Environmentally friendly silane-modified adhesive and its preparation method and application

A silane modification and adhesive technology, applied in the direction of adhesives, polyether adhesives, adhesive types, etc., can solve the problems of high TVOC value, unable to meet the technical requirements of lightweight automobiles, and not environmentally friendly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

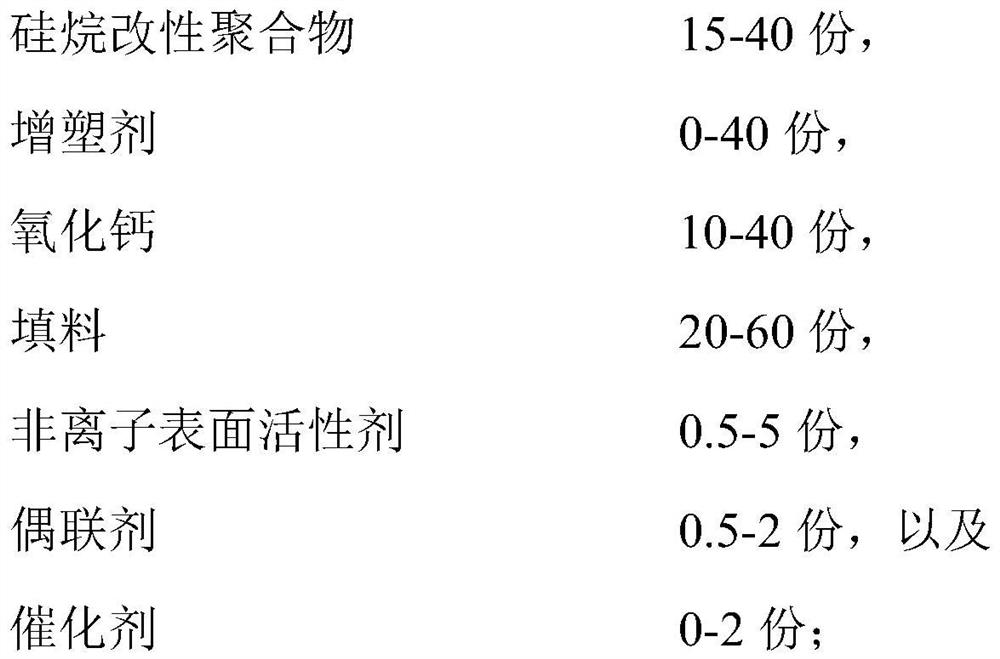

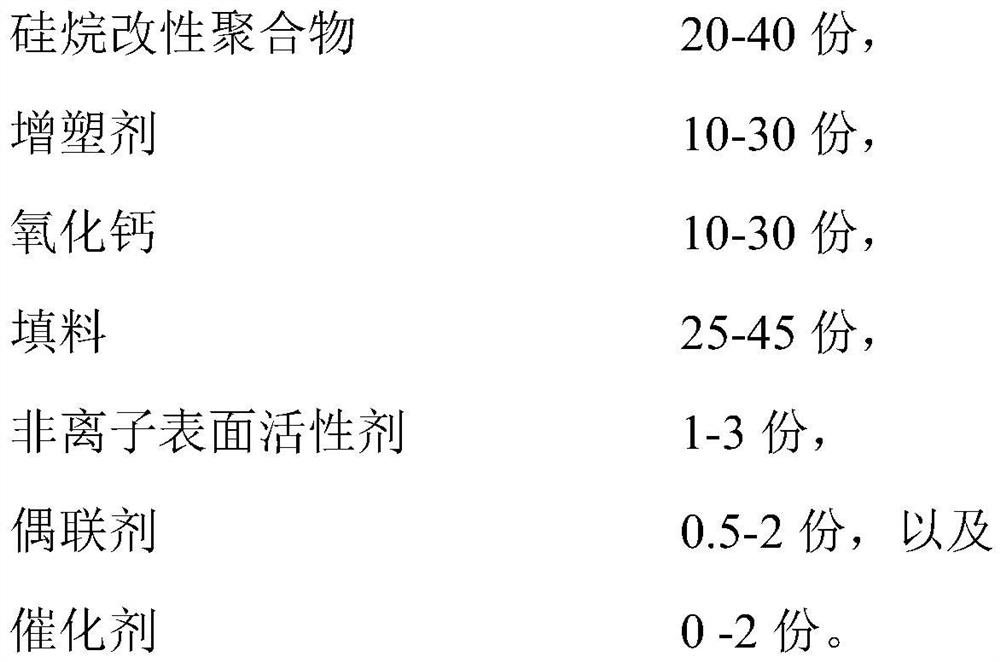

Method used

Image

Examples

Embodiment 1

[0049] This embodiment provides an environmentally friendly silane-modified adhesive, which is prepared from the following raw materials in parts by weight: 30 parts of silane-modified polymer S303H, 10 parts of diisononyl phthalate (DINP), 10 parts of calcium oxide, 45 parts of nano calcium carbonate, 0.5 parts of vinyl trimethoxysilane, 2 parts of propylene glycol block polyether (L64, HBL=13), 0.5 parts of γ-aminopropyl trimethoxysilane, 0.5 parts of N - β-aminoethyl-γ-aminopropyltrimethoxysilane, 0.2 part of light stabilizer TINUVIN 329, 0.2 part of UV absorber TINUVIN 770DF and 0.5 part of chelated tin.

