A mobile phone card and card tray automatic disassembly and marking production line and production process

A technology for automatic disassembly and assembly of mobile phone cards, applied in manufacturing tools, metal processing equipment, manufacturing computing systems, etc., can solve problems such as the inability to realize automatic disassembly and assembly of card trays, SIM card chip automatic assembly, etc., to save labor costs, reduce The overall volume and the effect of improving the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

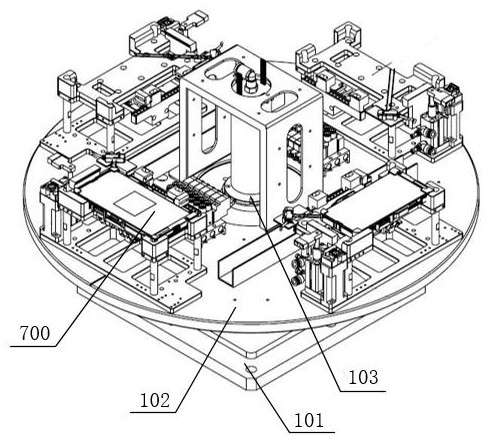

[0061] like figure 1 As shown, this embodiment provides a production line for automatic disassembly and assembly of mobile phone cards and card trays, including a control device, a rotating device 100, and a loading and unloading device 200 and a card tray dismantling device arranged in sequence along the circumferential direction of the rotating device 100. 300, a laser engraving device 400 and a card loading device; the control device is respectively connected with the rotating device 100, the loading and unloading device 200, the card removing device 300, the laser engraving device 400, and the card loading device;

[0062] The loading and unloading device 200 is used to transfer the mobile phone to be marked into the rotating device 100;

[0063] The card tray removal device 300 is used to perform the card tray removal operation on the mobile phone transferred by the loading and unloading device 200;

[0064] The laser engraving device 400 is used to perform the marking o...

Embodiment 2

[0134] The present embodiment proposes a production process for automatic disassembly and assembly of mobile phone cards and card trays, which includes the following steps:

[0135] S1, through the loading assembly 201 of the loading and unloading device 200, the mobile phone to be marked on the feeding line is transferred to the feeding sliding table 202, and the feeding sliding table 202 transfers the mobile phone to be marked to the first transfer A mechanism 203, the first transfer mechanism 203 transfers the mobile phone to be marked to the rotating device 100;

[0136] S2, the rotating device 100 rotates 90 degrees counterclockwise, and transfers the mobile phone transferred by the first transfer mechanism 203 to a position corresponding to the card removing device 300; return to step S1, and execute step S3 at the same time;

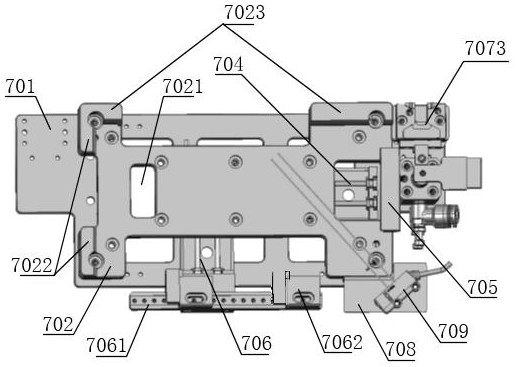

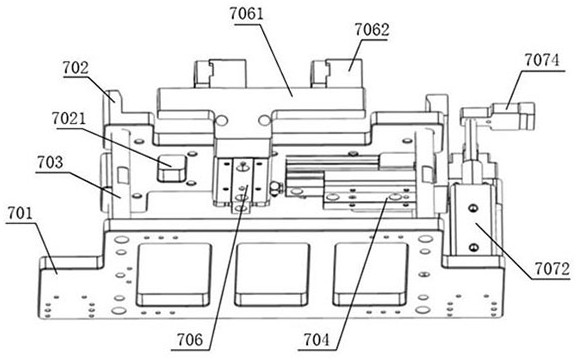

[0137] S3, the air gripper module 305 and the CCD positioning module 304 are driven to move by the three-dimensional moving module on the card ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com