Special seal gum for solar cell assembly and manufacturing method thereof

A solar cell and sealant technology, which is applied in the direction of electrical components, chemical instruments and methods, circuits, etc., can solve the problems of insufficient aging performance and difficulty in meeting the use requirements of solar modules, and achieve excellent manufacturability, good sealing, and fast speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 150 kg of hydroxypropyltrimethoxysilane and 100 kg of calcium carbonate into a multifunctional dispersing mixer and stir at a speed of 300 rpm for 2 hours. Add 10kg of phosphite anti-aging agent, 10kg of silicon dioxide, 8kg of isopropyl titanate and 0.5kg of dibutyltin dilaurate into the multifunctional dispersing mixer in batches, mix with the above-mentioned hydroxypropyltrimethoxysilane mixture, Fully stir for 5 hours to obtain a special sealant for solar cell modules.

Embodiment 2

[0030] Add 200 kg of hydroxypropylmethyldiethoxysilane and 75 kg of talc powder into a multifunctional dispersing mixer and stir at a speed of 350 rpm for 3 hours. Add 5kg of diphenylamine antioxidant, 15kg of carbon black, 4.5kg of r-aminopropyltriethoxysilane and 0.8kg of dibutyltin diacetate into the multifunctional dispersing mixer in batches, and mix with the above-mentioned hydroxypropylmethyl diacetate The ethoxysilane mixture was mixed and fully stirred for 6 hours to obtain a special sealant for solar cell modules.

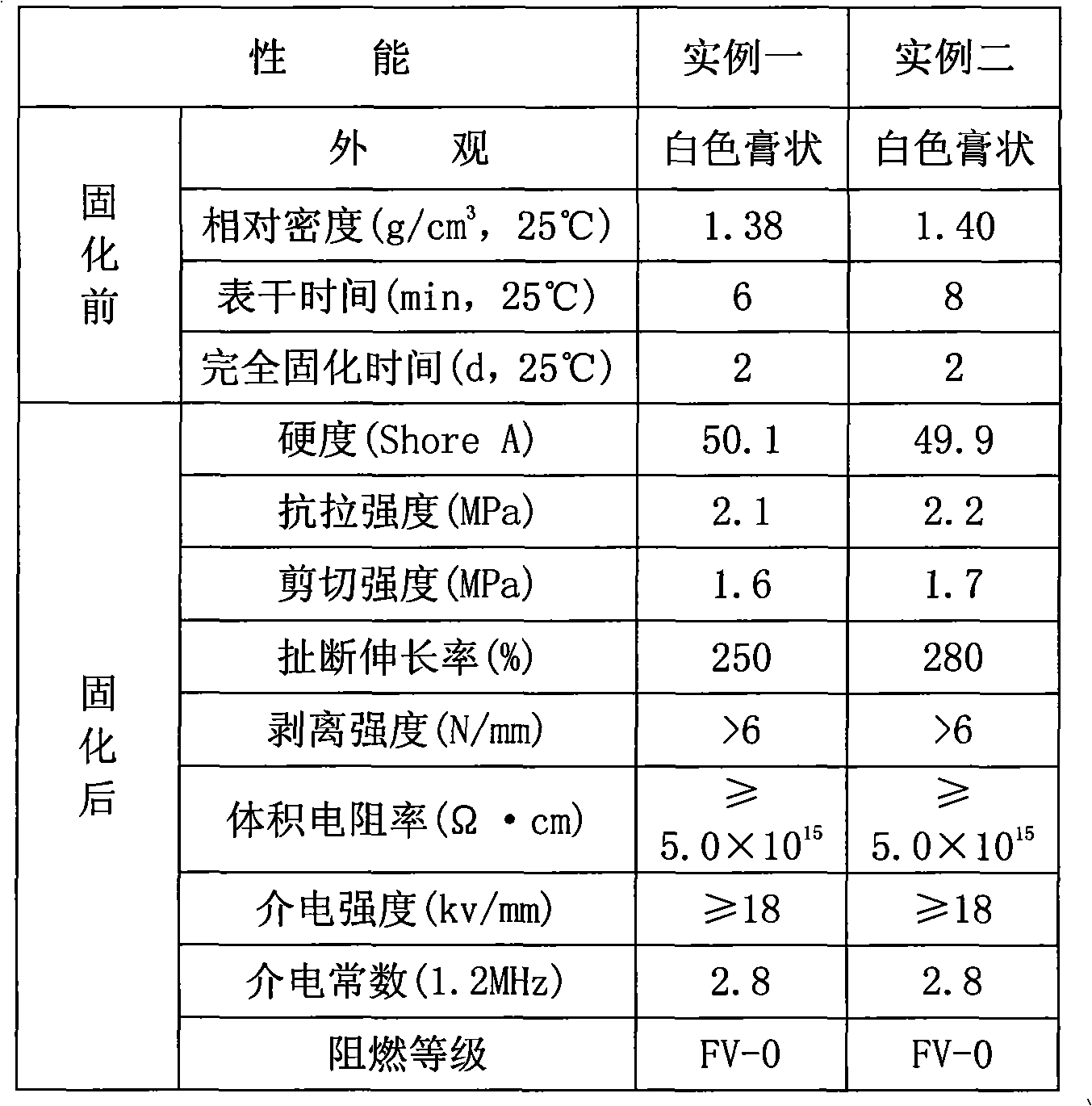

[0031] The actual detection result of the embodiment of the present invention is as shown in table 1,

[0032] Table 1 Test results

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com