[0050] The preparation method of the environment-friendly silane-modified adhesive of the present embodiment comprises the following steps:

[0051] S1. Weigh each raw material according to the composition of the environment-friendly silane-modified adhesive.

[0052]S2, add silane-modified polymer S303H, DINP, calcium oxide, propylene glycol block polyether L64, light ...

Embodiment 2

[0055] This embodiment provides an environmentally friendly silane-modified adhesive, which is prepared from the following raw materials in parts by weight: 20 parts of silane-modified polymer SAT350, 20 parts of polyether polyol, 30 parts of calcium oxide, 25 parts Nano-calcium carbonate, 0.2 parts of vinyltrimethoxysilane, 1 part of fatty alcohol polyoxyethylene ether (MOA-7, HLB=12-13), 1 part of N-β-aminoethyl-γ-aminopropyl trimethoxy base silane, 0.2 part of light stabilizer TINUVIN 329, 0.2 part of UV absorber TINUVIN 770DF and 0.5 part of chelated tin.

[0056] The preparation method of the environment-friendly silane-modified adhesive of the present embodiment comprises the following steps:

[0057] S1. Weigh each raw material according to the composition of the environment-friendly silane-modified adhesive.

[0058] S2, add silane-modified polymer SAT350, polyether polyol, calcium oxide, fatty alcohol polyoxyethylene ether (MOA-7), light stabilizer TINUVIN 329, and u...

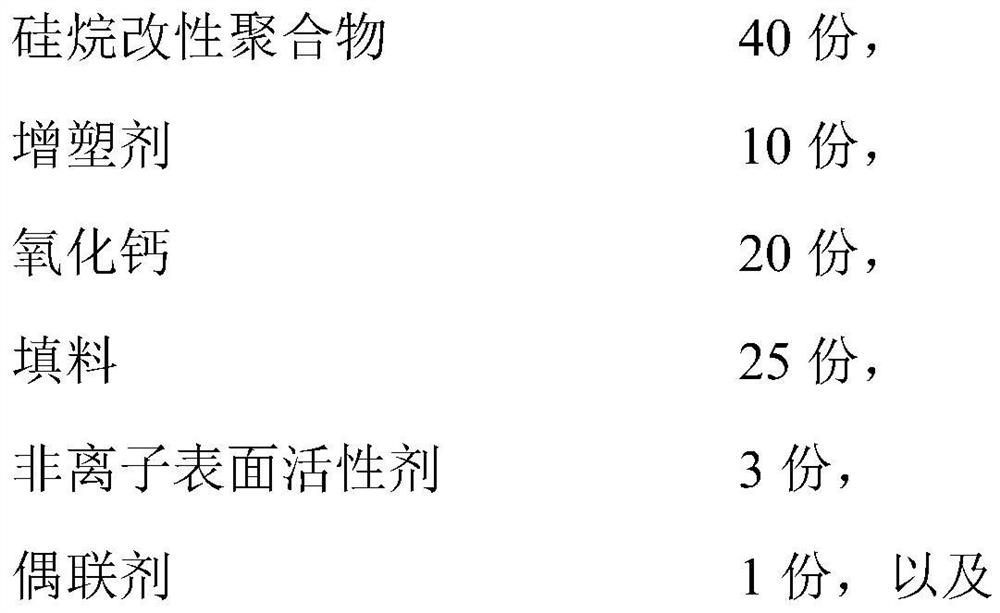

Embodiment 3

[0061] This embodiment provides an environmentally friendly silane-modified adhesive, which is prepared from the following raw materials in parts by weight: 40 parts of silane-modified polymer 12000DS, 10 parts of phenyl sulfonate, 20 parts of calcium oxide, 25 parts of heavy calcium carbonate (particle size 800-3000 mesh), 0.1 part of p-toluenesulfonyl isocyanate, 3 parts of polyoxyethylene sorbitan monolaurate (T-20, HLB=15), 0.5 part of γ - Aminopropyltrimethoxysilane, 0.5 part of γ-(2,3-glycidoxy) propyltrimethoxysilane, 0.2 part of light stabilizer TINUVIN 329, 0.2 part of UV absorber TINUVIN 770DF and 0.5 part of di Butyl tin dilaurate.

[0062] The preparation method of the environment-friendly silane-modified adhesive of the present embodiment comprises the following steps:

[0063] S1. Weigh each raw material according to the composition of the environment-friendly silane-modified adhesive.

[0064] S2, the silane modified polymer 12000DS, alkyl sulfonate phenyl est...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com