Composite armor structure with inverted cone, manufacturing method and mounting method

A cone and armor technology, applied in the field of composite armor structure, can solve the problems of overall protection of unfavorable structures, and achieve the effect of reducing damage to the wound surface, convenient use, and smooth structure surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

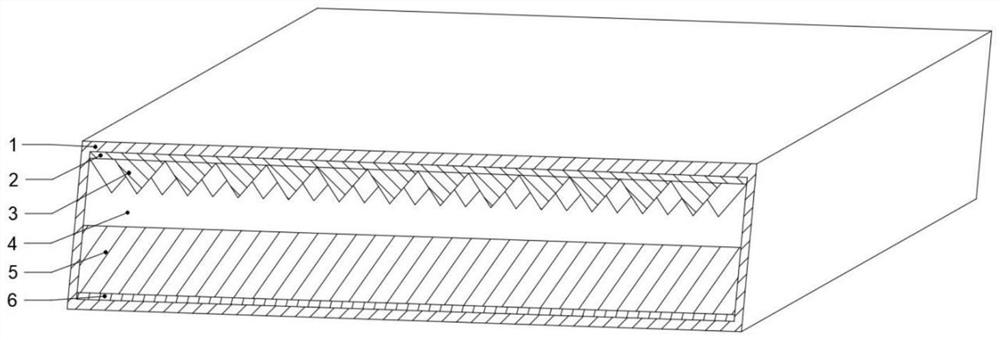

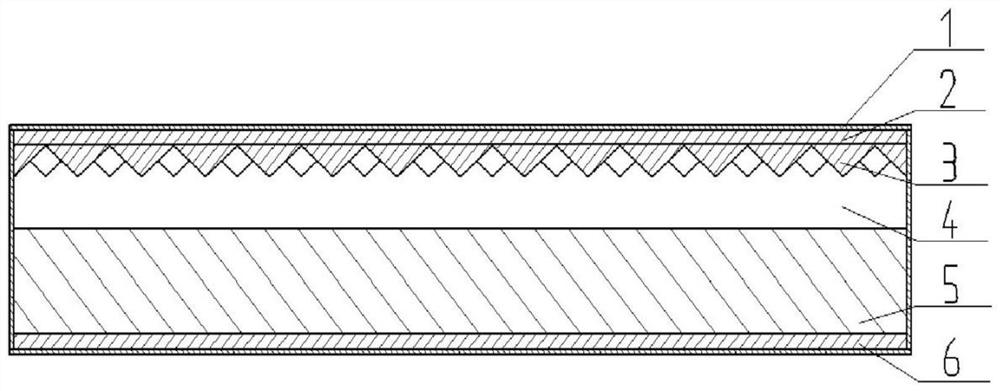

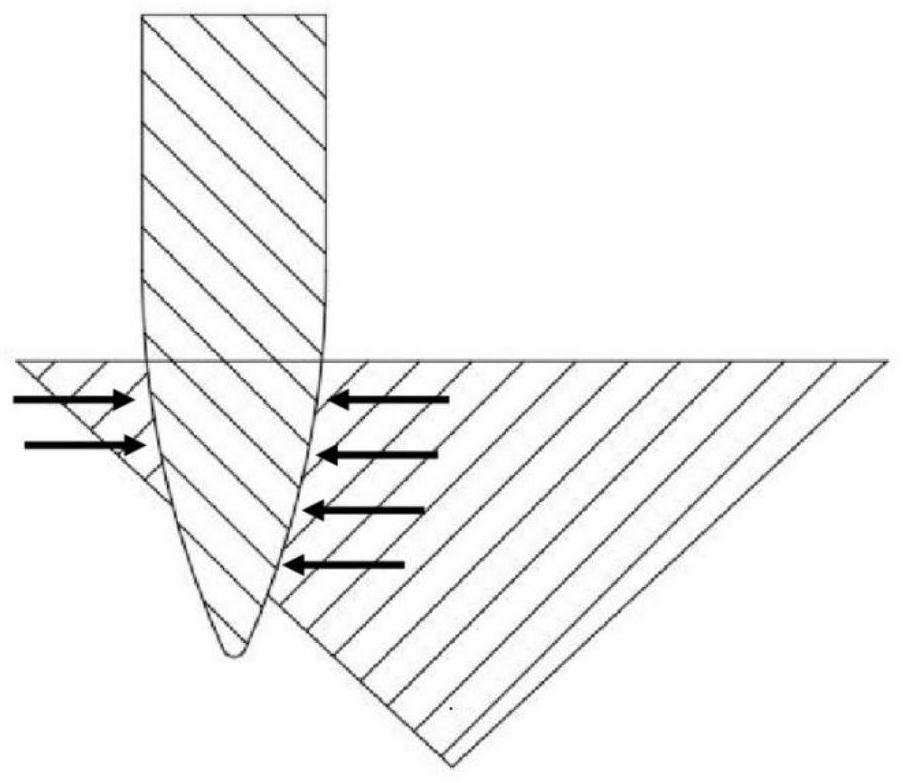

[0052] Such as figure 1 with figure 2 As shown, the composite armor structure with an inverted cone in this embodiment 1 includes a packaging shell 1, an upper panel 2, a cone 3, a gap layer 4, a kinetic energy absorbing layer 5 and a lower panel 6, such as Figure 4 As shown, the cones 3 are quadrangular pyramids, the rows of the cones 3 are misplaced, and the upper panel 2 and the cones 3 form an integrated structure through mold casting. The kinetic energy absorbing layer 5 is embedded in the package shell by the finished product, the connection mode of the upper panel 2 and the package shell 1, the connection mode of the kinetic energy absorbing layer 5 and the lower panel 6, and the connection mode of the lower panel and the package shell 1 can be glued and sealed in the package shell 1 The inner cavity fits into the groove and is limited by the first stopper 102 and the second stopper 103, so that the unit structures of the armor structure are combined to form a whole....

Embodiment 2

