Sealing structure of natural ester insulating oil transformer

A technology of sealing structure and insulating oil, applied in transformer/inductor parts, transformer/inductor casing, transformer/inductor coil/winding/connection, etc., can solve the problem of insufficient sealing of transformer outlet box and easy occurrence of gasket Oil leakage, insufficient sealing performance and other problems, to achieve the effect of good sealing performance, sufficient compression, and reduce the risk of oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

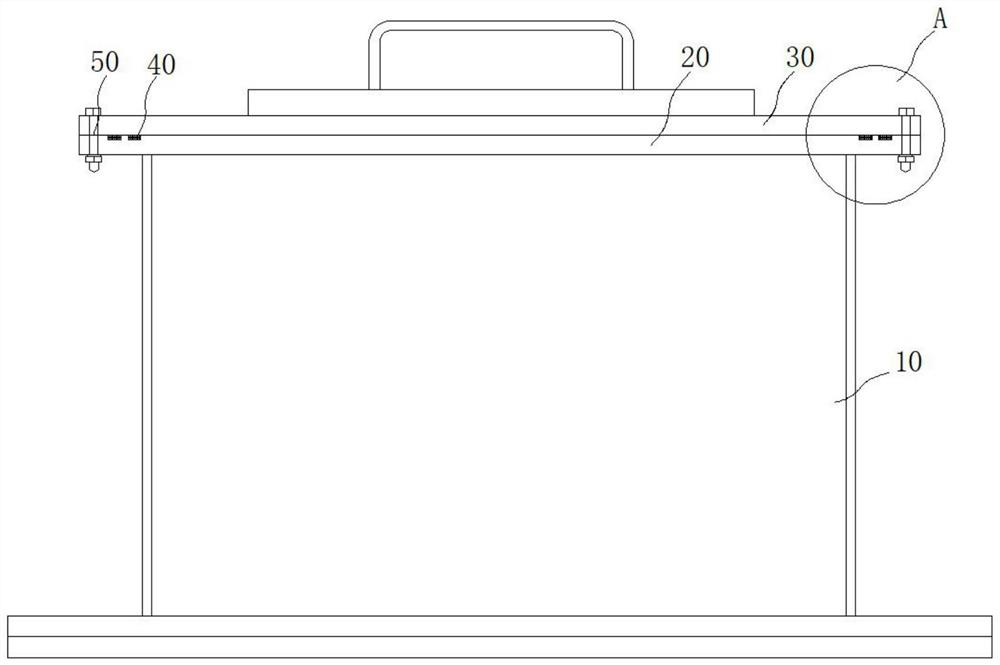

[0024] refer to figure 1 , a natural ester insulating oil transformer sealing structure, including an outlet box 10, an outlet box flange 20 arranged on the top of the outlet box, and a cover plate 30 arranged on the top of the outlet box and used in conjunction with the outlet box flange, and also includes:

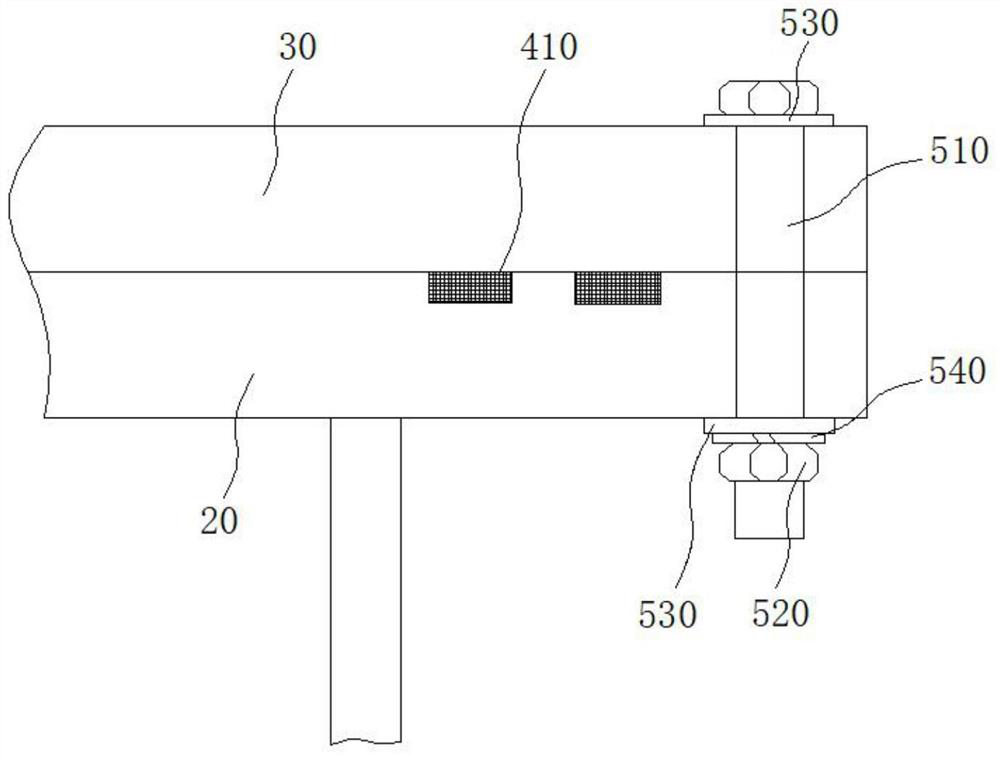

[0025] A sealing assembly 40, the sealing assembly is arranged on the contact surface between the flange of the outlet box and the cover plate; and

[0026] Fastener 50, the fastener is arranged through the flange of the outlet box of the cover plate box, and is used to fix the flange of the outlet box and the cover plate;

[0027] Wherein, the sealing assembly includes at least two sealing gaskets 410 that are in close contact with the cover plate along the flange end surface of the outlet box. In the present invention, a plurality of sealing gaskets are arranged between the flange of the outlet box and the cover plate, and two If it is fixed, multiple sealing gaskets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com