Automatic tassel weaving equipment

An automatic and equipment technology, applied in decorative textiles, textiles and papermaking, etc., can solve the problems of difficult to achieve uniform standards, unstable quality, low work efficiency, etc., to achieve good clamping and fixing effect, low labor cost, work Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

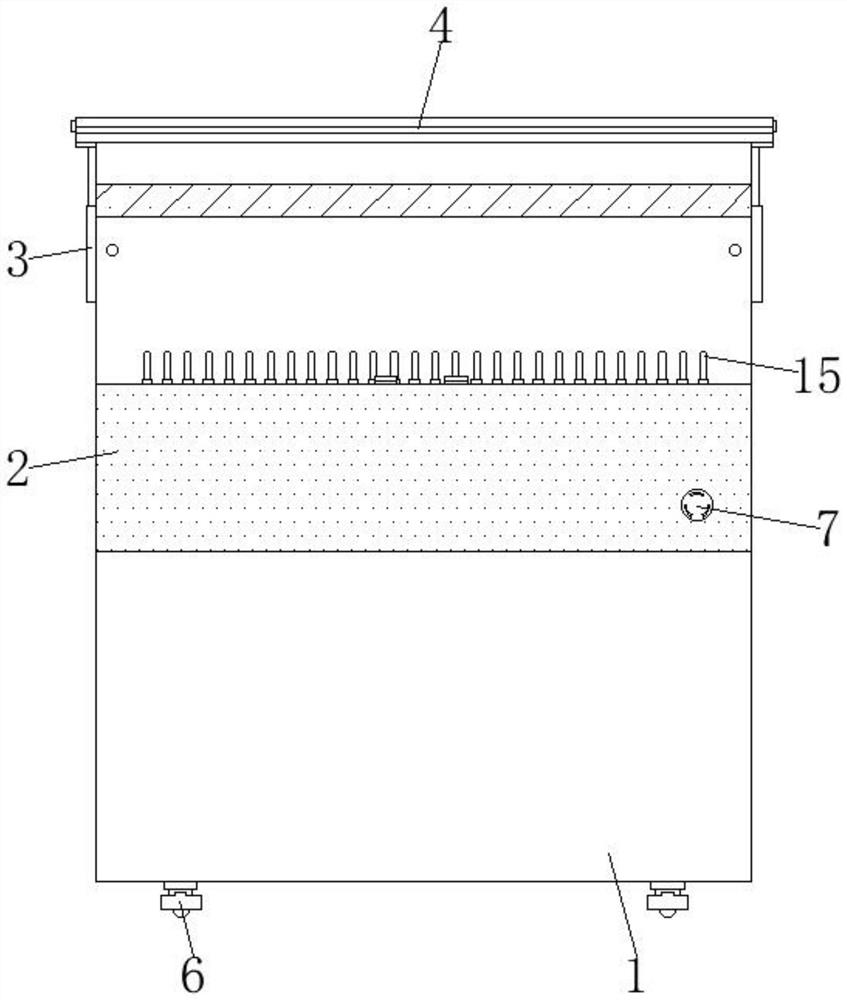

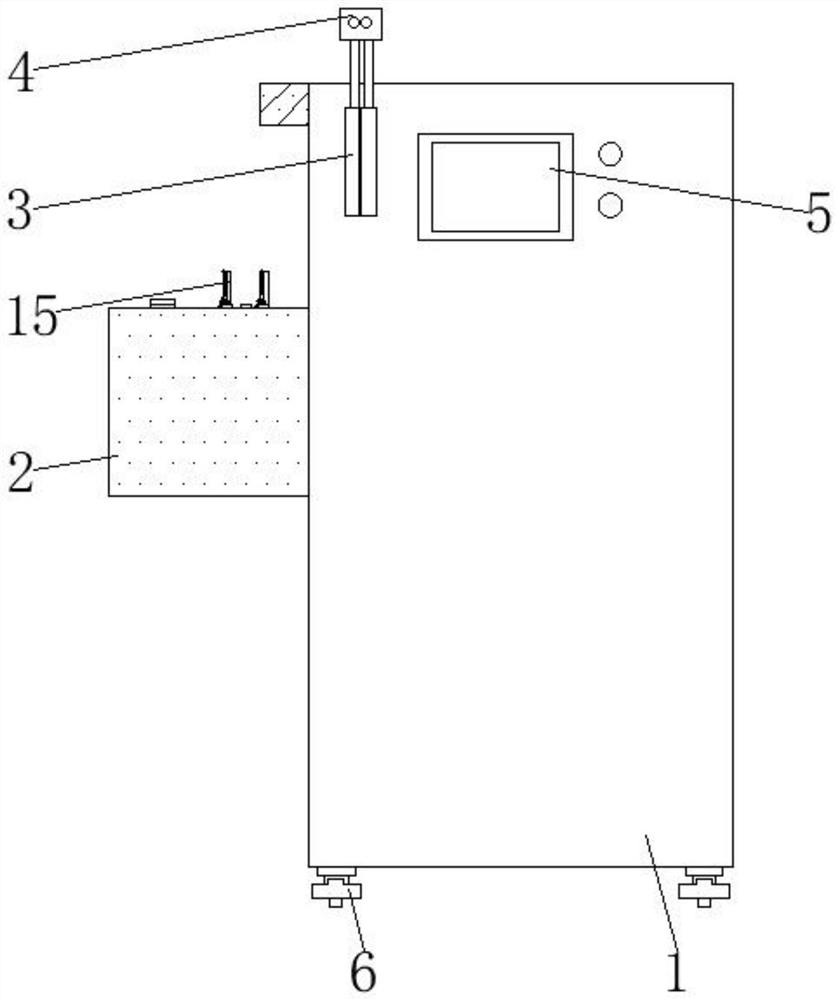

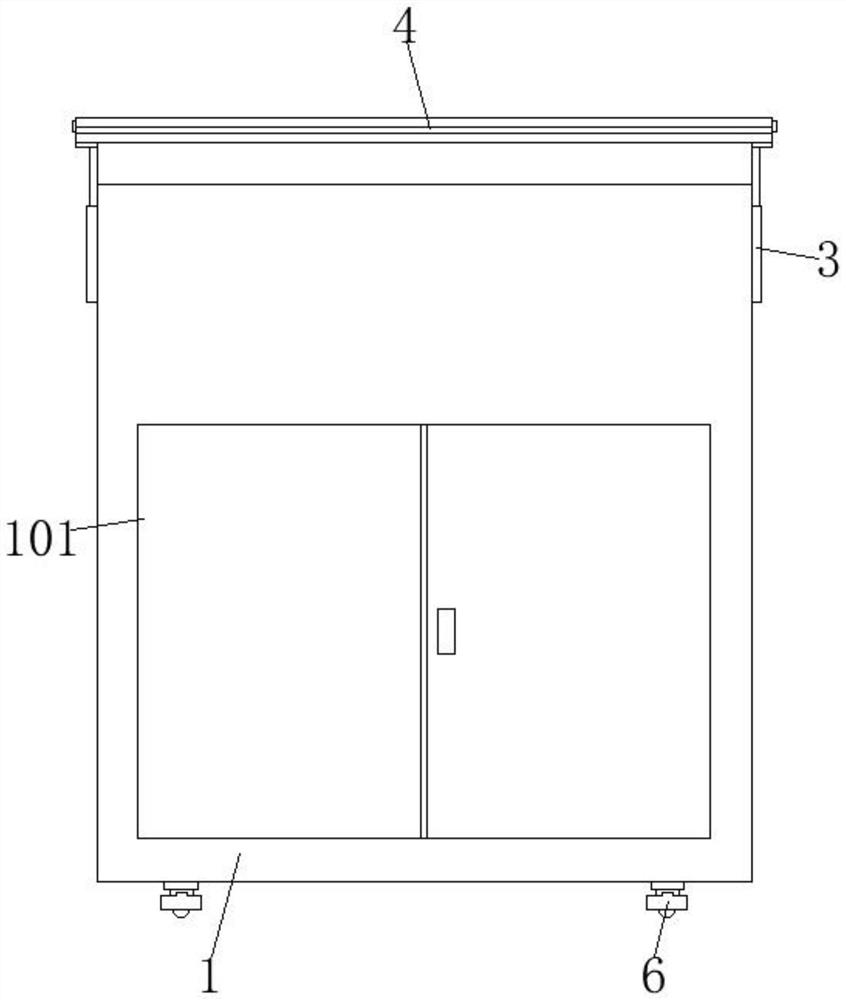

[0022] Such as figure 1 , 2 , 3, 4, and 5, a kind of automatic tassel weaving equipment includes a main body 1 and a chassis 2, the front ends of the side walls on the left and right sides of the main body 1 are fixed and symmetrically installed with a first cylinder 3, and the top piston end of the first cylinder 3 is connected to There is a pressure roller 4, the top of the right side wall of the main body 1 is fixed with a control panel 5, the four corners of the bottom of the main body 1 are fixed with universal wheels 6, the back of the main body 1 is also provided with a control door 101, and the outer wall of the front of the cabinet 2 An emergency stop key 7 is provided on one side of the chassis 2, and an installation groove 8 is fixedly provided on the inner top of the chassis 2. The front side wall of the installation groove 8 is fixedly provided with a chute 9, and the rear end bottom wall of the installation groove 8 is fixedly installed with a second Cylinder 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com