Foam material generator

一种泡沫材料、发生器的技术,应用在化学仪器和方法、混合机、混合方法等方向,能够解决无法控制气泡大小气泡分布均匀度、气泡数量气泡所占体积比例、纳米颗粒破坏、材料性能折扣等问题,达到拓展应用范围和应用空间、解决材料资源问题、减少资源用量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

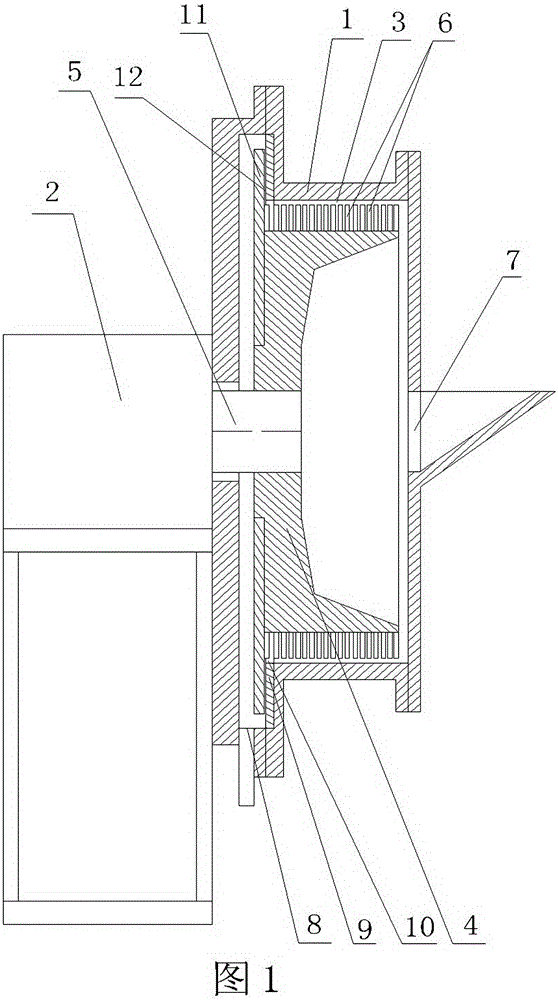

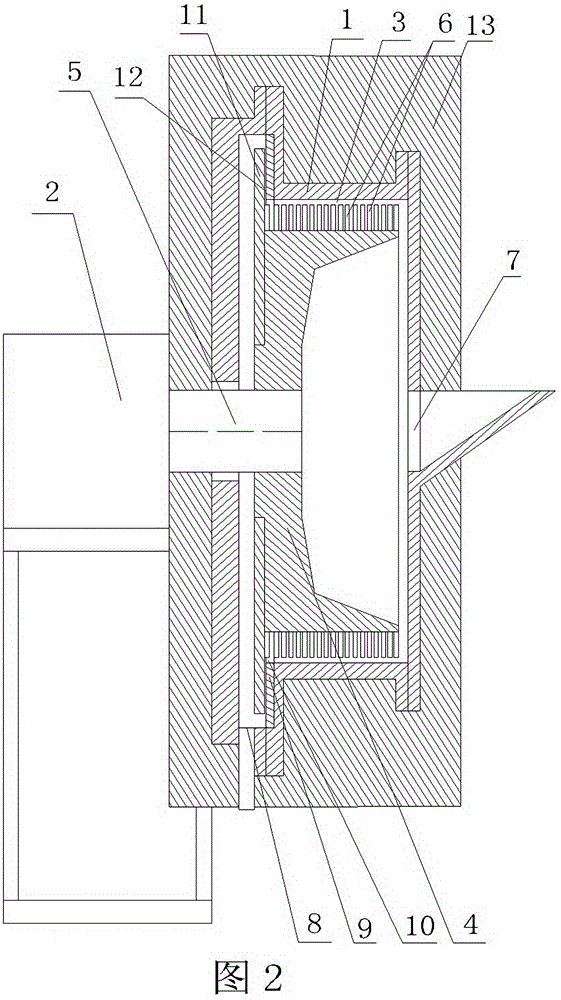

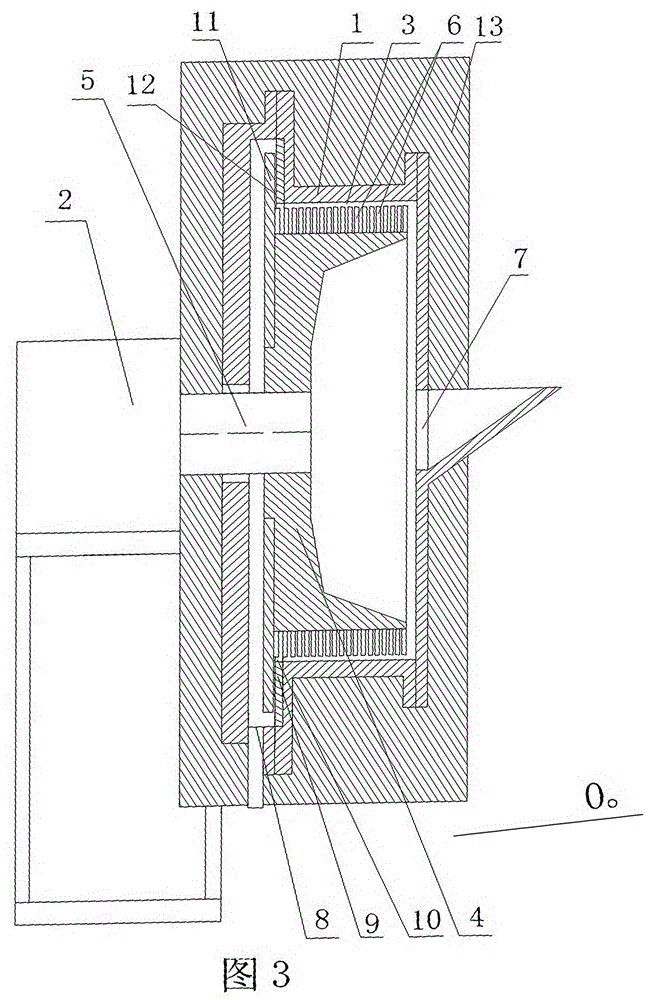

[0026] The main structure of the foam material generator of the present invention includes a housing 1 and a transmission device 2, the transmission device 2 is arranged on the housing 1, a housing chamber 3 is arranged in the housing 1, and a booster stirring booster stirring foaming wheel is arranged in the housing chamber 3 4. The transmission shaft 5 of the transmission device 2 is connected to the booster stirring booster stirring foaming wheel 4, and a plurality of booster stirring bodies 6 are arranged on the booster stirring booster stirring foaming wheel 4, and the windward side of the booster stirring body 6 is connected to the The cross-section of the pressurized stirring and foaming wheel 4 is inclined at an axial direction. One end of the housing cavity 3 is provided with a housing cavity inlet 7, the other end of the housing cavity 3 is provided with a housing cavity outlet 8, and the inner wall of the housing cavity 3 close to the housing cavity outlet 8 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com