Automatic film blowing and feeding mechanism for sheet stock

An automatic, sheet material technology, applied in the direction of thin material processing, conveyor objects, sending objects, etc., can solve the problem that the production method cannot meet the mass production mode, etc., and achieve the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

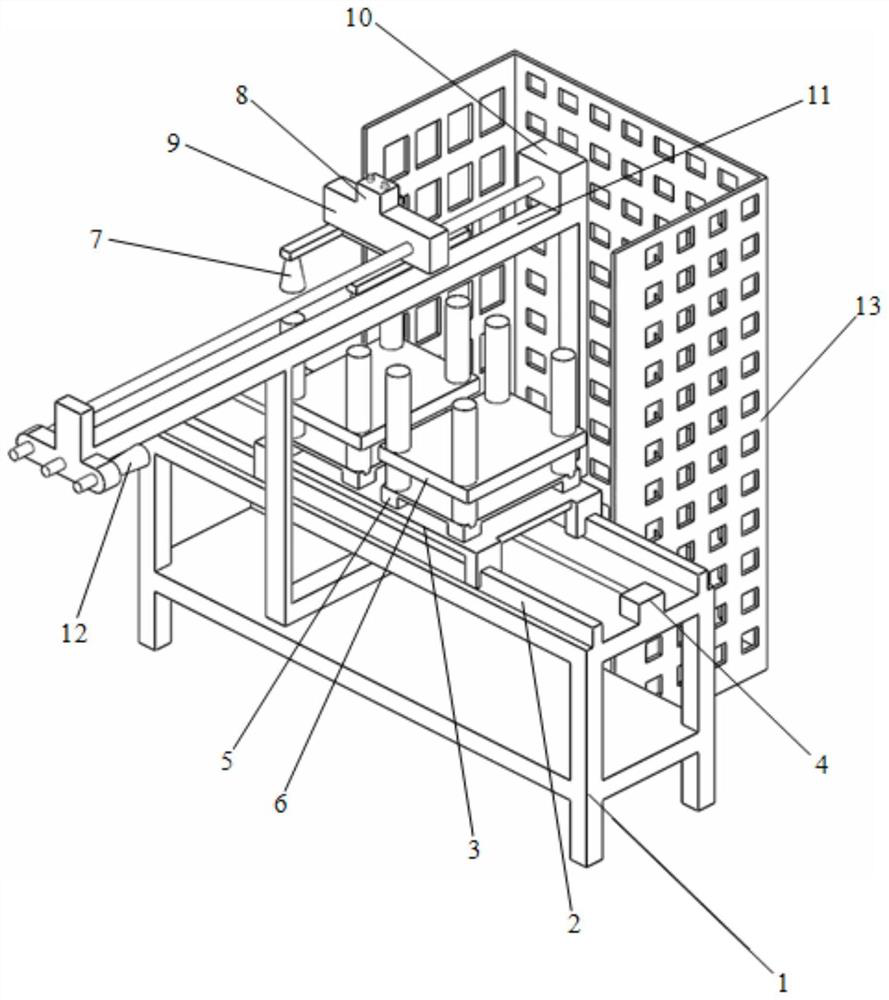

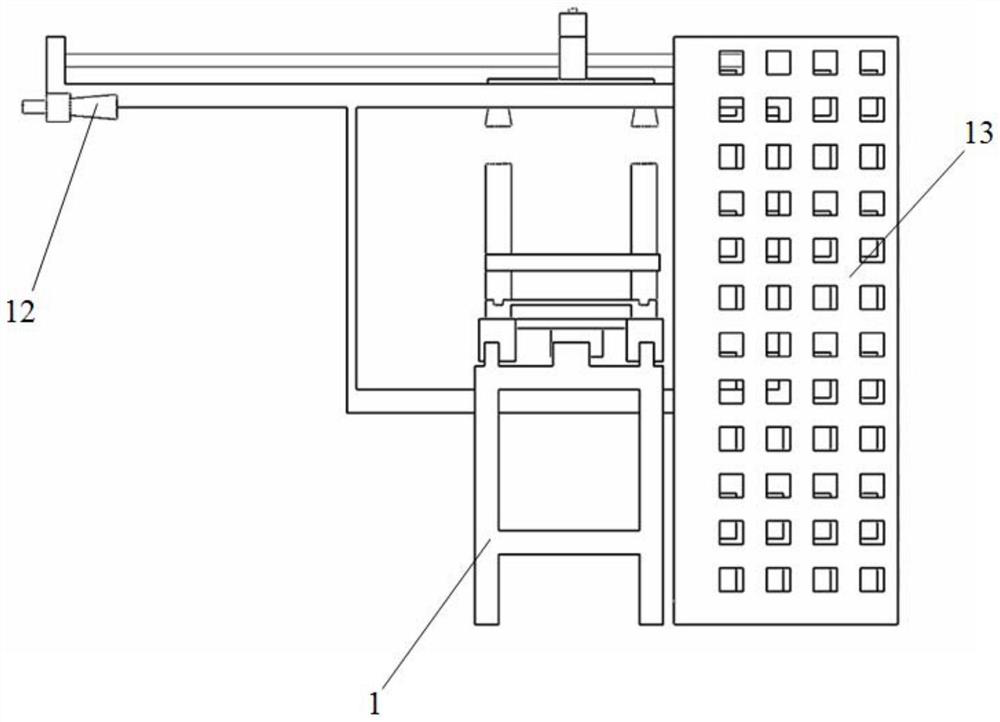

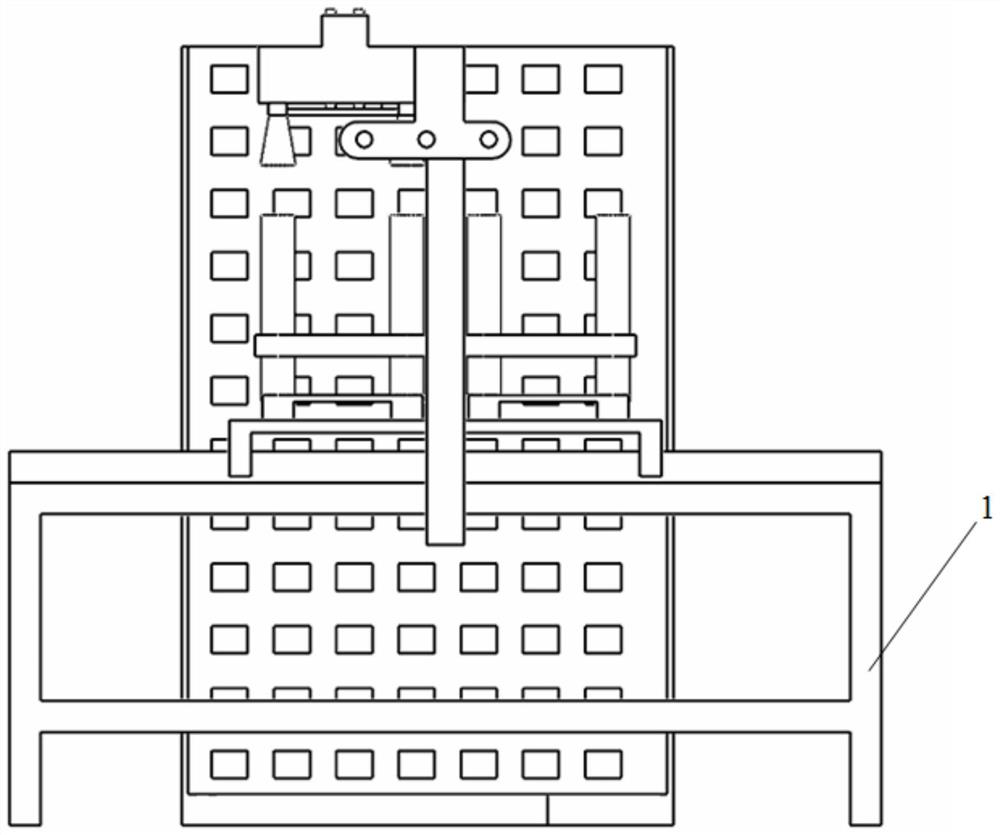

[0012] See details Figure 1-4 Shown: a sheet material automatic blown film feeding mechanism, including a frame 1 and a linear guide rail 2 arranged on the frame 1, a slide plate 3 is movably installed on the linear guide rail 2, the first lead screw The motor 4 is fixed on the frame 1 and connected to the slide plate 3, the second lead screw motor 5 is fixed on the slide plate 3, and the lifting plate 6 is connected to the second lead screw motor 5, placed in the Above the lifting plate 6 is a sucker 7, and the sucker 7 is installed on the cylinder 8, and the cylinder 8 is fixed on the moving arm 9, and the moving arm 9 is installed on the third lead screw motor 10, and the third screw The bar motor 10 is fixed on the beam 11, the beam 11 is fixed on the frame 1, an air nozzle 12 is arranged at one end of the beam 11, and a mesh storage box 13 is arranged on the side of the frame 1 .

[0013] The present invention is an automatic blown film feeding mechanism for sheet mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com