A low-ratio two-component dealcoholized silicone sealant and its preparation method and application

A two-component, dealcoholized technology, applied in adhesives, adhesive types, non-polymer adhesive additives, etc., can solve poor curing or bonding, slow substrate sticking speed, bonding failure, etc. problems, achieve the effect of reducing non-curing or poor bonding, simple production process, and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

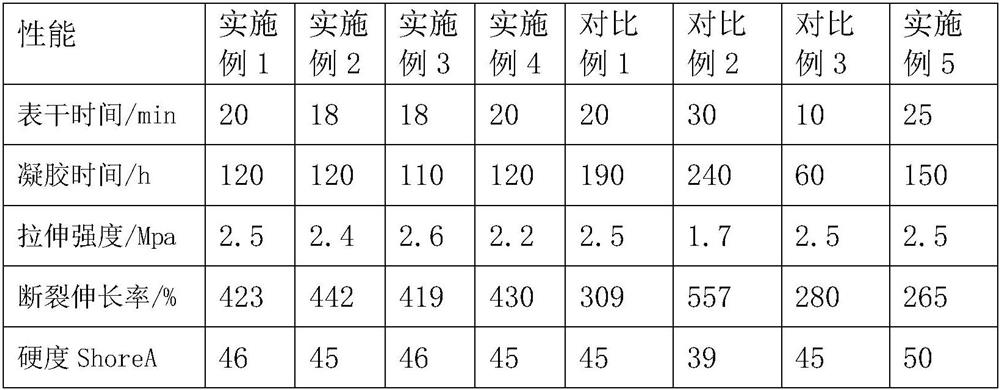

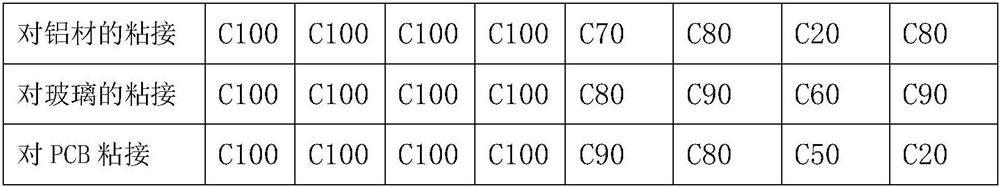

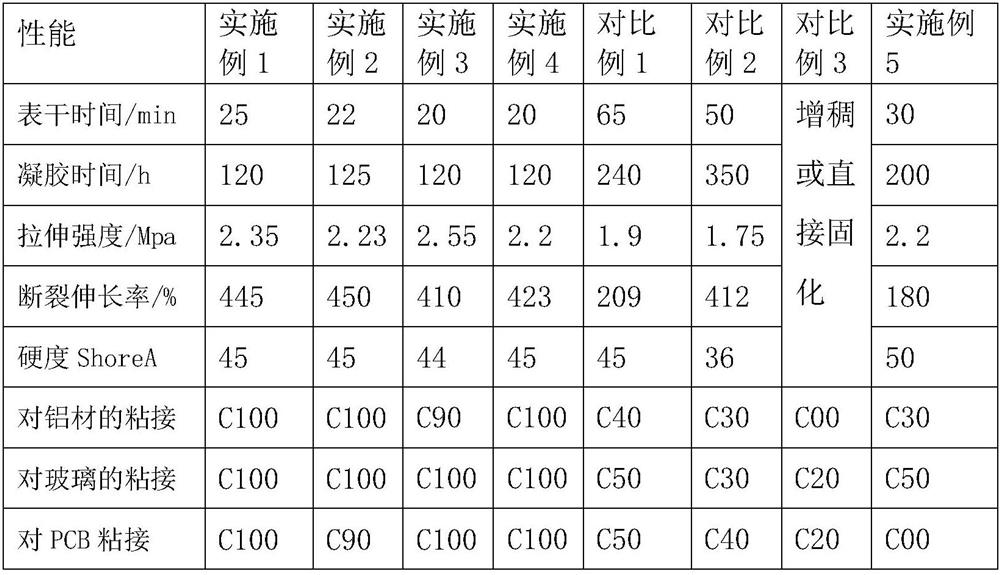

Examples

Embodiment 1

[0034] Example 1 Preparation of low-ratio two-component dealcoholized silicone sealant

[0035] 1) Preparation of component A: 60 parts of α, ω-terminated hydroxyl polydimethylsiloxane with a viscosity of 20000mpa.s and a specific surface area of 18-20m 2 60 parts / g of nano-calcium carbonate, 5 parts of KH560 modified silicon powder with a particle size of 5 μm, mixed and stirred evenly and heated to 130 ° C, and defoamed for 1 hour, the rotation speed was 1000 rpm, the vacuum degree was -0.09Mpa, and cooled to <40 ° C to obtain A component.

[0036] 2) Preparation of component B: 60 parts of alkoxy-terminated polydimethylsiloxane with a specific surface area of 18-20m 2 60 parts / g of nano-calcium carbonate, 5 parts of KH560 modified silicon powder with a particle size of 5 μm are dispersed and mixed evenly at high speed, heated to 130 ° C, vacuumed for 1 hour, cooled to room temperature (<30 ° C) under vacuum, and added Ethyl orthosilicate, 10 parts of polymethyltrietho...

Embodiment 2

[0039] 1) Preparation of component A: 35 parts of α, ω-terminated hydroxyl polydimethylsiloxane with a viscosity of 80000mpa.s and a specific surface area of 18-20m 2 40 parts of nano-calcium carbonate / g, 5 parts of KH560 modified silicon powder with a particle size of 5 μm, and 10 parts of terminal methyl polydimethylsiloxane with a viscosity of 350 mpa.s, mix and stir evenly and heat up to 110 ° C, and defoam 2h, the rotation speed is 100rpm, the vacuum degree is -0.09Mpa, and cooled to <40°C to obtain component A.

[0040]2) Component B is prepared: 30 parts of alkoxy-terminated polydimethylsiloxane, the specific surface area of the reinforcing filler is 18-20m 2 20 parts / g of nano-calcium carbonate, 15 parts of KH560 modified silicon powder with a particle size of 5 μm, dispersed and mixed evenly at a high speed, heated up to 110 ° C, vacuumed for 2 hours, cooled to room temperature (<30 ° C) under vacuum, and added positive Ethyl silicate, 4 parts of polymethyltrieth...

Embodiment 3

[0043] 1) A component is prepared: 50 parts of α, ω-hydroxyl-terminated polydimethylsiloxane with a viscosity of 20000mpa.s and 80000mpa.s (molar ratio 1:1) and a specific surface area of 18-20m 2 55 parts per gram of nano-calcium carbonate, 10 parts of KH560 modified silica powder with a particle size of 5 μm, and 5 parts of terminal methyl polydimethylsiloxane with a viscosity of 350 mpa.s, mix and stir evenly and heat up to 110 ° C, and defoam 2h, the rotation speed is 600rpm, the vacuum degree is -0.09Mpa, and cooled to <40°C to obtain component A.

[0044] 2) Preparation of component B: 60 parts of alkoxy-terminated modified polyether resin with a specific surface area of 18-20m 2 45 parts per gram of nano-calcium carbonate, 5 parts of KH560 modified silicon powder with a particle size of 3 μm, and 10 parts of silicon powder with a particle size of 5 μm, disperse and mix evenly at high speed, heat up to 110 ° C, vacuumize for 2 hours, and cool to At room temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com