Extruding machine for aluminum profile

A technology for extrusion presses and aluminum profiles, which is applied in the direction of metal extrusion dies, etc., can solve the problems of increasing equipment costs and large extrusion force, and achieve the effect of reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

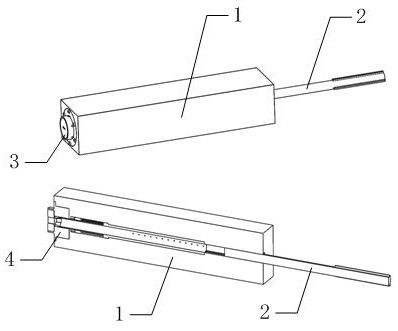

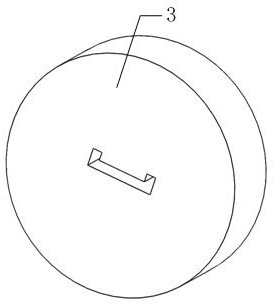

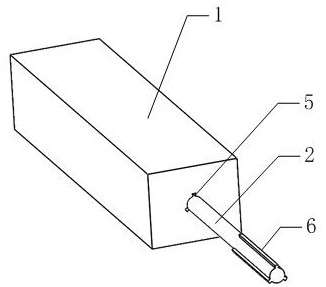

[0072] Embodiment: When using the extrusion machine designed by the present invention, in the initial state, when the locking mechanism 23 is not unlocked, the external threaded area on the upper end of the slide rod 46 is threadedly matched with the internal threaded area on the threaded sleeve 53, and due to the thread The sleeve 53 is installed on the installation housing 10 through the rotation fit of the rotation ring 50 and the rotation ring groove 40, and the thread sleeve 53 slides stationary relative to the installation housing 10 along the axial direction of the slide rod 46, that is, the sliding sleeve 53 is connected with the thread sleeve 53 through thread fit. At this time, the rod 46 also slides still relative to the installation housing 10 along the axial direction of the slide rod 46, that is, the adjustment block 48 installed on the slide rod 46 is stationary, and the adjustment block 48 is locked; in this state, the adjustment block 48 is close to the installa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap