Novel bell-jar furnace

A bell jar furnace and a new type of technology, applied in the field of bell jar furnaces, can solve the problems of unspecified lifting parameters of scissor hydraulic lifting platform, low efficiency, high height, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

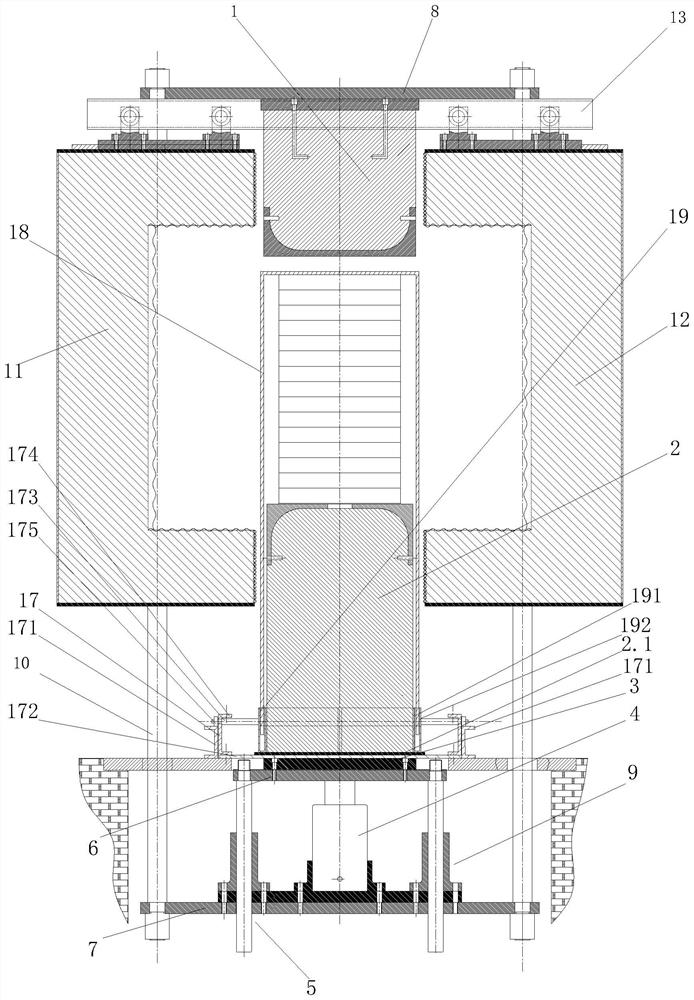

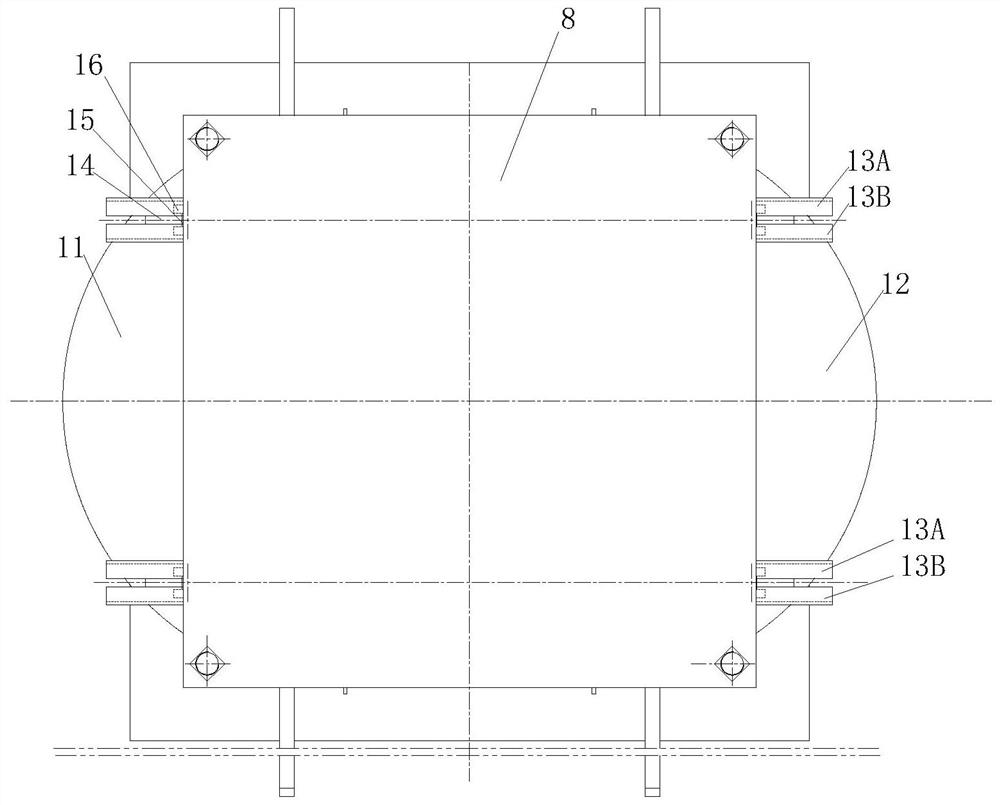

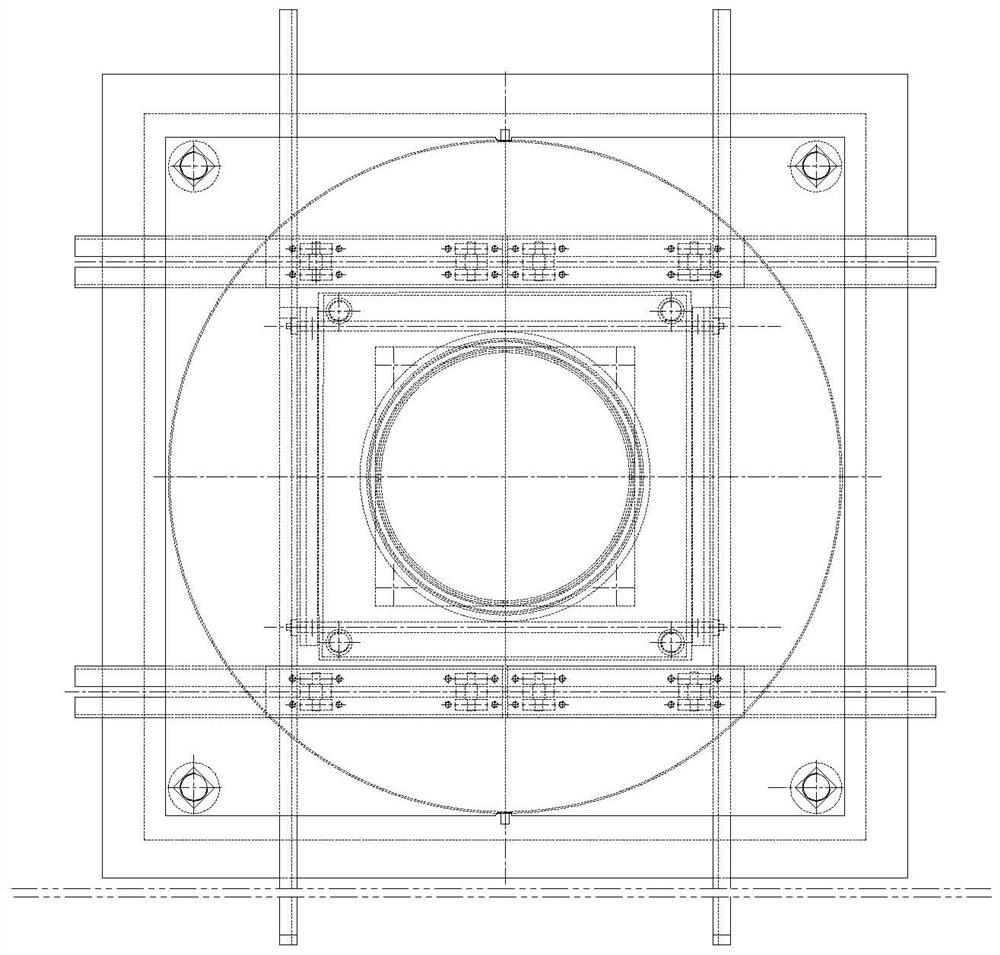

[0022] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes an upper furnace 1, a lower furnace 2, a lower furnace support 3, a lifting device 4, a guide column 5, a lifting frame upper plate 6, a lifting frame lower plate 7, an upper furnace mounting plate 8, Guide post guide seat 9, column 10, left half furnace body 11, right half furnace body 12, furnace body track 13, furnace body installation frame. Described furnace body installation frame comprises hanger 14, wheel shaft 15, roller 16, lower furnace Dun level pushing mechanism 17. The outer ends of the left half furnace body 11 and the right half furnace body 12 are semi-cylindrical, and the upper and lower ends are respectively semi-circular. Lifting device 4 can be a kind of in multiple lifting devices such as hydraulic lifting device, air pressure lifting device, gear lifting device, and their structure and working principle all are known technologies, do not repeat them here;

[0023]...

Embodiment 2

[0031] The difference between the second embodiment and the first embodiment is that the main body of the furnace track 13 in the second embodiment is in a "concave" shape, and the upper ends of the front and rear side walls of the furnace track 13 are each provided with a number of connecting ears and through these connecting ears It is detachably connected with the upper furnace mounting plate 8, and the bottom of the furnace track 13 is provided with a left-right groove to form a section of the corresponding interval between the middle rail body 13A and the rail body 2 13B in Embodiment 1 for installing the furnace. body mount.

Embodiment 3

[0033] The difference between the third embodiment and the first embodiment is that the wheel track 13 and the upper furnace mounting plate 8 in the third embodiment are the same body, and the corresponding parts of the front and rear ends of the corresponding upper furnace mounting plate 8 are respectively provided with Two grooves going left and right; the upper end of the hanger 14 is located at the upper end of the upper furnace mounting plate 8, and the front and rear ends of each wheel shaft 15 are respectively provided with a roller 16 that is respectively rolled and supported on the upper furnace mounting plate 8. Preferably, the upper furnace mounting plate 8 is also detachably connected with the corresponding dust cover to prevent falling on the moving track of the rollers. The specific structural details are not repeated here because they are simple techniques.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com