[0059] Such as figure 2 with Figure 4 As shown, the composite armor structure with an inverted cone in this embodiment 2 includes a package shell 1, an upper panel 2, a cone 3, a gap layer 4, a kinetic energy absorbing layer 5 and a lower panel 6, wherein the cone is a square pyramid, The cones 3 are misplaced between rows, and the upper panel 2 and the cones 3 form an integrated structure through mold casting. The kinetic energy absorbing layer 5 is embedded in the package shell by the finished product, the connection mode of the upper panel 2 and the package shell 1, the connection mode of the kinetic energy absorbing layer 5 and the lower panel 6, and the connection mode of the lower panel and the package shell 1 can be glued and sealed in the package shell 1 The inner cavity fits into the groove and is limited by the first stopper 102 and the second stopper 103, so that the unit structures of the armor structure are combined to form a whole.

[0060] The package shell ...

Embodiment 3

[0062] Such as figure 2 with Figure 5 As shown, the composite armor structure with an inverted cone in this embodiment 3 includes a packaging shell 1, an upper panel 2, a cone 3, a gap layer 4, a kinetic energy absorbing layer 5 and a lower panel 6, wherein the cone is a cone, and the cone The bodies 3 are misplaced between rows, and the cones 3 are formed by machining on the surface of the upper panel 2 . The kinetic energy absorbing layer 5 is embedded in the package shell by the finished product, the connection mode of the upper panel 2 and the package shell 1, the connection mode of the kinetic energy absorbing layer 5 and the lower panel 6, and the connection mode of the lower panel and the package shell 1 can be glued and sealed in the package shell 1 The inner cavity fits into the groove and is limited by the first stopper 102 and the second stopper 103, so that the unit structures of the armor structure are combined to form a whole.

[0063] Among them, the packagi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com