Method for designing blast wall with multiplayer composite structure

A multi-layer composite and design method technology, applied to walls, building components, building structures, etc., to achieve the effects of reducing damage and personal injury, low cost, and scientific design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The design method and specific implementation steps of the multi-layer composite explosion-proof wall structure are described in detail below in conjunction with the technical scheme and accompanying drawings.

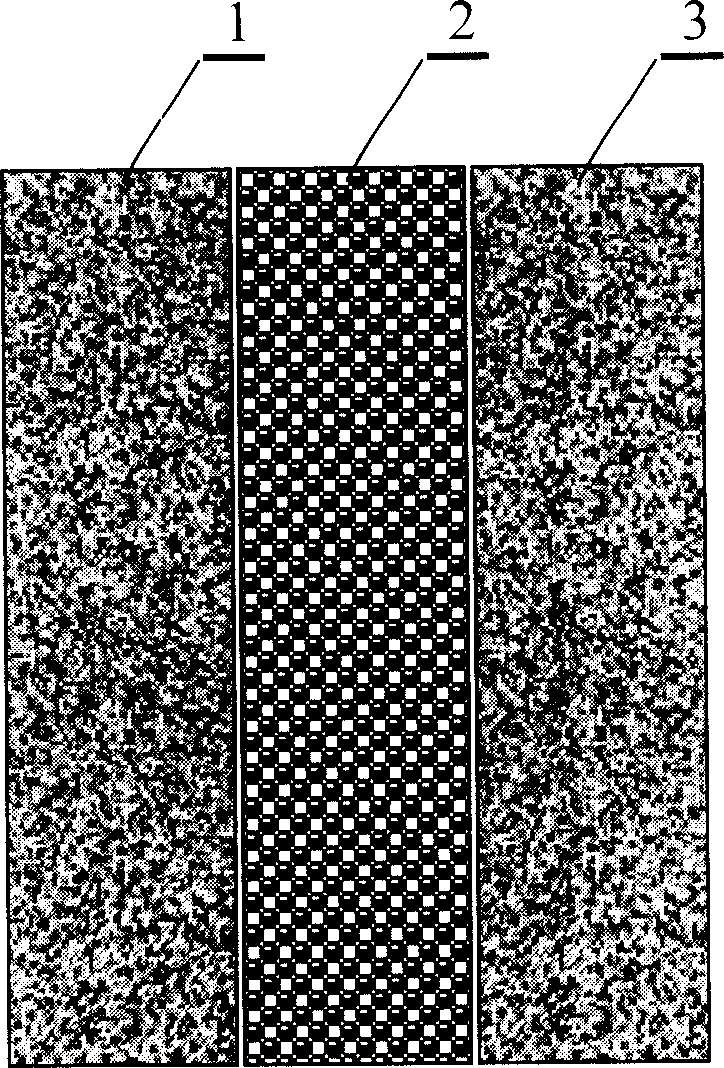

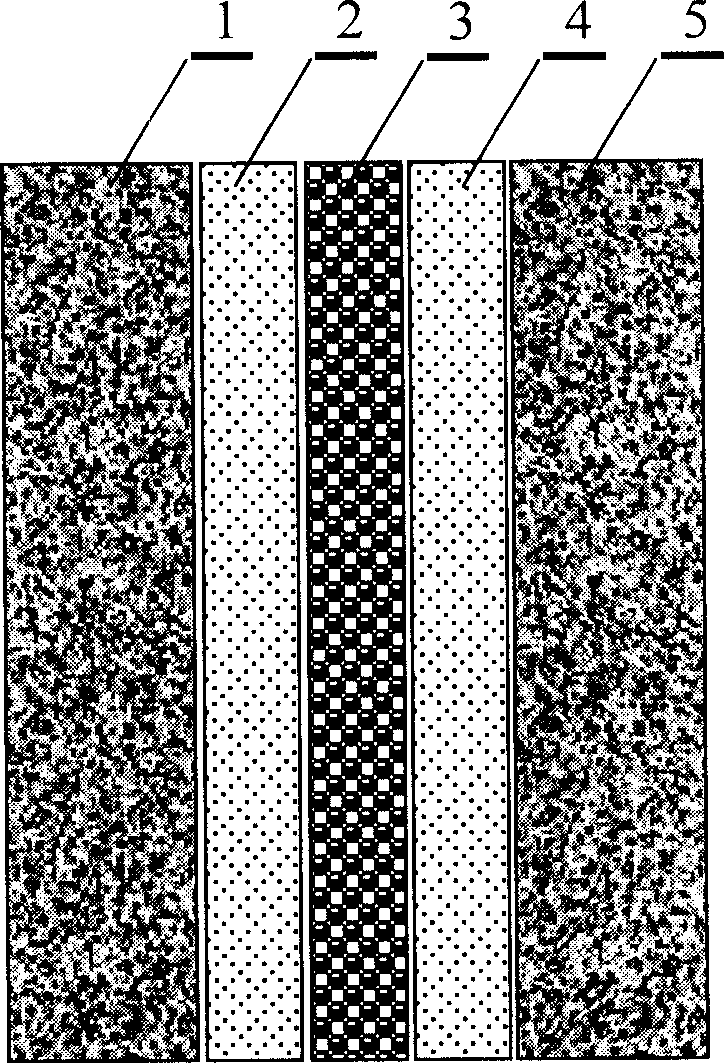

[0011] According to the design requirement that the explosion-proof wall can withstand the blast impact energy level, and based on the theoretical calculation and experimental test of the explosion impact, the parameters of the material, number of layers and thickness ratio of each layer of the multi-layer explosion-proof wall are determined, and the structure is optimized. For near-field explosion events within a radius of 20 meters from the explosion center of TNT explosives less than 100 kg, concrete-porous material-concrete three-layer explosion-proof wall structure can be selected, and the porous material layer should be rigid porous polyurethane with a density of 200-500Kg. m -3 Between, the design thickness is 50% of the entire wall size. For explosives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com