Low TVOC flame retardant polyurethane spray foam system

A polyurethane foam and spray foam technology, applied in the field of polyurethane spray foam and its preparation, low TVOC flame retardant polyurethane spray foam system, can solve the problems of insufficient mixing, low processing efficiency, no mention of spray processing problems, etc., reaching TVOC value low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

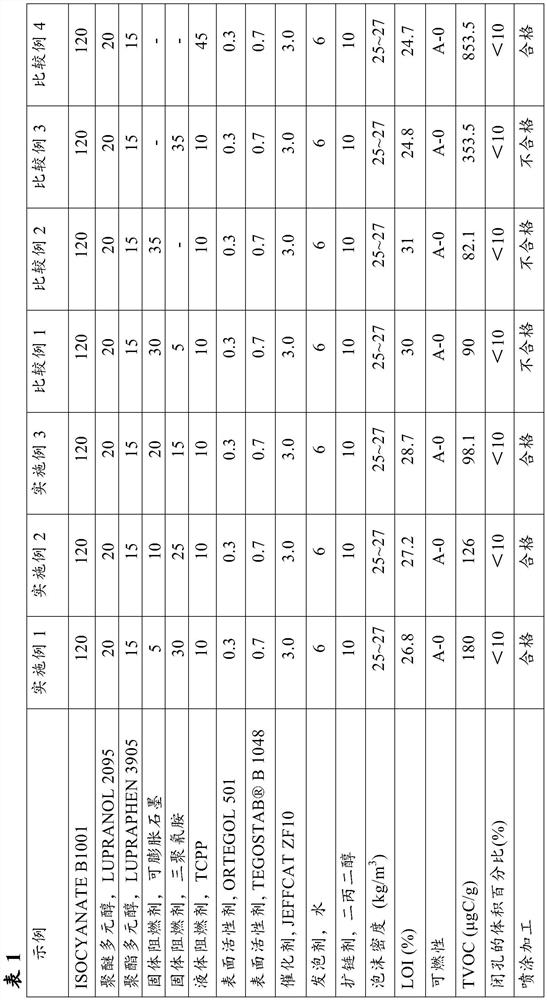

Embodiment 1

[0136] The following materials were mixed in 1 minute at a rate of 1800 rpm in the beaker, and a polyol blend was prepared: 20Glupranol 2095, 15G luPraphen 3905, 10g TCPP, 0.3g Ortegol 501, 0.7g B 1048, 10G DPG, 3.0G Jeffcat ZF10 and 6G water. Then, 5 g of expandable graphite was added to the mixture and mixed with a mixture of 1800 rpm for 3 minutes. 30 g of melamine was then added to the mixture, and stirred at 1800 rpm for 3 minutes. Finally, 120 g isocyanate B1001 was added, and the mixture was stirred at 1800 rpm for 5 seconds. Let the foam originated in free start conditions.

Embodiment 2

[0138] The following materials were mixed in 1 minute at a rate of 1800 rpm in the beaker, and a polyol blend was prepared: 20Glupranol 2095, 15G luPraphen 3905, 10g TCPP, 0.3g Ortegol 501, 0.7g B 1048, 10G DPG, 3.0G Jeffcat ZF10 and 6G water. Then, 10 g of expandable graphite was added to the mixture, and the mixture was stirred at 1800 rpm for 3 minutes. 25 g of melamine was added to the mixture, and stirred at 1800 rpm for 3 minutes. Finally, 120 g isocyanate B1001 was added, and the mixture was stirred at 1800 rpm for 5 seconds. Let the foam originated in free start conditions.

Embodiment 3

[0140] The following materials were mixed in 1 minute at a rate of 1800 rpm in the beaker, and a polyol blend was prepared: 20Glupranol 2095, 15G luPraphen 3905, 10g TCPP, 0.3g Ortegol 501, 0.7g B 1048, 10G DPG, 3.0G Jeffcat ZF10 and 6G water. Then, 20 g of expandable graphite was added to the mixture, and the mixture was stirred at 1800 rpm for 3 minutes. 15 g of melamine was then added to the mixture, and stirred at 1800 rpm for 3 minutes. Finally, 120 g isocyanate B1001 was added, and the mixture was stirred at 1800 rpm for 5 seconds. Let the foam originated in free start conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com