Automatic film wrapping machine for yarn roll

A coating machine and yarn ball technology, applied in the field of yarn ball automatic coating machine, can solve the problems of increasing labor intensity and low efficiency of workers, and achieve the effects of improving coating efficiency, convenient operation, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

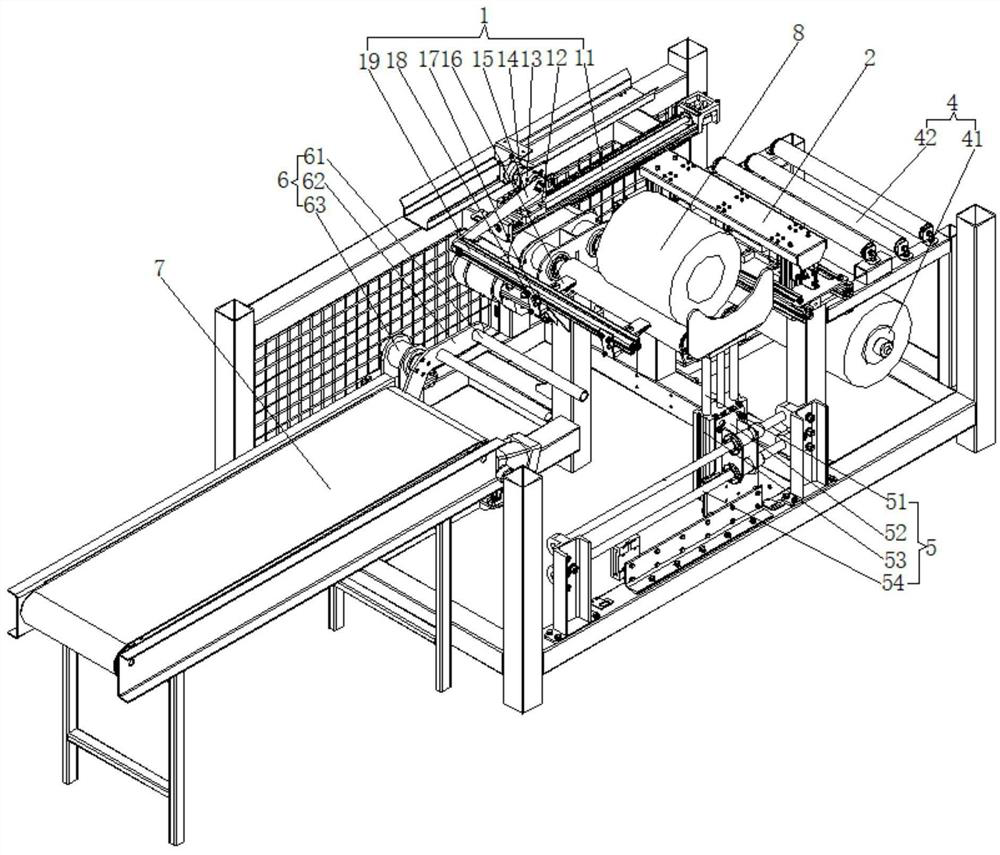

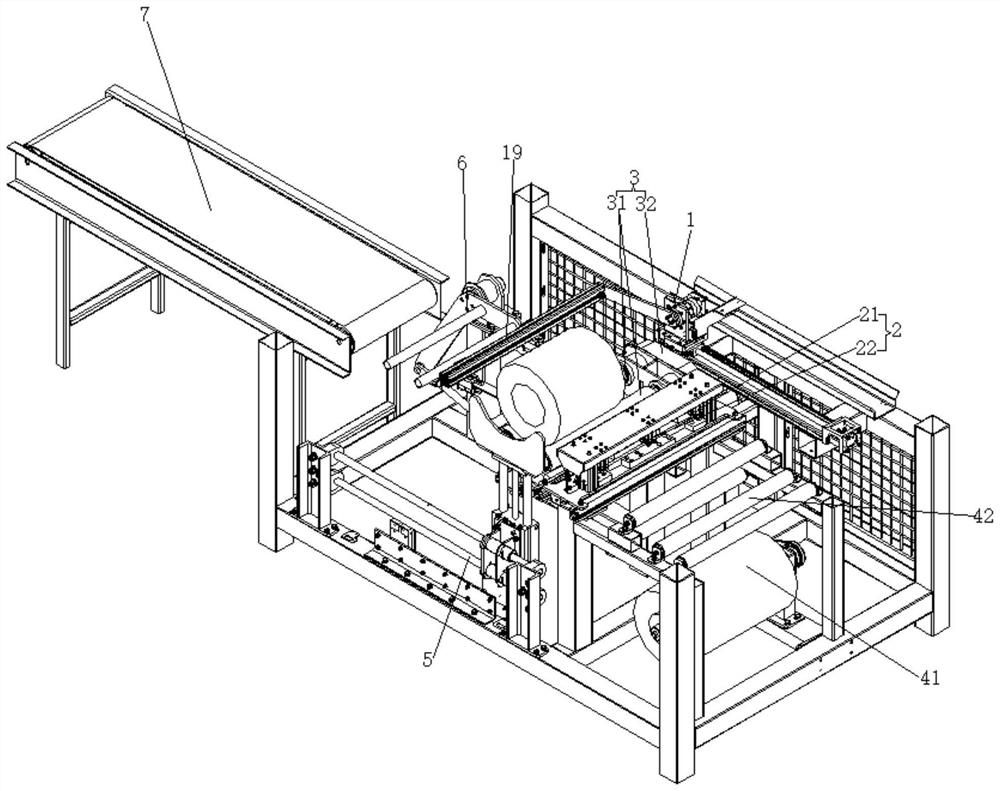

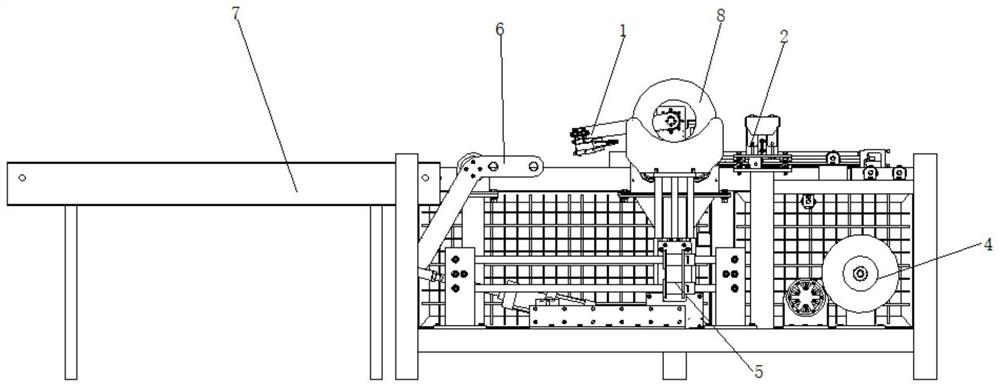

[0025] Example 1: See Figure 1-3 , the present invention provides a technical solution: an automatic yarn wrapping machine, comprising:

[0026] Laminating mechanism 2, used to compress the drawn film and carry out

[0027] Cut off, film lamination mechanism 2 comprises compression cylinder 21 and film cutting cylinder 22, the quantity of compression cylinder 21 is two groups, the quantity of film cutting cylinder 22 is one group, two groups of compression cylinders 21 are respectively arranged on cutting film cylinder 22 The two sides of film cutting cylinder 22 and compression cylinder 21 are arranged in two rows, and each row is two compression cylinders 21 and one film cutting cylinder 22;

[0028] The upper film mechanism 4 is arranged on one side of the lamination mechanism 2, and is used to place the film and control the tightness of the film. The upper film mechanism 4 includes a driving roller 41 and an upper film roller 42, and the driving roller 41 is arranged on ...

Embodiment 2

[0035]Embodiment 2: The difference from Embodiment 1 is that the film taking mechanism 1 also includes a mounting plate 17 and fixing bolts 18, the mounting plate 17 is connected with the rotating plate 19 through the fixing bolts 18, and the finger cylinder 16 is arranged on the mounting plate 17 , by connecting the finger cylinder 16 with the rotating plate 19 through the fixing bolt 18, adjust the distance between two finger cylinders 16 according to the width of the film, so as to facilitate the adjustment of the suitable position for clamping the film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com