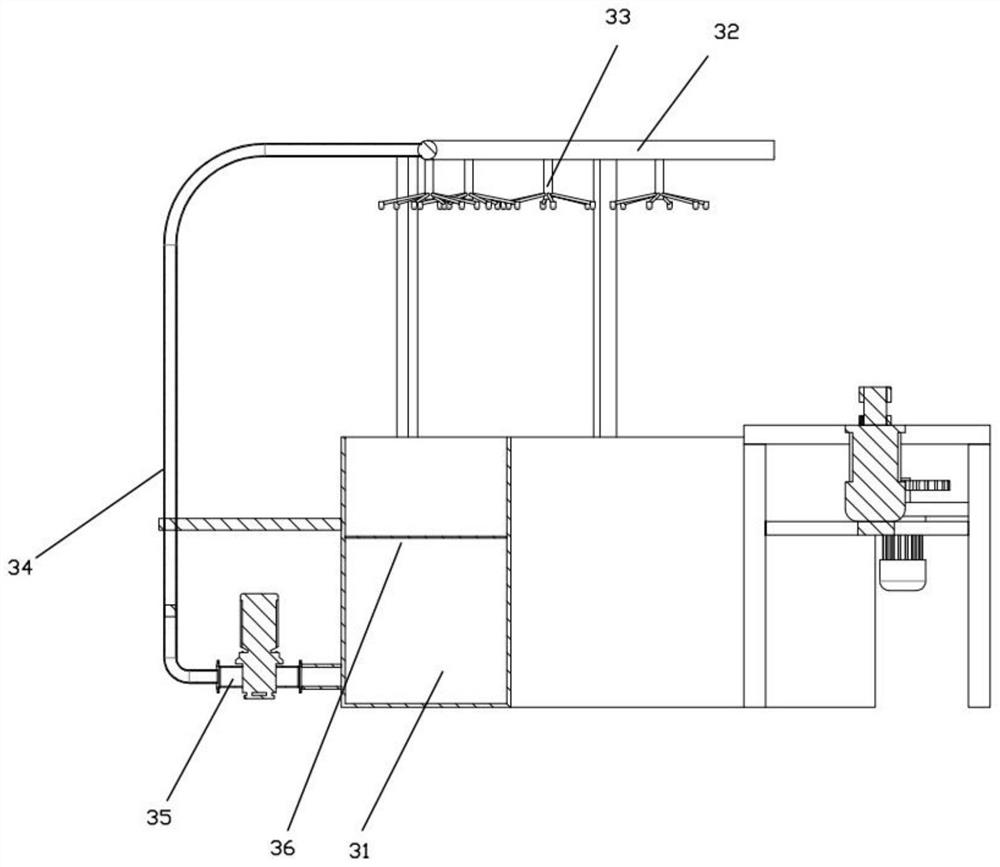

[0035] Please also refer to Figure 1 to Figure 6 , the multi-stage high-efficiency sand washing device of the embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

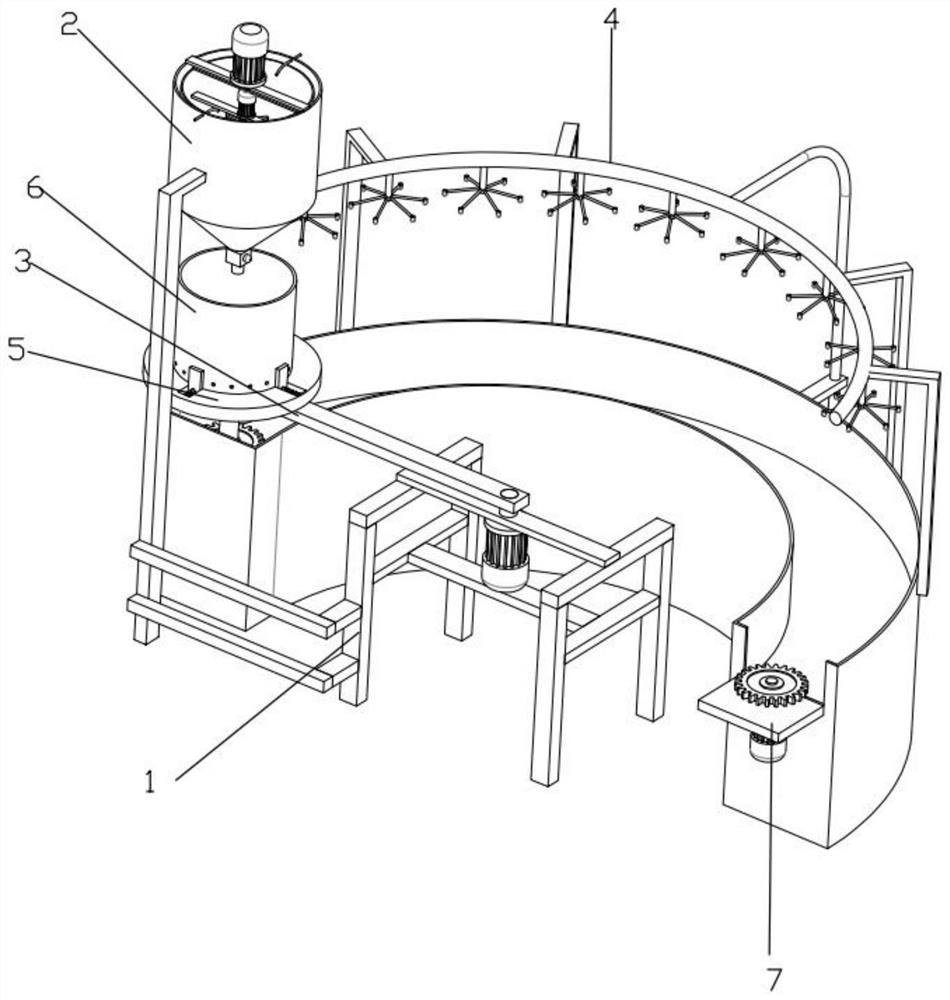

[0036] The multi-stage high-efficiency sand washing device includes a bracket 1, a broken cleaning component 2, a transfer component 3, a transfer cleaning component 4, a fixed component 5, a transfer cylinder 6, and a centrifugal collection component 7. The middle part of the bracket 1 is rotatably connected to the transfer component 3. The transfer assembly 8 can rotate back and forth between the crushing cleaning assembly 2 and the centrifugal collection assembly 7, the crushing cleaning assembly 2 and the centrifugal collection as...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap