Fatigue test device for simulating bolt connection opening and closing effect

A technology for fatigue testing and bolts, which is applied in the field of fatigue testing devices for simulating the opening and closing effect of bolt connections, can solve problems such as single load direction and inability to truly simulate the stress state of bolts, and achieve improved work efficiency, economical and convenient fatigue tests, and overall The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

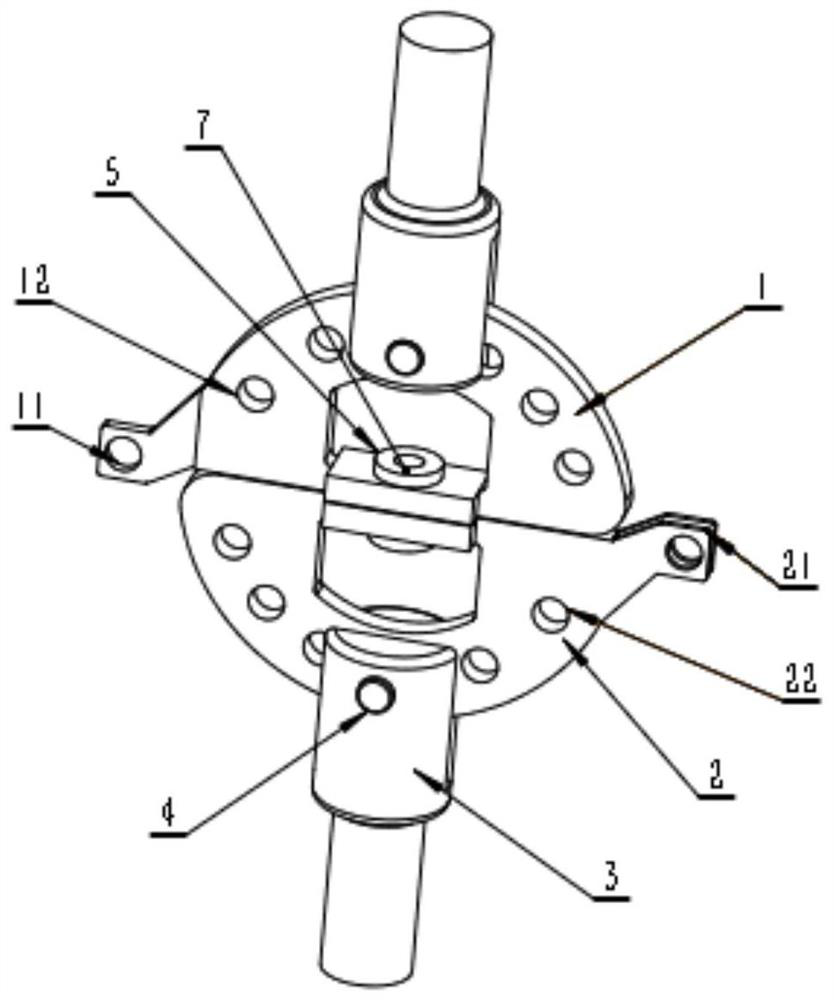

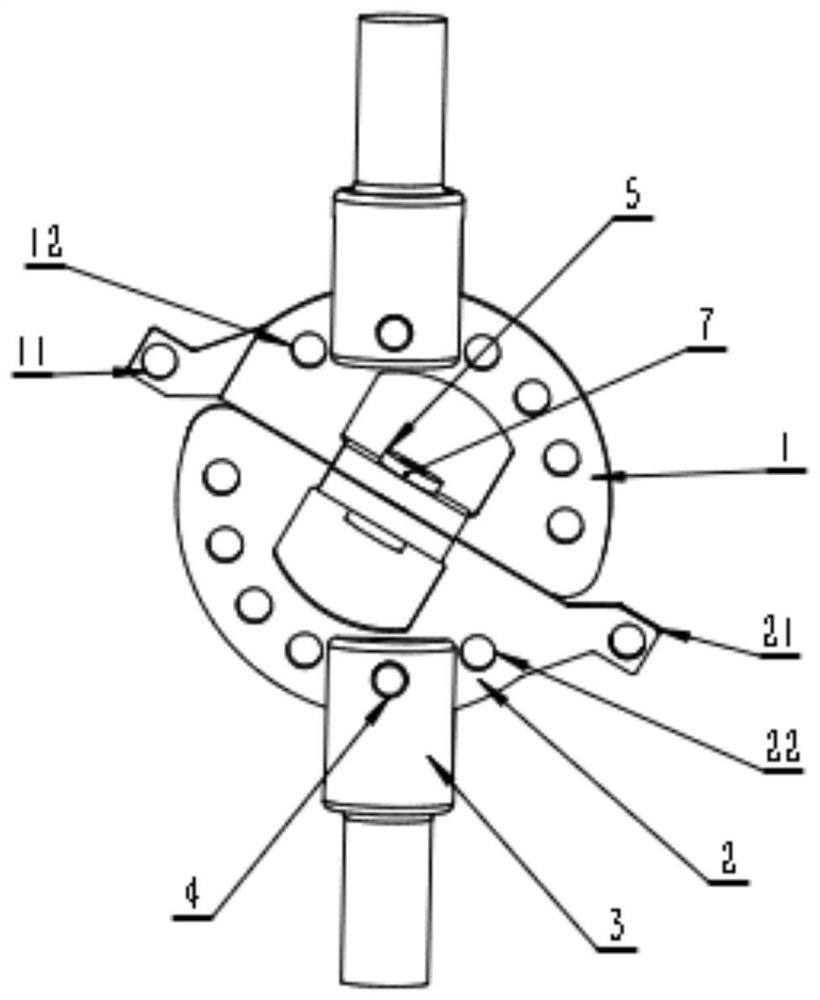

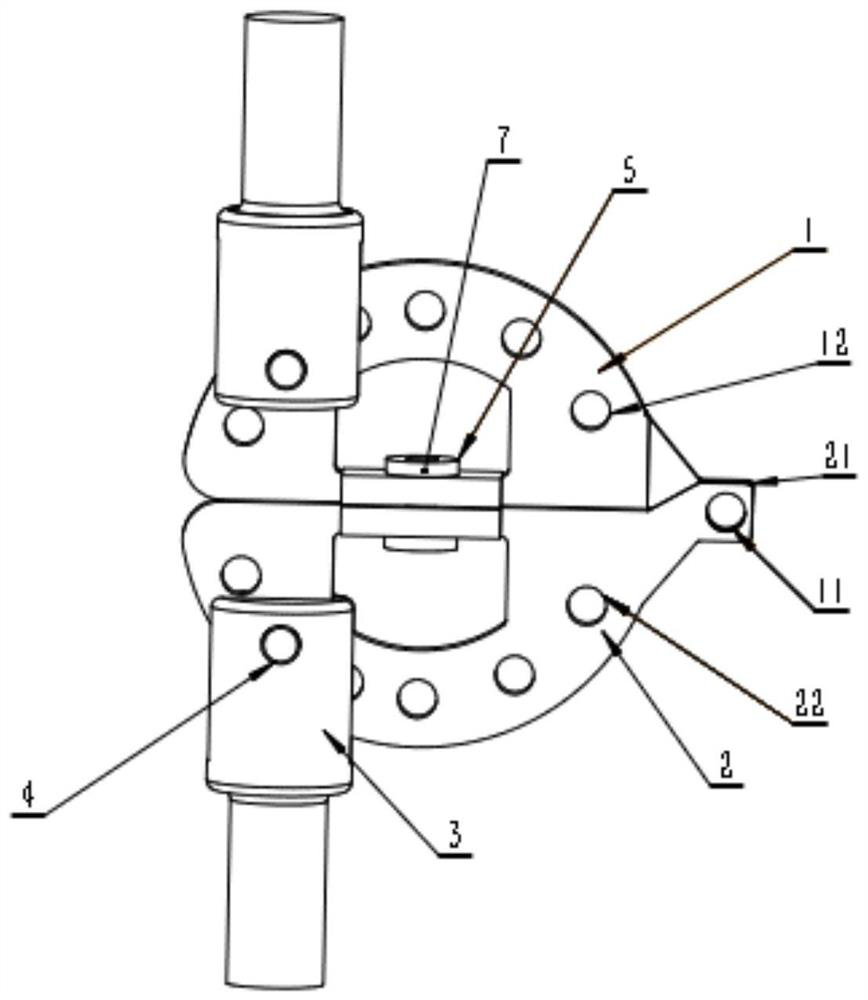

[0020] A fatigue test device for simulating the opening and closing effect of bolted joints, such as Figure 1-5 As shown, the fatigue test device for simulating the opening and closing effect of bolts includes two parts: the upper force plate 1 and the lower force plate 2 . Wherein there are 0°, 30°, 60°, 90°, 112.5°, 135° and 157.5° ( image 3 The positioning hole A12 in the sequence from right to left in the center), the position of the 0° positioning hole adopts a single lifting lug 11, and the center of the circle of the upper force plate 1 is opened with a positioning hole B13; the lower force plate 2 is also opened with 7 kinds of corresponding angles locating hole C22, and the 0° locating hole position adopts symmetrical double lugs 21, and the center of circle of the lower power transmission plate 2 has a locating hole D23. The middle part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com