Foam material foaming machine

A foam material and foaming machine technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problem of uncontrollable bubble size, bubble distribution uniformity, bubble number, bubble volume ratio, nano particle damage, material Performance discount and other issues, to achieve the effect of expanding the application range and application space, solving the problem of material resources, and uniform bubble size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

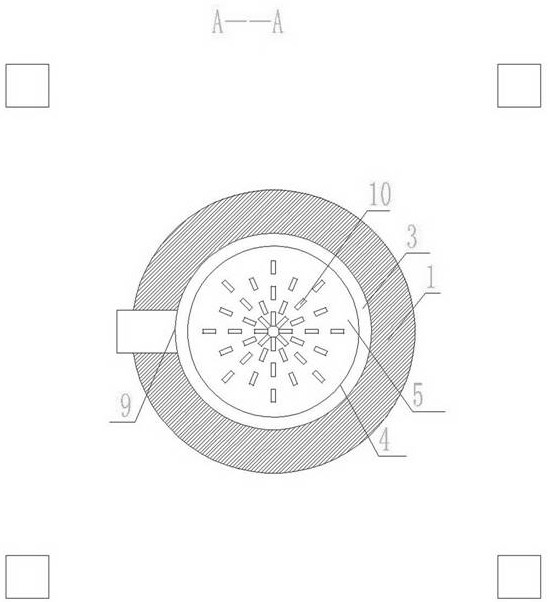

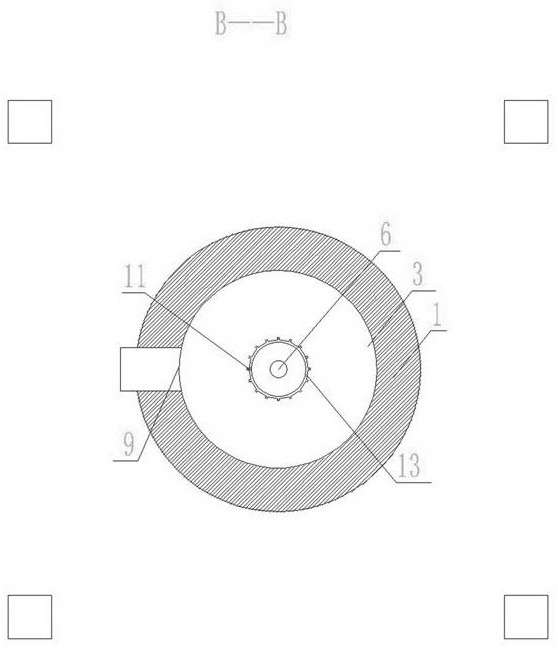

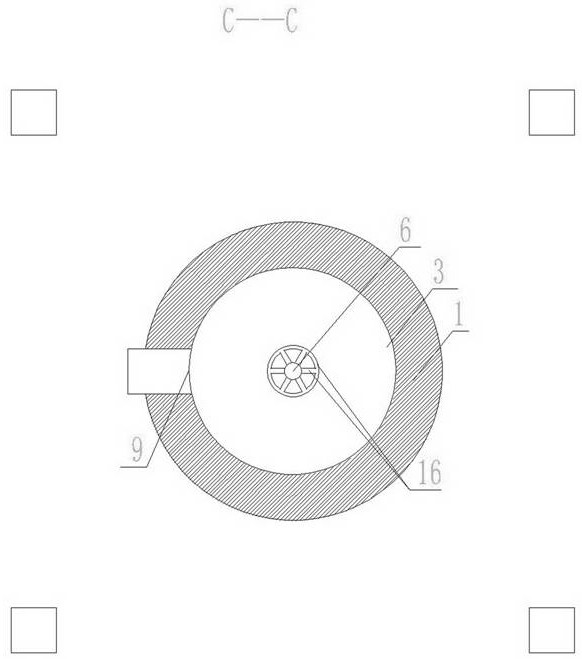

[0031] The main structure of the foam material foaming machine of the present invention includes a housing 1 and a transmission device 2, the transmission device 2 is arranged on the housing 1, a housing chamber 3 is arranged in the housing 1, a rotary grinding and foaming wheel 4 is arranged in the housing chamber 3, and the transmission The device 2 is connected with the rotary grinding and foaming wheel 4, and the rotary grinding and foaming wheel 4 is provided with a rotary grinding and foaming moving disk surface 5, and the shell cavity 3 corresponds to the rotating grinding and foaming moving disk surface 5. The middle part of the shell cavity inlet 6 is set, and the shell cavity inlet 6 is surrounded The inner wall of the housing chamber 3 is provided with a rotary grinding and foaming static disk surface 7, the rotary grinding and foaming dynamic disk surface 5 is close to the rotary grinding and foaming static disk surface 7, and a rotating grinding and foaming static d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com