Silicone Condensed Two-Component Potting Adhesive and Its Application

A condensation type, two-component technology, used in the field of potting glue, can solve the problems of low light output efficiency and poor light quality, and achieve the effect of broad application market, small color temperature shift and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

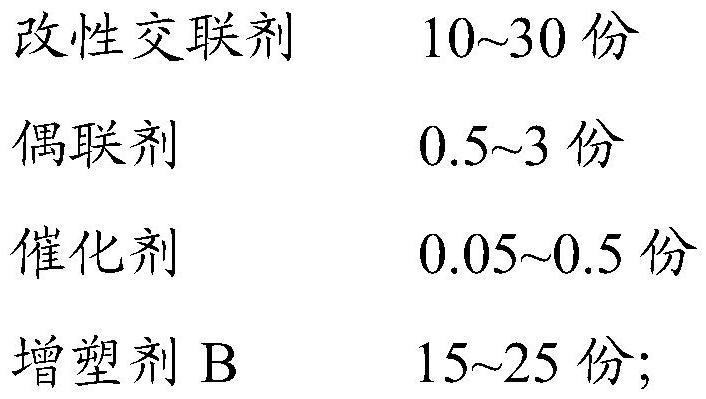

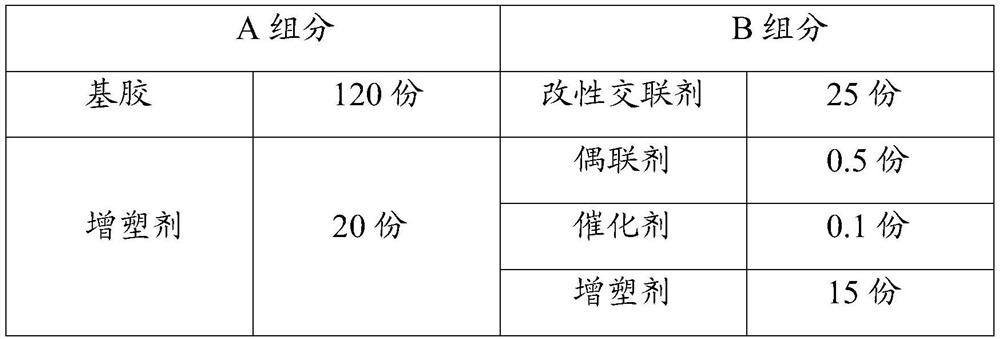

[0037] A silicone condensation-type two-component potting glue of this embodiment has a raw material formula as follows in parts by weight:

[0038]

[0039] The base glue of the above formula A component is 50000mPa.s double-ended hydroxypolymethylsiloxane (107 glue of 50000mPa.s), and the plasticizer is 100mPa.s double-ended methylpolysiloxane (100mPa .s methyl silicone oil), the viscosity of component A after mixing is 12000mPa.s.

[0040] In component B of the above formula, the modified crosslinking agent is polymethyltrimethoxysilane (commercially available NP31, the degree of polymerization is 3-6), the coupling agent is 3-aminopropyltriethoxysilane, and the catalyst is di Dibutyltin acetate, the plasticizer is 500mPa.s double-ended methyl polymethylsiloxane, and the mixed viscosity of component B is 220mPa.s.

[0041] The method for preparing and using the above-mentioned silicone condensation type two-component encapsulant comprises the following steps:

[0042] ...

Embodiment 2

[0048] A silicone condensation-type two-component potting glue of this embodiment has a raw material formula as follows in parts by weight:

[0049]

[0050] Component A of the above formula is 80000mPa.s double-ended hydroxypolymethylsiloxane (80000mPa.s 107 glue), plasticizer is 350mPa.s double-ended methylpolysiloxane (350mPa .s methyl silicone oil), the viscosity of component A after mixing is 14500mPa.s.

[0051] In component B of the above formula, the modified crosslinking agent is polymethyltriethoxysilane (commercially available CJ-8300, the degree of polymerization is 3-6), and the coupling agent is 3-glycidyl etheroxypropyltrimethoxy Silane, the catalyst is dibutyltin diacetate, the plasticizer is 500mPa.s double-ended methyl polymethylsiloxane, and the mixed viscosity of component B is 268mPa.s.

[0052] The method for preparing and using the above-mentioned silicone condensation type two-component encapsulant comprises the following steps:

[0053] Preparatio...

Embodiment 3

[0059] A silicone condensation-type two-component potting glue of this embodiment has a raw material formula as follows in parts by weight:

[0060]

[0061] The above-mentioned formula A component base glue is 50000mPa.s double-ended hydroxypolymethylsiloxane (107 glue of 50000mPa.s), and the plasticizer is 350mPa.s double-ended methylpolymethylsiloxane ( 350mPa.s methyl silicone oil), the viscosity of component A after mixing is 14500mPa.s.

[0062] In component B of the above formula, the modified cross-linking agent is polymethyltriethoxysilane (commercially available CJ-8300, the degree of polymerization is 3-6), and the coupling agent is 3-glycidyl ether oxypropyl methyl di Methoxysilane, the catalyst is dibutyltin dilaurate, the plasticizer is 350mPa.s double-ended methyl polymethylsiloxane, and the mixed viscosity of component B is 218mPa.s.

[0063] The method for preparing and using the above-mentioned silicone condensation type two-component encapsulant comprises ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com