Self-starting permanent magnet auxiliary synchronous reluctance motor rotor and motor

A technology for auxiliary synchronous and reluctance motors, applied in the field of motors, can solve the problems of large demagnetization risk of permanent magnets, poor anti-demagnetization ability of motors, and small coercive force of ferrite, so as to save controller loss and improve resistance Effect of improving demagnetization ability and anti-demagnetization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

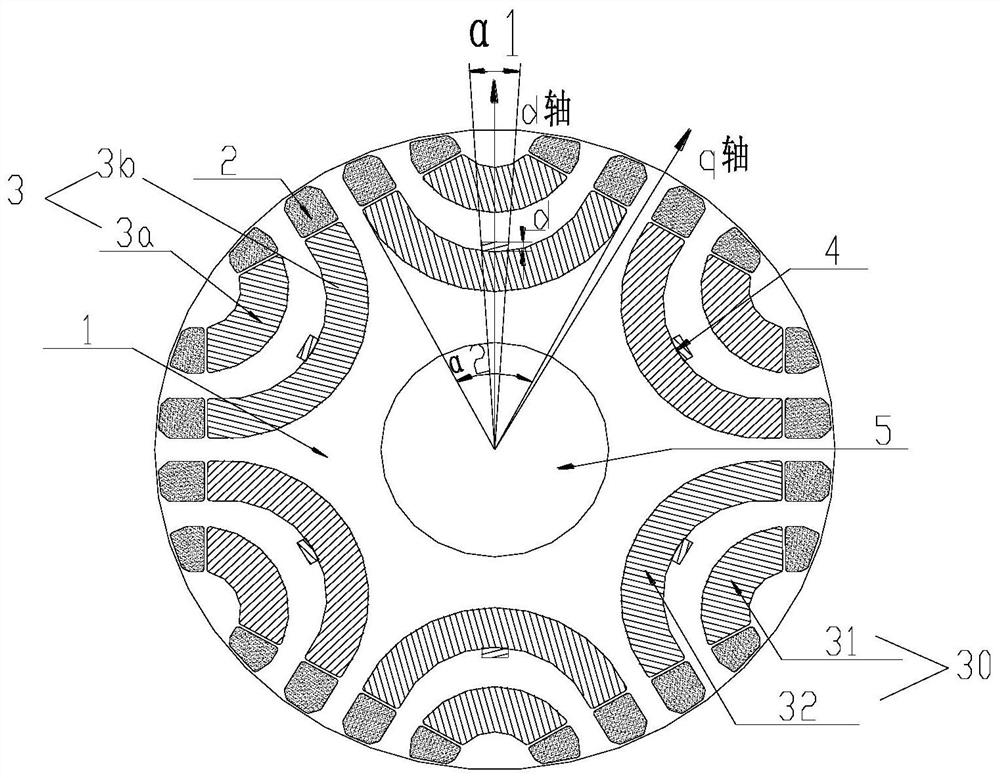

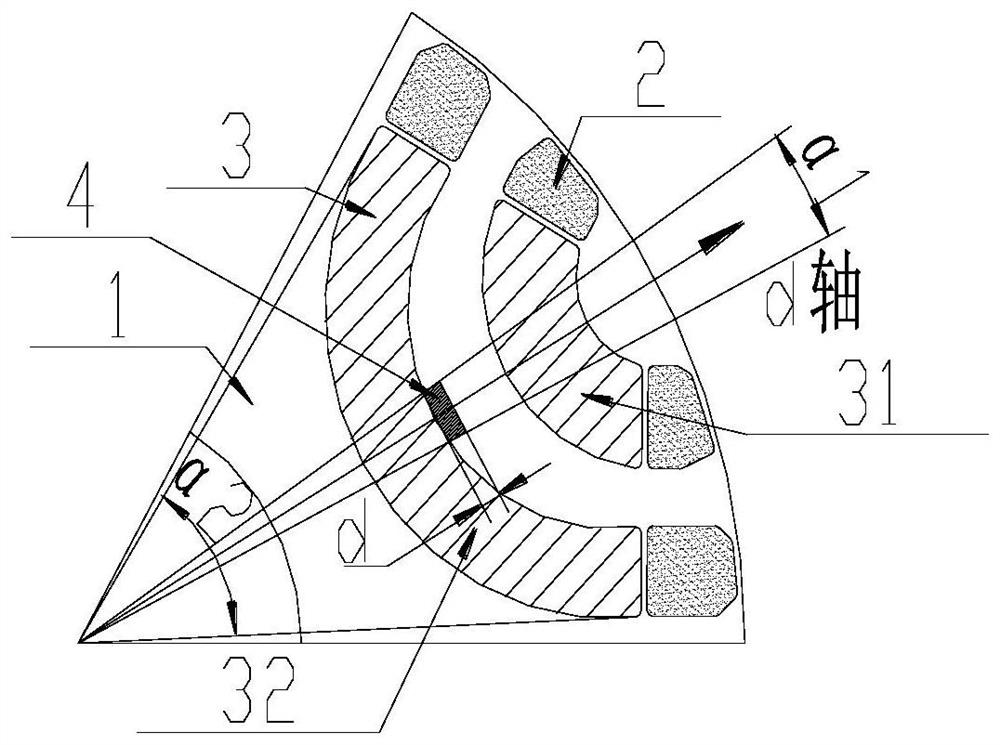

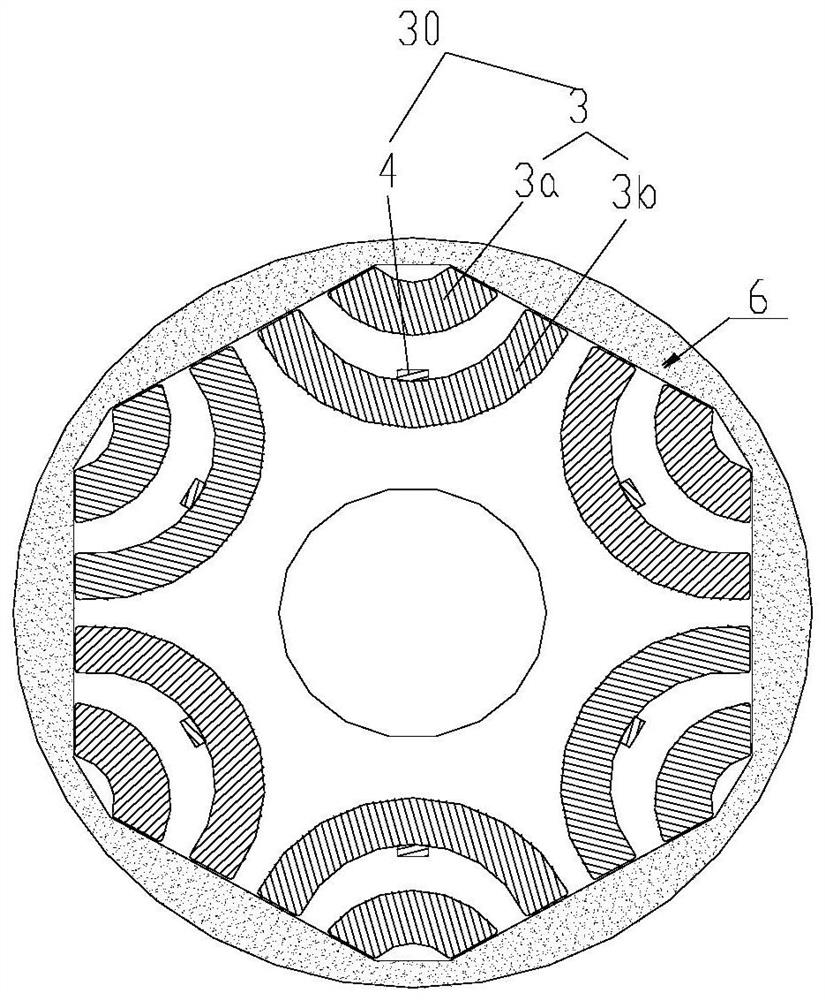

[0026] Such as Figure 1-4 As shown, the present invention provides a self-starting permanent magnet assisted synchronous reluctance motor rotor, which includes a plurality of rotor punches 1, and a plurality of rotor punches 1 are stacked to form a rotor core. There are filling slots 2, permanent magnets 30 and shaft holes 5; the permanent magnets 30 include an outer permanent magnet 31 relatively located on the radially outer side, and an inner permanent magnet 32 relatively located on the radially inner side, and the outer permanent magnet 31 includes the outer layer ferrite 3a, the inner layer permanent magnet 32 includes the inner layer ferrite 3b and NdFeB 4, the NdFeB 4 is located on the d-axis of the motor rotor and the NdFeB 4 is located between the outer layer ferrite 3a and the inner layer ferrite 3b. The NdFeB adopts parallel magnetization, and the magnetization direction is along the radial direction of the rotor.

[0027] In the present invention, an inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com