Equipment production efficiency monitoring method and system, electronic equipment and storage medium

A production efficiency and monitoring system technology, applied in the field of automation, can solve the problems of reducing the production efficiency of the production line and equipment utilization, low production efficiency, and equipment that cannot be detected in time, and achieve the effect of improving work efficiency and capacity utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

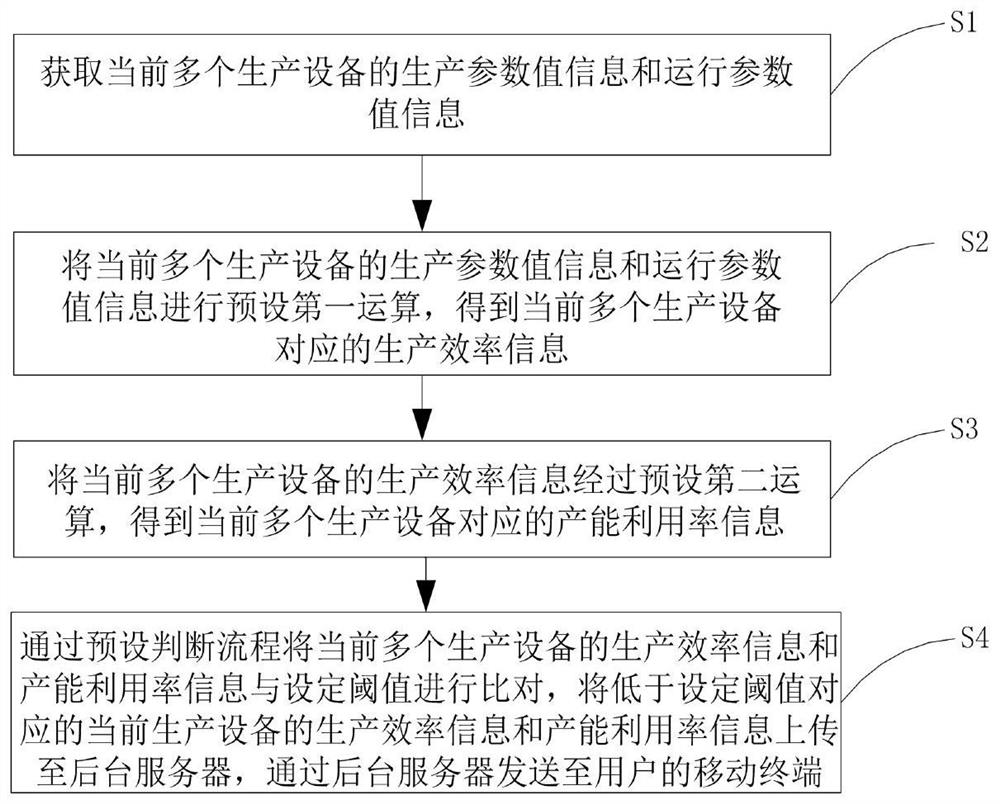

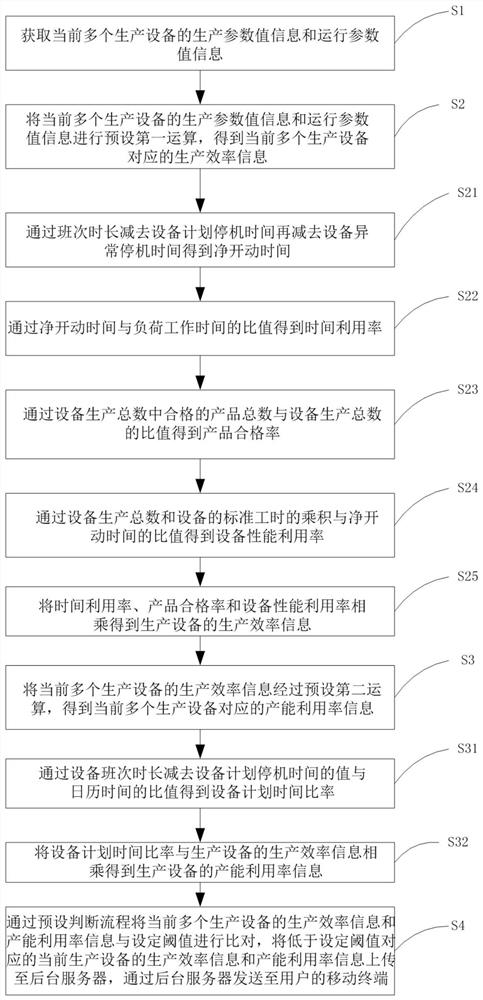

[0050] This embodiment provides a monitoring method for equipment production efficiency, such as figure 1 and figure 2 As shown, the method includes the steps of:

[0051] S1: Obtain production parameter value information and operating parameter value information of multiple current production equipment;

[0052] S2: Perform a preset first operation on the production parameter value information and operating parameter value information of the current multiple production equipment to obtain the production efficiency information corresponding to the current multiple production equipment;

[0053] S3: The production efficiency information of the current multiple production equipment is subjected to the preset second calculation to obtain the capacity utilization rate information corresponding to the current multiple production equipment;

[0054]S4: Through the preset judgment process, compare the production efficiency information and capacity utilization rate information of m...

Embodiment 2

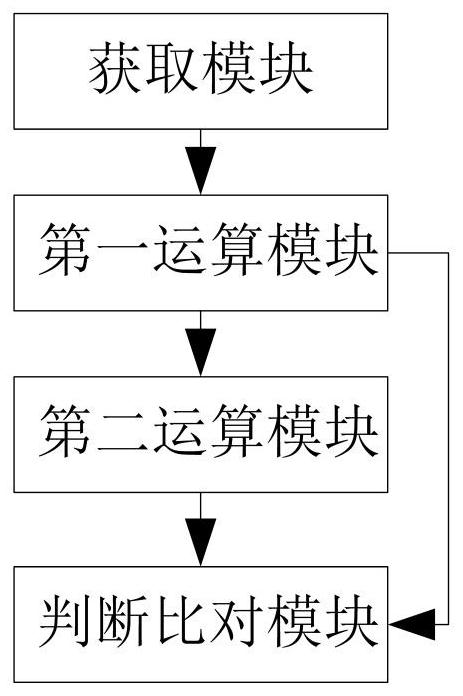

[0074] This embodiment provides a monitoring system for equipment production efficiency, such as image 3 and Figure 4 As shown, the system includes:

[0075] Obtaining module: used to obtain the production parameter value information and operation parameter value information of multiple current production equipment;

[0076] The first calculation module: used to perform the preset first calculation on the production parameter value information and the operation parameter value information of the current multiple production equipment, and obtain the production efficiency information corresponding to the current multiple production equipment;

[0077] The second calculation module: used to process the production efficiency information of the current multiple production equipment through the preset second calculation to obtain the capacity utilization rate information corresponding to the current multiple production equipment;

[0078] Judgment and comparison module: compare ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com