Stirring device

A stirring device and stirring shaft technology, applied in the field of concrete mixing, can solve the problems of low mixing efficiency and high processing difficulty of mixing blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

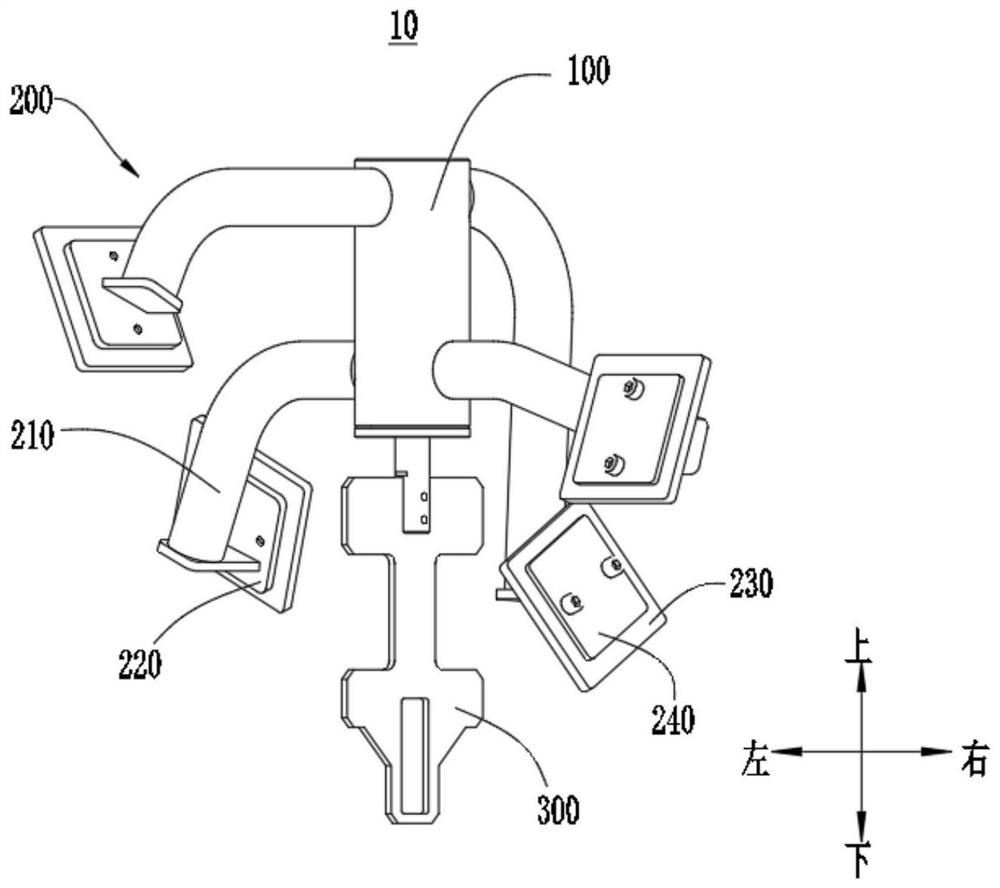

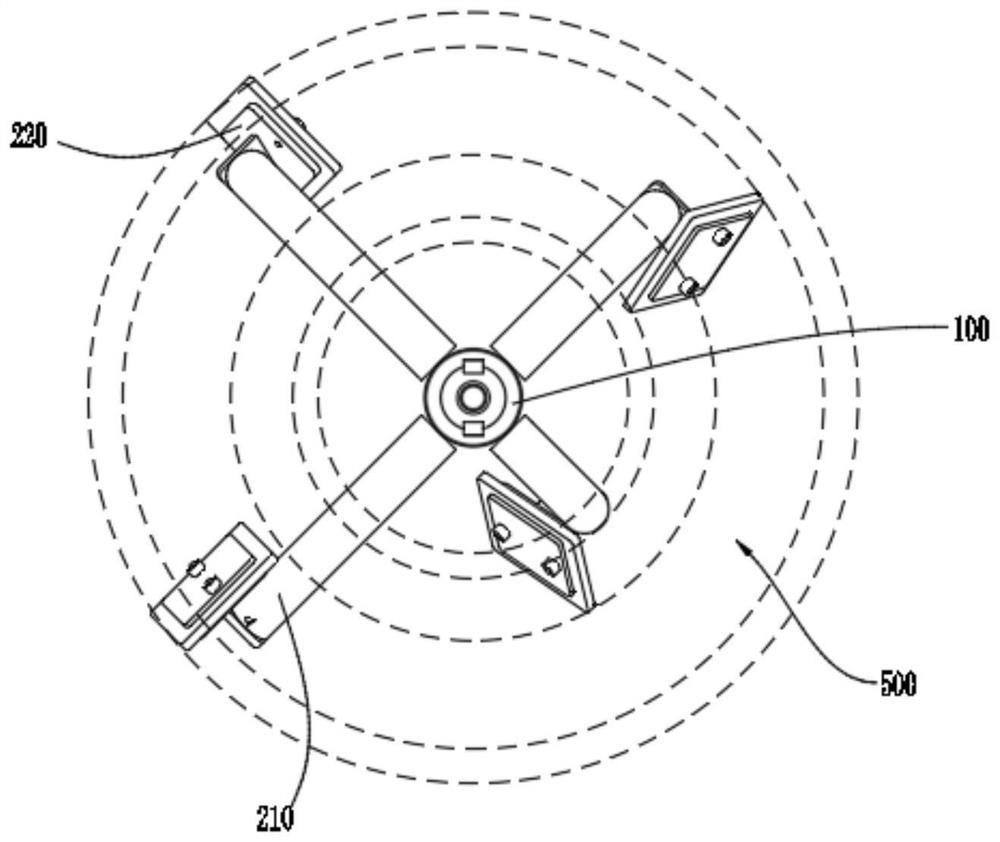

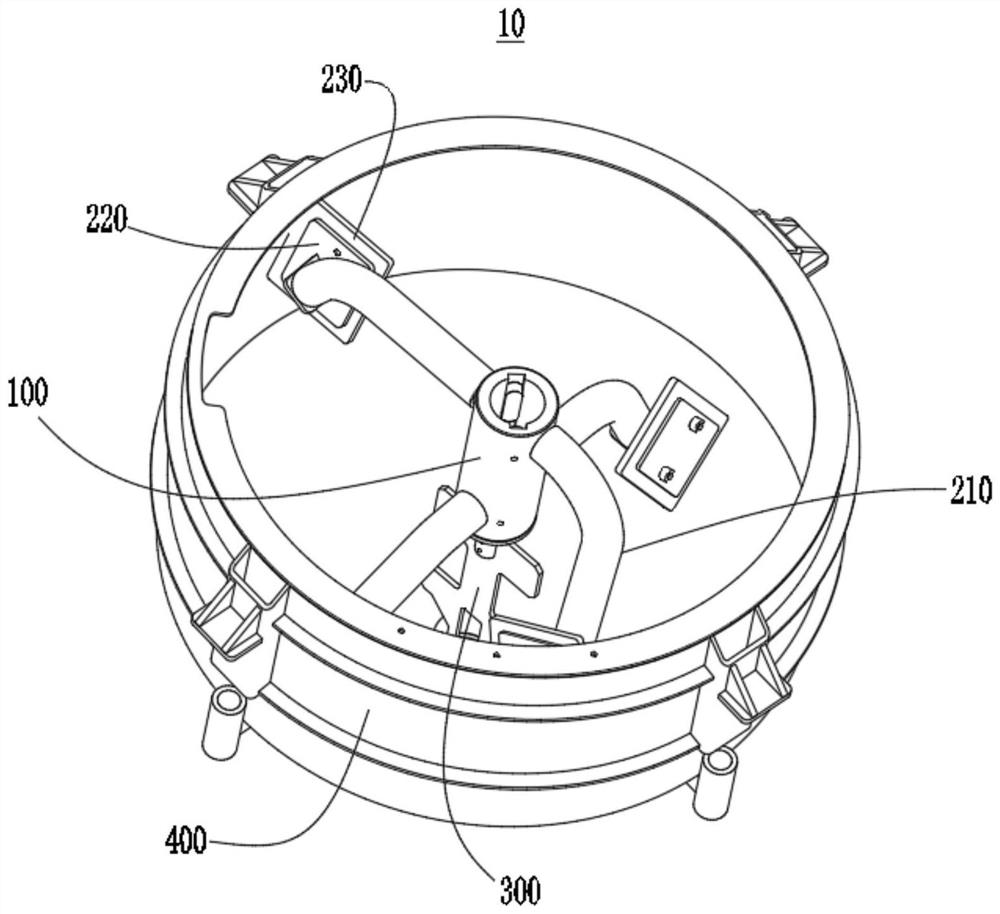

[0026] Please refer to figure 1 , this embodiment provides a stirring device 10 , the stirring device 10 includes a stirring shaft 100 and at least two stirring components 200 . Each stirring assembly 200 includes a first stirring blade 220 and a connecting rod 210 , and the connecting rod 210 connects the stirring shaft 100 and the first stirring blade 220 . At least two first stirring blades 220 are distributed up and down along the axial direction of the stirring shaft 100 . The face of the first stirring blade 220 of the upper floor is along the direction of rotation ( figure 1 From top to bottom, it is counterclockwise) to tilt downward, and the surface of the first stirring blade 220 on the lower floor is along the direction of rotation ( figure 1 Viewed from top to bottom in the counterclockwise direction) upward slope. The stirring device 10 includes a stirring shaft 100 and a stirring assembly 200, and has a simple structure and is easy to manufacture. The first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com