Printing equipment for testing liquid performance and control method thereof

A technique of printing equipment and a control method, which is applied to printing devices, printing, transfer materials, etc., can solve the problems of fewer liquid types, small liquid volume ranges, and large limitations, and achieve a wide testing range and increase the testing volume range , the effect of improving applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

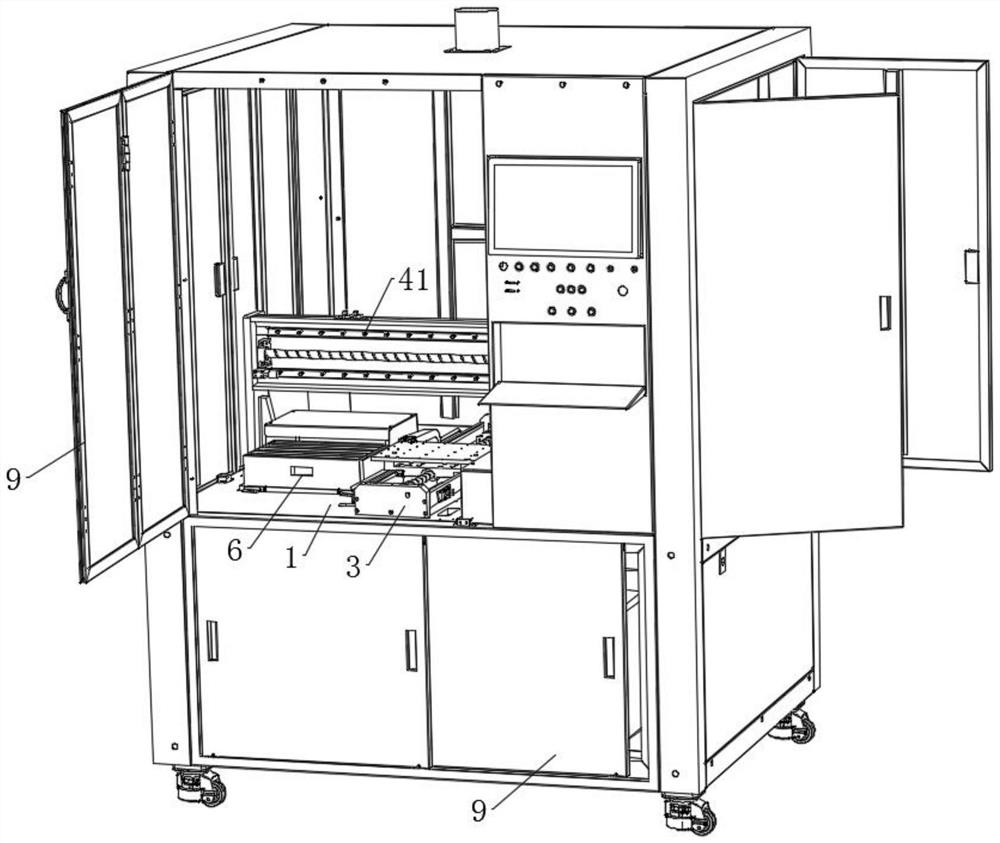

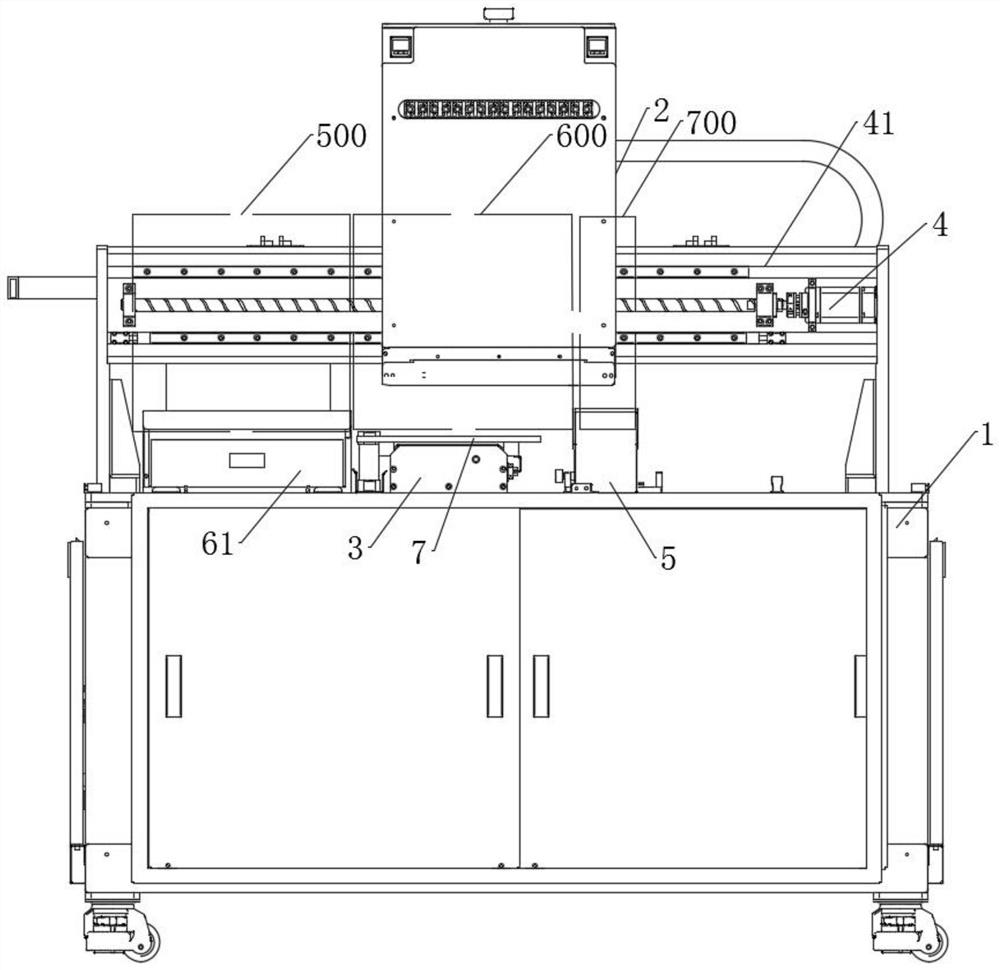

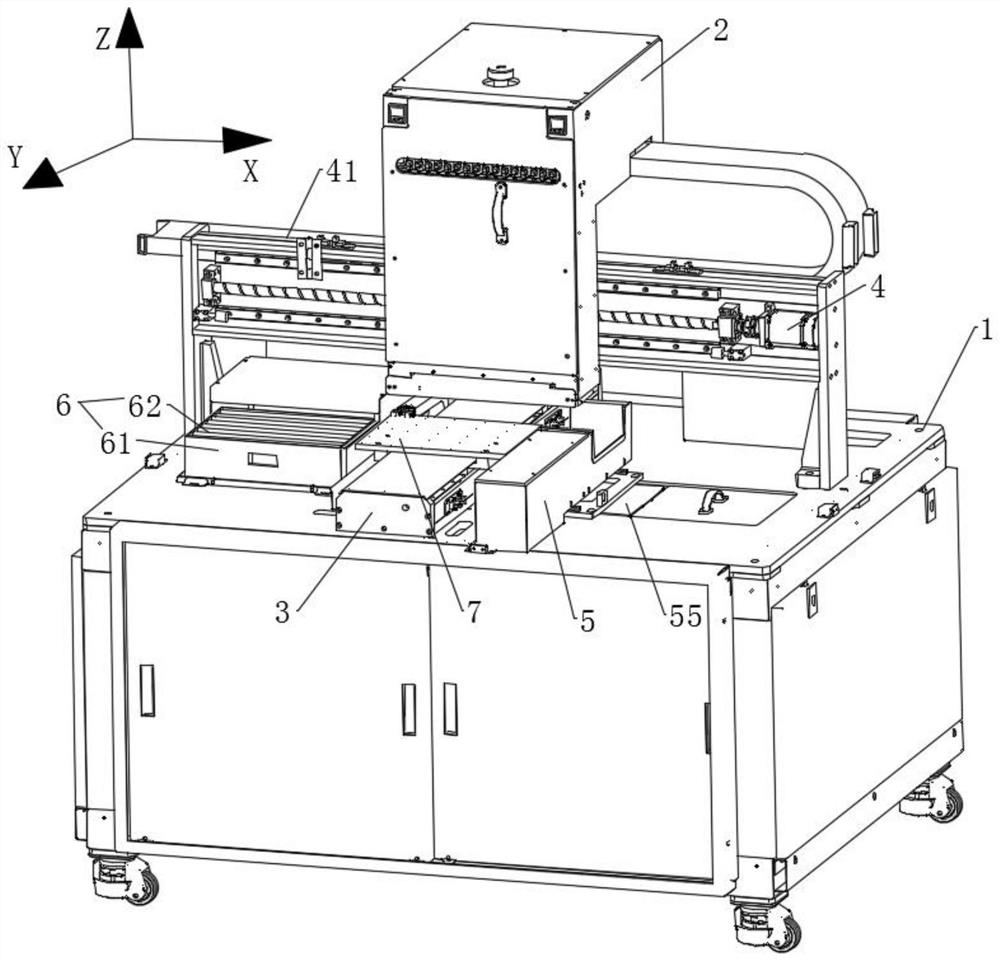

Embodiment 1

[0049] Embodiment 1 of the present invention provides a printing device for testing liquid properties. The tested liquid properties include: at least one of the number of satellite dots of ink dots, the printing straightness of ink dots, and the uniformity of ink dot size. Of course, in order to obtain More accurate liquid performance can also include other liquid test performance, such as fluency, etc., and the specific test that needs to be applied is not limited here. All parameters that can characterize the performance of printing liquids are covered by the protection of the present invention. within range. Specifically, the liquid performance test is to control the dot images formed by spraying a single row of nozzles on the printing medium once, and observe the corresponding characteristics of each dot image to obtain the performance of the ink. In order to verify the corresponding performance of the ink under various ejection volumes, different ejection volumes are used...

Embodiment 2

[0141] Embodiment 2 of the present invention is improved on the basis of Embodiment 1, combining figure 2 as well as Figure 11 As shown, the liquid observation mechanism 5 is specifically provided, and further, the liquid observation mechanism 5 includes: a collection part 53, and the collection part 53 is used to collect the liquid droplet images ejected by the nozzles of several spray heads within a preset time; the collection of the collection part 53 The scope covers at least the jetting surface of the nozzle, and the collection part 53 adopts a camera, and its collection range is spread out from the axis of the collection part 53 to the surroundings, and presents a collection angle from a side view, that is to say, the method adopted in this application is to collect The image captured by section 53 is the liquid starting from the nozzle leaving the spray head.

[0142] to combine Figure 14 as well as Figure 11 As shown, the liquid observation mechanism 5 includes ...

Embodiment approach 2

[0163] The second aspect of the present invention provides a printing device control method, which is used to control the printing device described in any one of the above, combined with Figure 17 As shown, the method includes:

[0164] Controlling the first type of nozzle in the at least two types of nozzles to be located in the zero adjustment zone;

[0165] Perform zero adjustment processing on the first type of nozzle;

[0166] After the first type of nozzle is adjusted to zero, control the first type of nozzle to move to the printing area to eject the liquid to the first designated area of the printing medium;

[0167] After the first type of nozzle is sprayed, control the second type of nozzle to move to the zero adjustment area;

[0168] After the second type of nozzle is zero-adjusted, the second type of nozzle is controlled to move to the printing area to eject liquid to a second designated area of the printing medium.

[0169] In the present invention, the pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap